Cooper-containing mesoporous adsorbent preparation method, and prepared adsorbent and applications thereof

An adsorbent and copper mesoporous technology, which is applied in the field of preparation of copper-containing mesoporous adsorbents, can solve problems such as unfavorable cuprous oxide dispersion and oxide aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

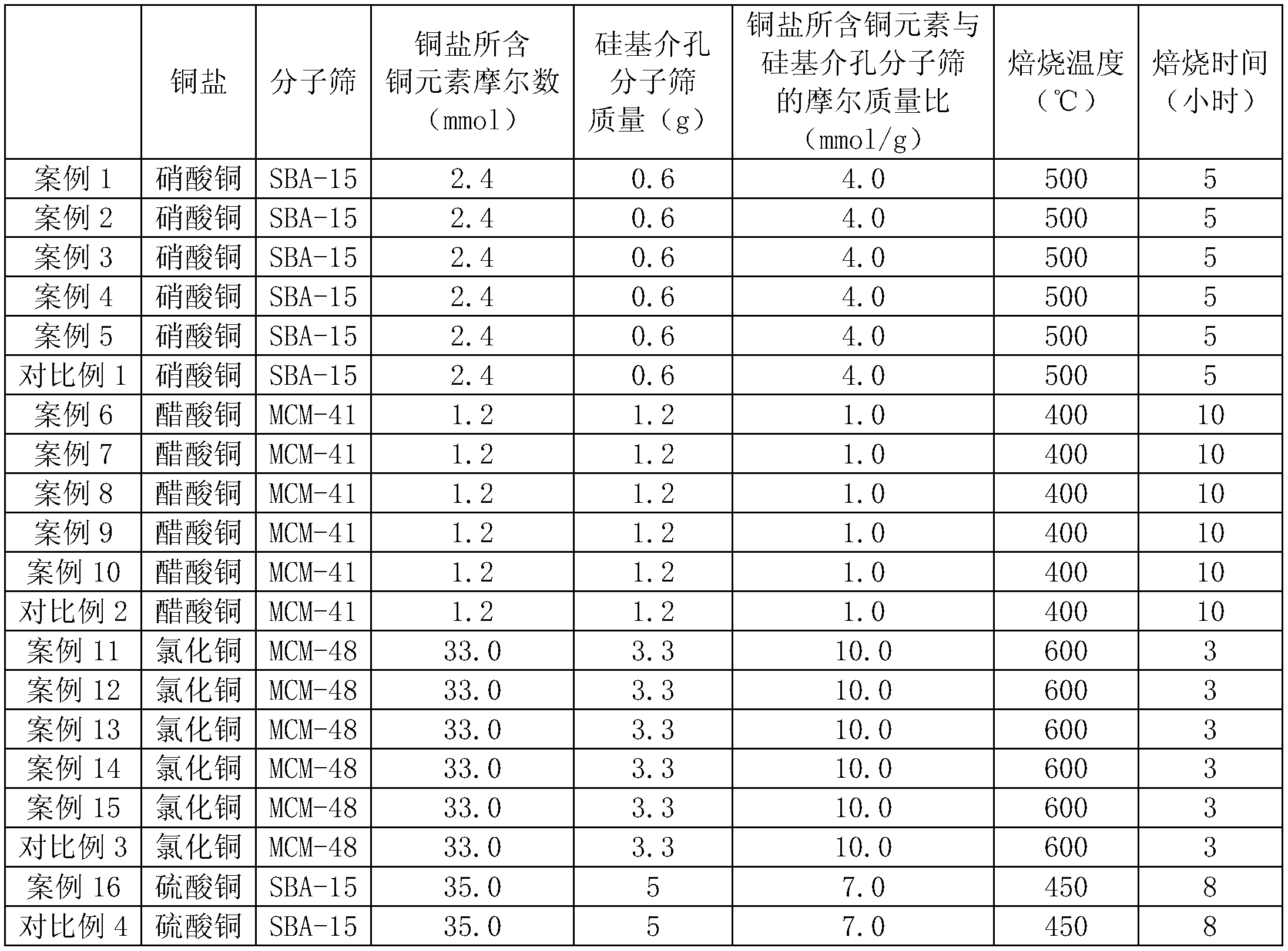

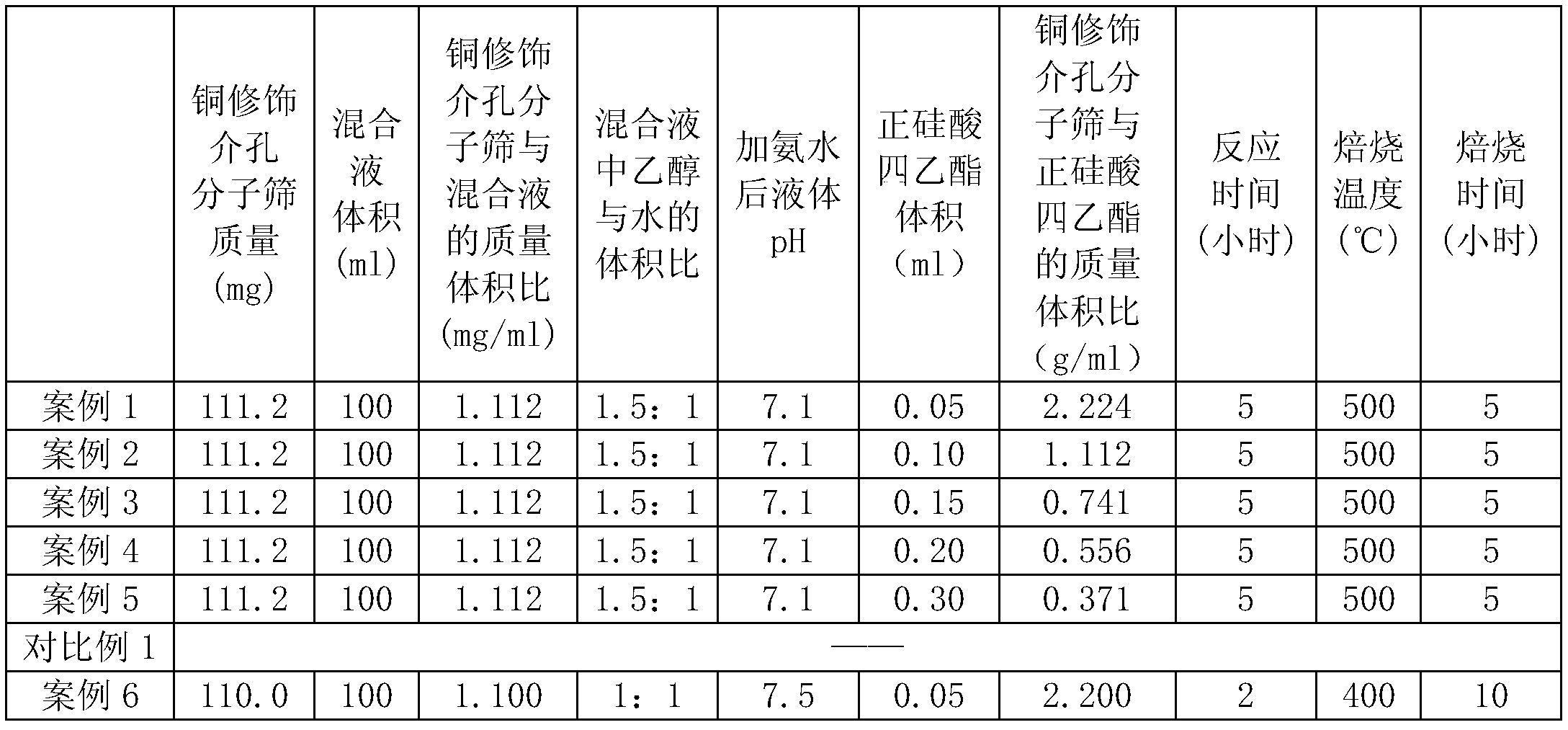

[0026] Example 1 Preparation of copper-containing mesoporous adsorbent

[0027] The preparation method of copper-containing mesoporous adsorbent in this embodiment is as follows:

[0028] In the first step, the copper salt is first ground, and then silicon-based mesoporous molecular sieve is added and fully ground to obtain a mixture; the mixture is roasted to obtain the copper-modified mesoporous molecular sieve.

[0029] Among them, the copper salt is at least one of copper nitrate, copper acetate, copper chloride, and copper sulfate, and the silicon-based mesoporous molecular sieve is one of SBA-15, MCM-41, and MCM-48. The molar mass ratio of the copper element contained in the copper salt to the silicon-based mesoporous molecular sieve is 1.0-10.0 mmol / g. The calcination is carried out in air atmosphere; the calcination temperature is 400°C-600°C, and the calcination time is 3-10 hours.

