Method for preparing high-loading catalyst Pt/CNTs

A high-load, catalyst technology, used in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. Low cost, simple process and environment-friendly effect

Inactive Publication Date: 2010-06-02

BEIJING UNIV OF TECH

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Generally speaking, the amount of platinum loaded on a Pt catalyst is generally between 20% and 60%. Therefore, under the same amount of Pt utilization, the lower the Pt loading, the thicker the electrode catalyst layer, so that the reaction substances (fuel or O 2 ) is limited by mass transfer

Moreover, agglomeration is prone to occur during the preparation of high-loaded Pt catalysts, making it challenging to prepare high-loaded Pt catalysts.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

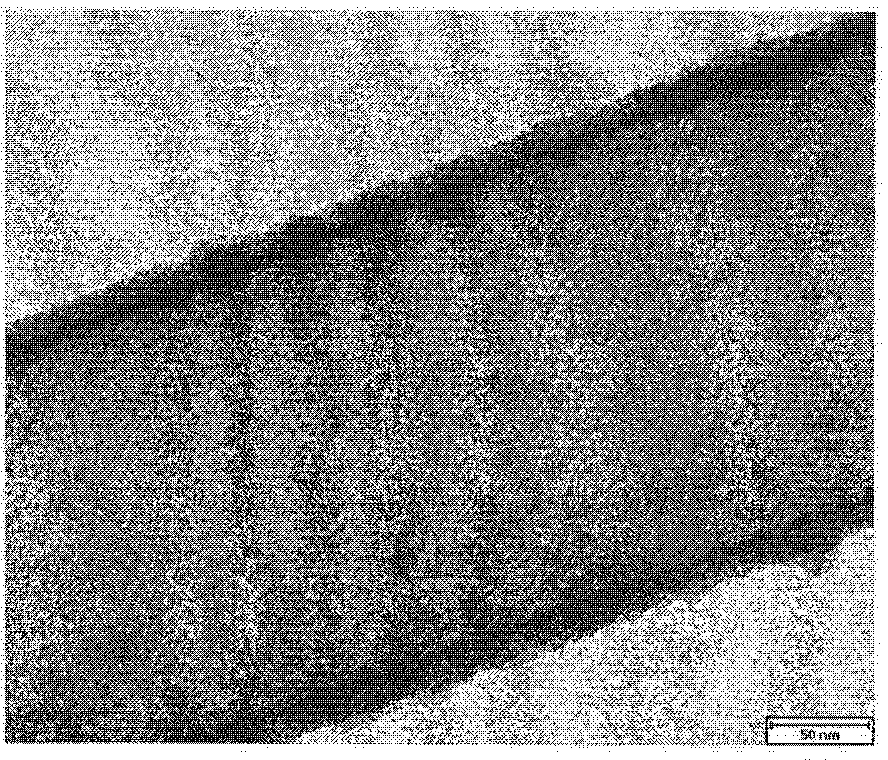

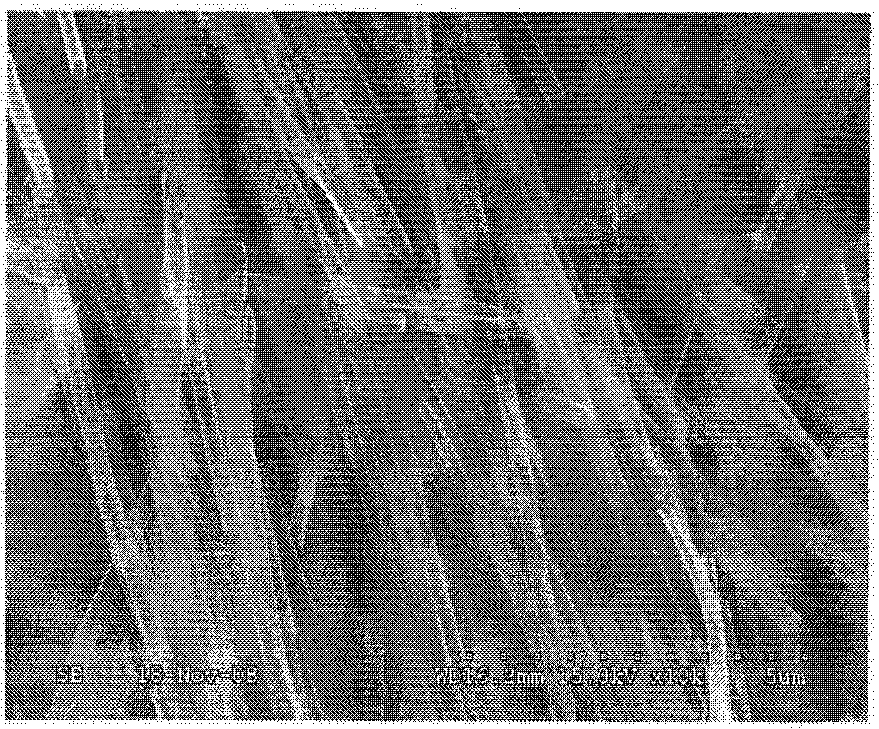

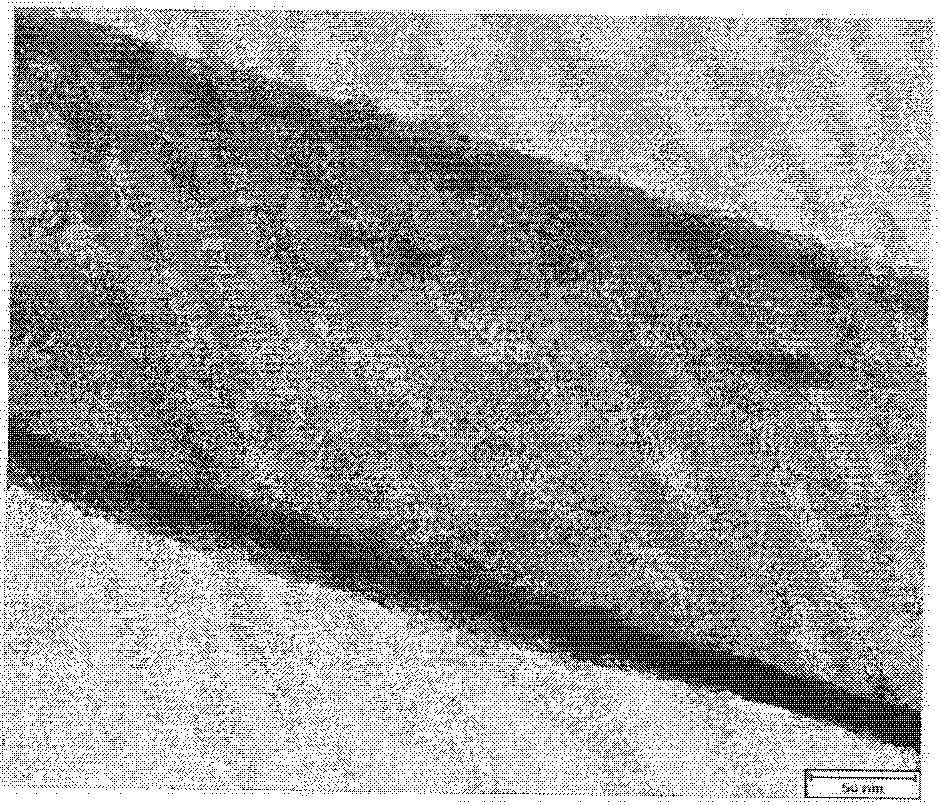

The invention belongs to the field of fuel cells, and relates to a method for preparing a high-loading catalyst Pt / CNTs, which comprises the following steps of: preparing 50g / l solution of glucose; transferring the prepared solution of glucose into a reaction kettle, adding an AAO template into the reaction kettle, reacting for 8h at the temperature of 160 DEG C, taking the template out, repeatedly washing the template to be clean with distilled water, then performing carbonization treatment on the template for 3 hours in nitrogen atmosphere at the temperature of 700 DEG C, and dissolving the template in solution of NaOH to obtain CNTs with two open ends and regular arrangement; and