Biomass gasification tar vapor translation hydrogen making catalyst and preparation method thereof

A catalyst and biomass technology, which is applied in the field of catalyst and preparation of tar in-situ catalytic steam reforming process, can solve the problems such as the reduction of the activity of the active component catalyst, the deactivation of the catalyst, etc., and achieve good activity stability and self-reduction performance. Effect

Inactive Publication Date: 2008-12-31

DALIAN UNIV OF TECH

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

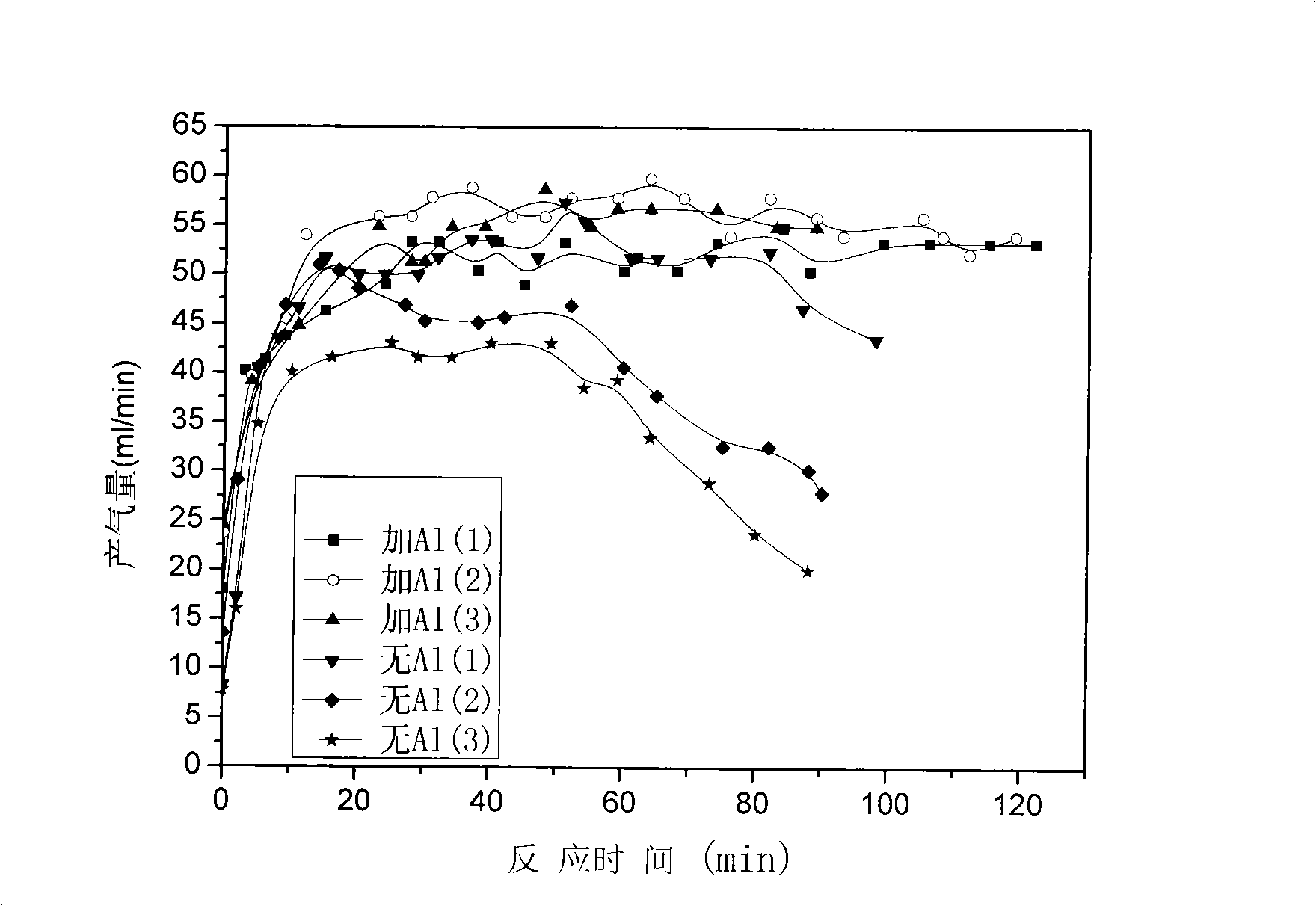

The disadvantage is that although the catalyst exhibits high activity at 480-650°C, the catalyst is prone to gradually deactivate during repeated use at around 800°C. The reason is that palygorskite itself dehydrates at high temperatures or its structure On the other hand, because the higher content of active components nickel and iron will migrate and grow under high temperature reducing conditions, the coalescence of active components will lead to the reduction of catalyst activity