[0030] SBA-15 can be prepared by the following method: Dissolve 1 part by weight of...

Embodiment 2

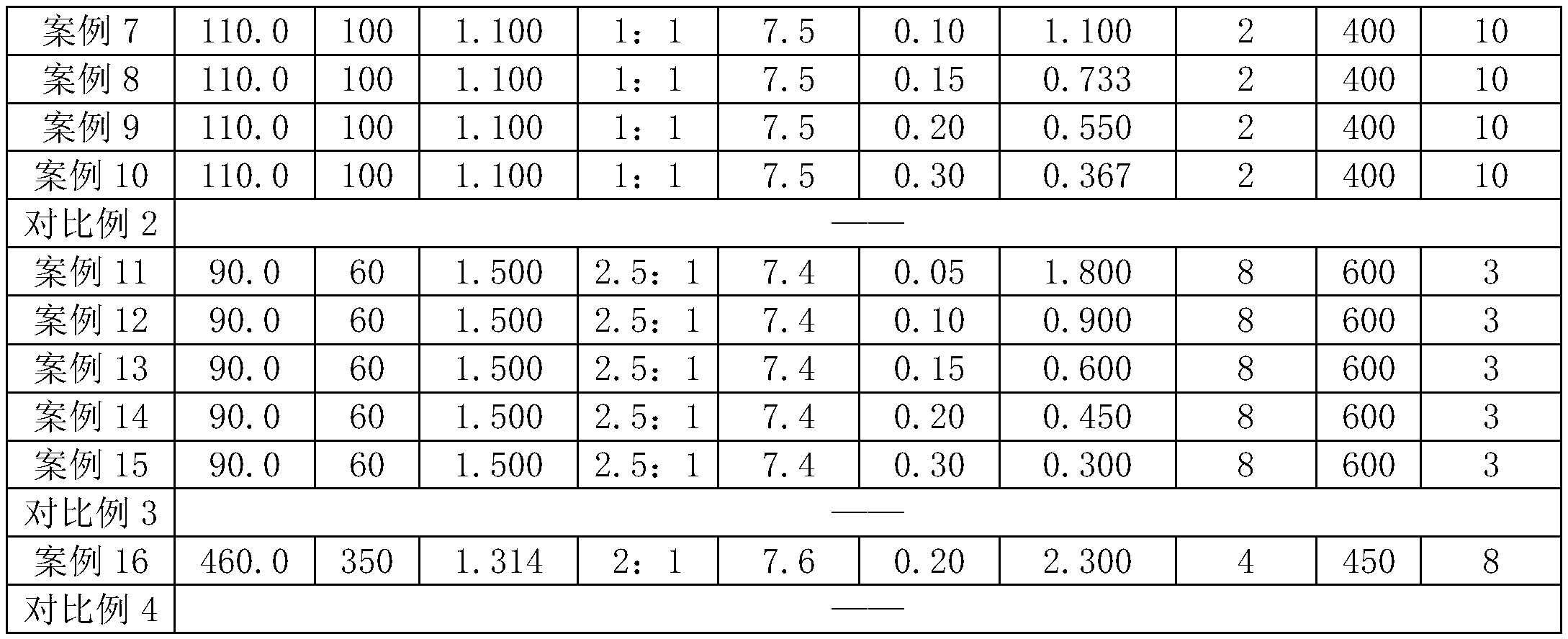

[0048] Embodiment 2 makes the gas adsorption performance of adsorbent

[0049] The gas adsorption performance of each adsorbent was determined by gravimetric method. Take 30 mg of adsorbent and place it in a high-precision gravimetric adsorption instrument Hiden IGA-100, fill it with carbon monoxide or ethylene gas at a rate of 10 mbar / min, and adsorb at 25 °C for 50 min at each pressure point. Finally, the adsorption amount was measured.

[0050] The results are shown in the table below:

[0051]

Carbon monoxide adsorption capacity (ml / g)

Ethylene adsorption capacity (ml / g)

Case 1

7.1849

7.2632

Case 2

9.1477

8.7857

Case 3

9.2587

9.2905

Case 4

10.0570

10.0821

Case 5

6.9348

7.5545

Comparative example 1

6.3475

6.4357

Case 6

7.5649

6.8971

Case 7

9.6523

7.3291

Case 8

9.8523

8.3541

Case 9

10.5560

9.5803

Case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com