End wall of railway wagon made by aluminum alloy and manufacturing method thereof utilizing friction stir welding

A technology of friction stir welding and friction stir, which is applied in the direction of railway car body, railway car body parts, funnel car, etc., to achieve the effect of small deformation of welding workpiece, simple equipment, stable and reliable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

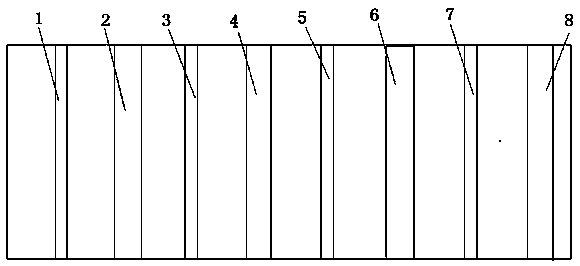

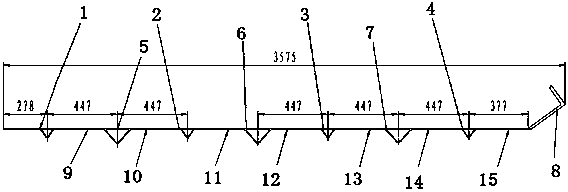

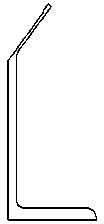

[0047] The aluminum alloy profile includes a "7"-shaped profile 1, a single-character plus small triangular rib profile 2, and a single-character enlarged triangular rib profile 3, wherein there is 1 "7"-shaped profile, and a single-character plus small triangular rib There are 4 pieces of strip profiles and 3 pieces of vertically enlarged triangular rib profiles, totaling 8 pieces.

[0048] The aluminum alloy profiles are arranged according to one piece of small triangular rib profiles 1, 2, 3 and 4, and one piece of one-word enlarged triangular rib profiles 5, 6 and 7, arranged in a cross, and the end is "7" shaped profile 8 The sequence combination selection is assembled together, and the combination is spliced and welded together to form an integral end wall.

[0049] The combined splicing welding is friction stir welding, the welding seam 9, 10, 11, 12, 13 and 14 of the one-word plus small triangular rib profile and the one-word enlarged triangular rib profile and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com