GMA welding contact tip having bushing

A gas shielded welding, contact tip technology, applied in electrode accessories, manufacturing tools, welding rod characteristics, etc., can solve problems such as inability to weld, reduce replacement or purchase costs, improve service life, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

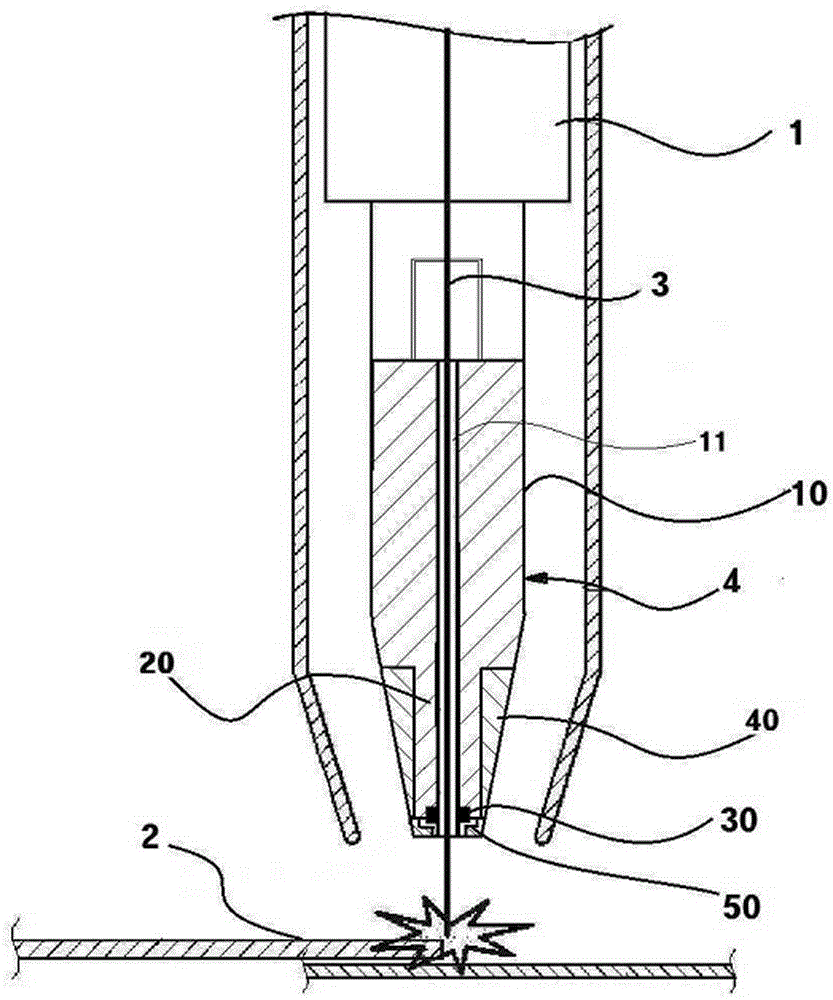

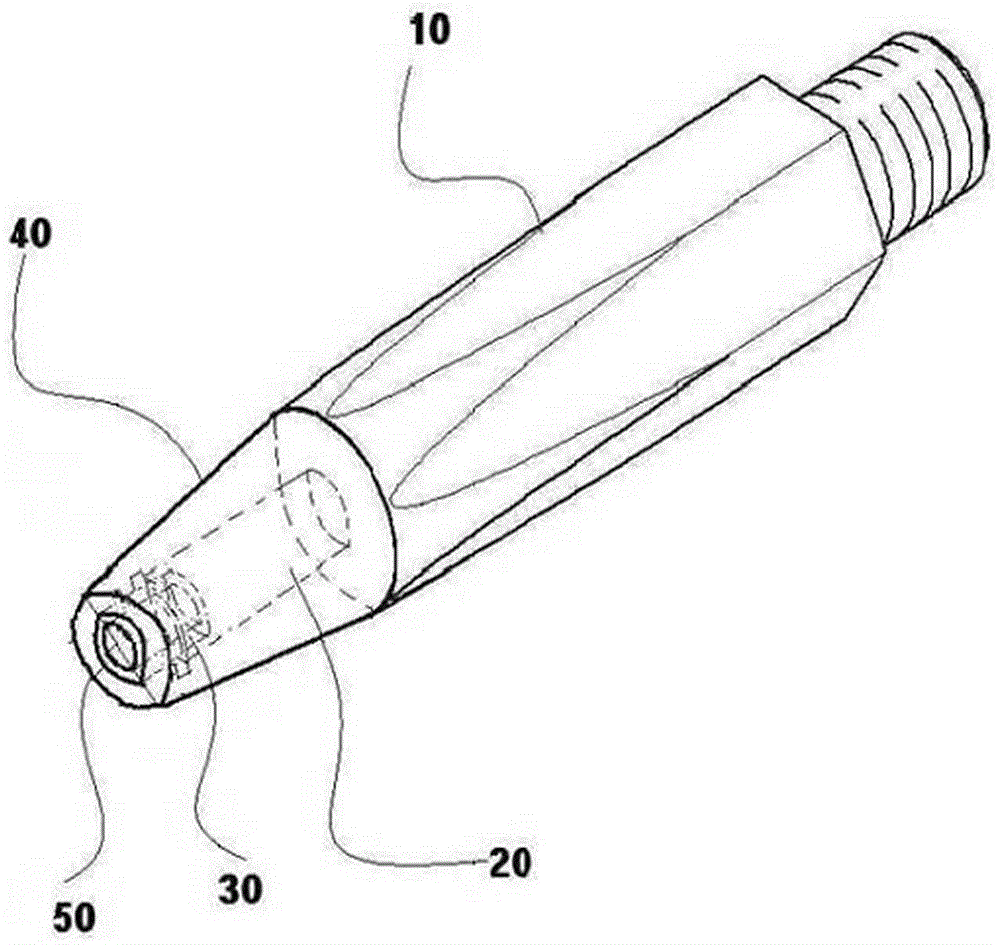

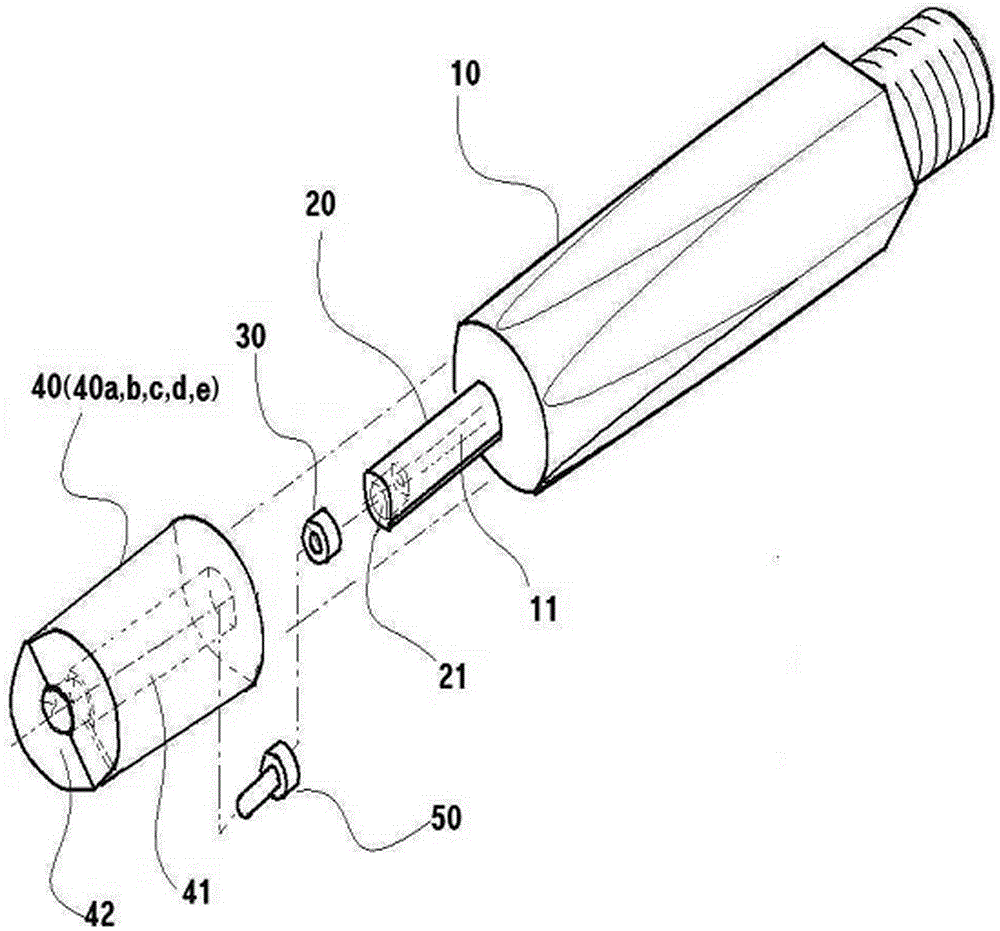

[0037] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the drawings.

[0038] Such as Figure 1 to Figure 3 As shown, the gas shielded welding contact tip equipped with a shaft sleeve of the present invention is a copper contact tip 4, which is installed on the receiving welding wire 3 at a predetermined speed and according to the contact tip generated between the welding wire 3 and the base material 2. The front end of the gas shielded welding welding machine 1 that forms the molten pool by welding the arc, and transmits the welding current to the welding wire 3 to guide the molten pool, including: a nozzle body 10 made of copper, which is drilled for installation on the welding machine 1 There is a through hole 11; a cylindrical rod-shaped electric connection part 20 is integrally connected to the front of the nozzle main body 10; a bushing 30 is installed on the front end of the electric connection part 20; a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com