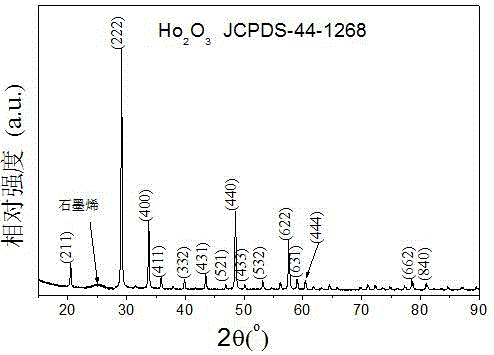

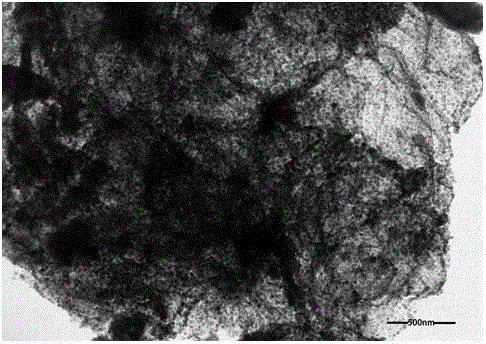

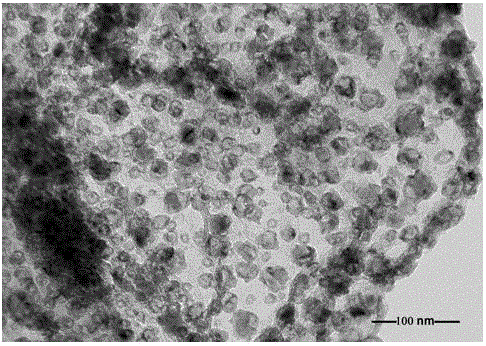

Preparation method of rare earth oxide and graphene nanocomposite material

A nanocomposite material, rare earth oxide technology, applied in rare earth metal oxides/hydroxides, rare earth metal compounds, chemical instruments and methods, etc., can solve the problem of poor crystallization of rare earth oxides, unfavorable commercial synthesis, and poor product stability and other problems, to achieve the effect of low synthesis temperature, unique structural characteristics and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 0.2445 g of holmium oxide, add it to 10 ml of 1:4 nitric acid solution, heat to dissolve, continue heating to remove excess nitric acid to obtain a weakly acidic holmium nitrate solution, and then add it to 400 ml with a concentration of 0.5 g / L Add 0.1084 g of glycine to the aqueous dispersion of graphene oxide, stir and sonicate for 30 minutes to obtain a mixed dispersion, heat to viscous, put it into a muffle furnace with a temperature of 500 ° C to ignite, after the combustion is completed, cool To room temperature, promptly obtain nanometer holmium oxide / graphene nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com