On the other hand, the low-temperature reducibility and high-temperature activity stability of catalysts are a pair of contradictions, and they are also problems that need to be solved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] Below by embodiment the present invention will be further described, but do not affect protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Login to View More

Abstract

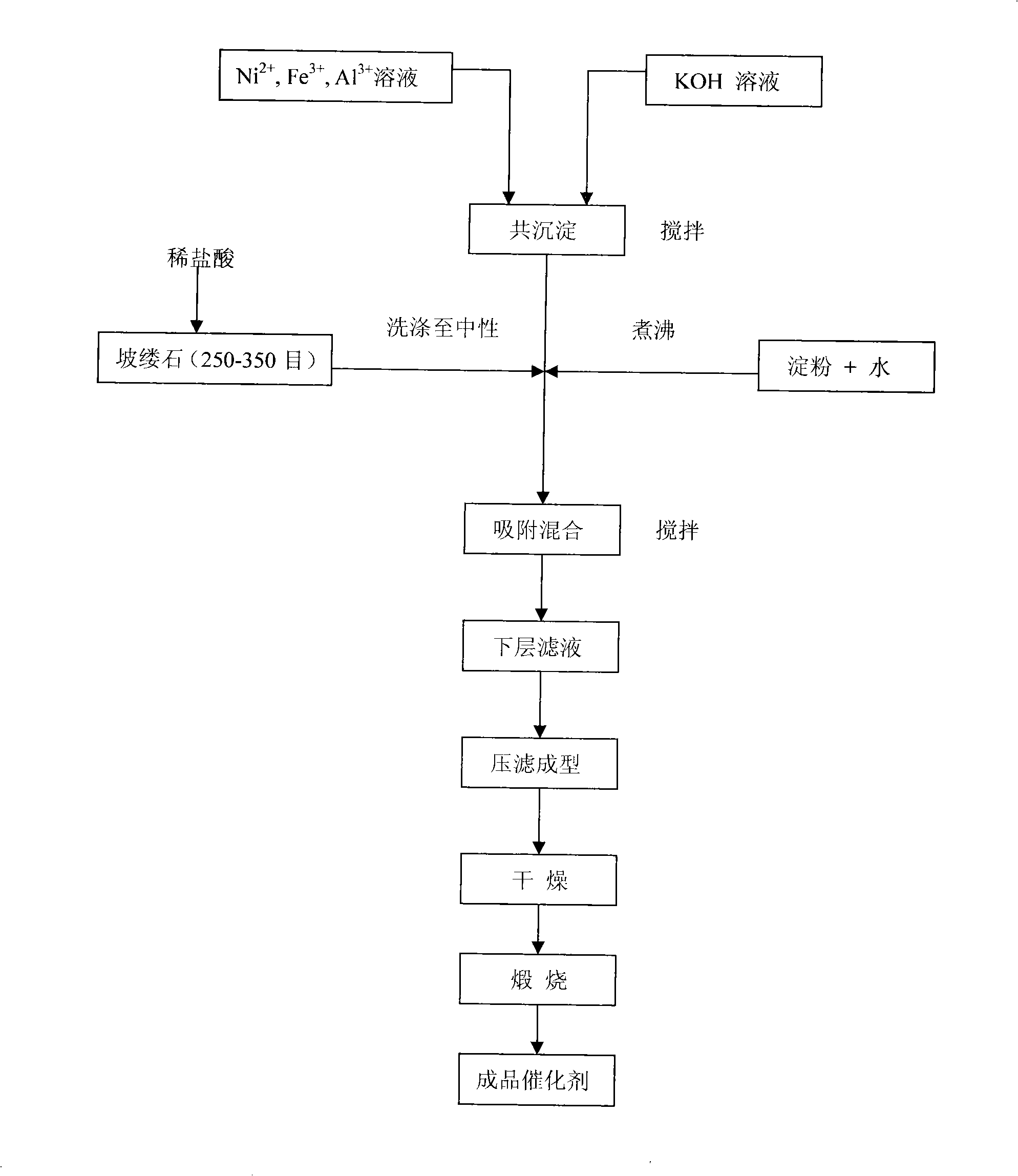

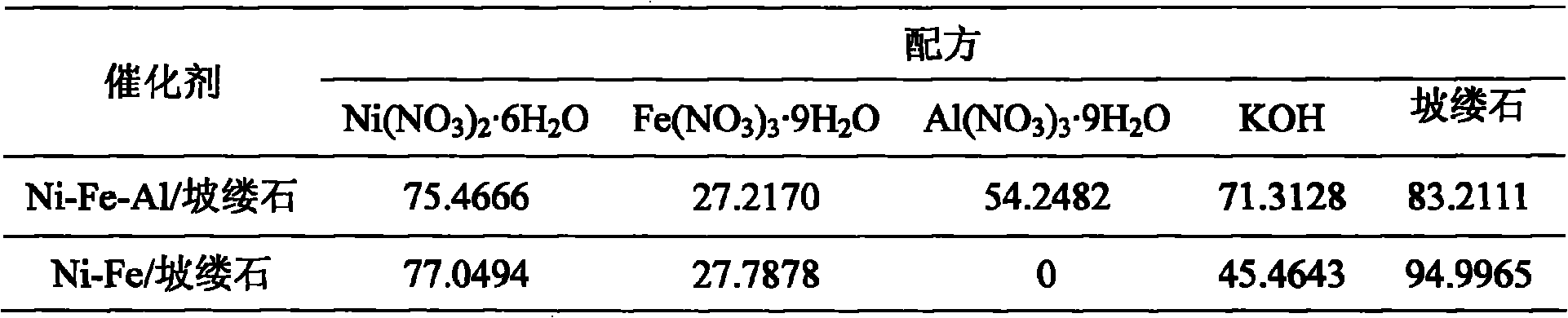

The invention belongs to the filed of energy sources and chemical industry and in particular relates to a catalyst used for hydrogen production from biomass gasified tar steam reforming and a preparation method thereof. The catalyst takes palygorskite as a carrier and nickel as a main active component for the steam reforming, and contains the promoter components such as iron, potassium, aluminum and the like, and the mass percentage of each component is as follows: the content of NiO is 3 - 30%, that of Fe2O3 is 3 - 20%, that of Al2O3 is 3 -2 5%, and that of K2O is 1 - 10%; the mass percentage of the palygorskite is 60 - 95%. The catalyst is prepared by a co-precipitation absorption method, in which the active components of nickel, iron, aluminum and potassium are loaded on the surface of the palygorskite in the manner of co-precipitation and absorption, and then are filtered, shaped, dried and calcined to obtain a finished catalyst. The catalyst has good activity stability and self-reduction property at the high temperature of 800 DEG C, is applicable to the steam reforming process of tar with biomass or coal gasified gas as a catalyst, and can also be used for hydrogen production reaction via hydrocarbon steam reforming.

Description

technical field [0001] The invention belongs to the field of energy and chemical industry, and in particular relates to a catalyst and a preparation method applicable to the in-situ catalyzed water vapor conversion process of tar in a recycled biomass moving bed gasification furnace or a fluidized bed gasification furnace. Background technique [0002] The present invention is an improvement of the prior art Chinese Invention Patent Publication CN 101172232A. CN 101172232A provides a Ni-Fe / palygorskite catalyst for steam conversion of biomass tar with low-temperature activity and a preparation method thereof. The disadvantage is that although the catalyst exhibits high activity at 480-650°C, the catalyst is prone to gradually deactivate during repeated use at around 800°C. Changes, on the other hand, because the higher content of active components nickel and iron will migrate and grow under high temperature reducing conditions, and the coalescence of active components will ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J23/78B01J21/16C01B3/34

Inventor 徐绍平于建华杨小芹徐海龙刘淑琴

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com