Method and apparatus for preparing blue tungsten oxide by ammonium paratungstate self-reduction

A technology of blue tungsten oxide and ammonium paratungstate, which is applied in the field of preparing blue tungsten oxide by self-reduction of ammonium paratungstate, can solve problems such as affecting health, air pollution, and increasing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

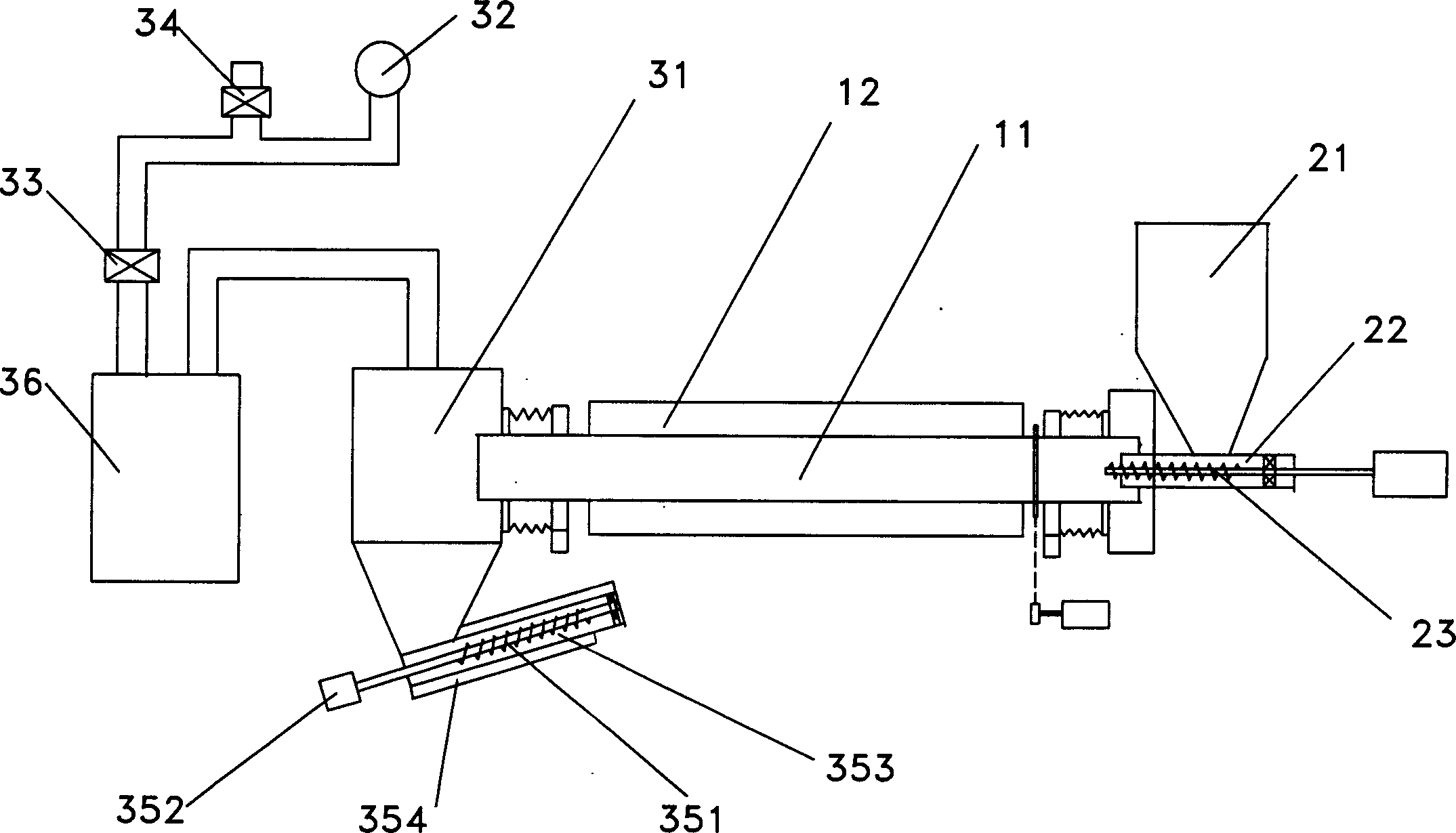

[0029] Embodiment one, see figure 1 Shown, a kind of ammonium paratungstate of the present invention prepares the method for blue tungsten oxide, is to use ammonium paratungstate 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O is the raw material, and in a well-sealed container, that is, a furnace tube, feed ammonium paratungstate 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O, heat the furnace tube, and ammonium paratungstate 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O is heated and decomposed into tungsten trioxide WO 3 , Ammonia NH 3 and water vapor H 2 O, its chemical reaction formula is as follows:

[0030]

[0031] In the furnace tube, make full use of tungsten oxide WO X is ammonia NH 3 Decomposition of good catalytic properties, the above thermal decomposition of ammonia NH 3 further decomposed into nitrogen gas N 2 and hydrogen H 2 , and its chemical reaction formula is as follows:

[0032]

[0033] Then by controlling a certain reaction temperature and proper furnace gas pressure, in t...

Embodiment 2

[0045] Embodiment two, see figure 1 Shown, a kind of method of ammonium paratungstate of the present invention prepares blue tungsten oxide, and the difference of embodiment one is that ammonium paratungstate 5 (NH 4 ) 2 O·12WO 3 ·5H 2 When O is heated, its heating temperature is set at 600°C; while the reaction temperature in the furnace tube is set at 750°C; the furnace gas pressure is adjusted to 1.5 mbar.

Embodiment 3

[0046] Embodiment three, see figure 1 Shown, a kind of method of ammonium paratungstate of the present invention prepares blue tungsten oxide, and the difference of embodiment one is that ammonium paratungstate 5 (NH 4 ) 2 O·12WO 3 ·5H 2 When O is heated, its heating temperature is set at 500°C; while the reaction temperature in the furnace tube is set at 650°C; the pressure of the furnace gas is adjusted to 0.5 mbar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com