mixing the prepared CNTs and 10g / l H2PtCl6 in the mass ratio of 26 to 1, uniformly stirring the mixture, standing the mixture for 2 to 32 days, and then performing heating reflux for 4h to obtain the high-loading catalyst Pt / CNTs. The method realizes the self-reduction, reduces Pt metal salt to Pt nano-particles, and prepares the high-loading catalyst Pt / CNTs by adjusting standing time; and the catalyst has good electro-catalytic performance on the reduction of oxygen.

Description

technical field The invention relates to a preparation method of a platinum catalyst with a high loading capacity for direct methanol fuel cell cathode oxygen reduction, and belongs to the field of fuel cell material science and technology and the field of electrocatalysis technology. Background technique Since the discovery of carbon nanotubes in 1991, carbon nanotubes have been considered as a very good electrocatalyst carrier for the preparation of direct Catalysts for Methanol Fuel Cells [1] .Using multi-walled carbon nanotubes (MWCNT) and single-walled carbon nanotubes (SWCNT) as supports can uniformly disperse noble metal and its alloy nanoparticles on carbon nanotubes, and the resulting electrocatalysts show good electrocatalysts in DMFC. catalytic performance. However, due to the hydrophobicity of its surface, the loading process is not easy to carry out. Generally, it needs to be functionalized in the early stage, such as boiling or heating for several hours with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J31/30H01M4/88H01M4/92

CPCY02E60/50

Inventor 张丽娟田瑞丽胡朴夏定国

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com