Tube welding and locating device for production

A positioning device and pipe fitting welding technology, which is applied in the field of pipe fitting processing, can solve the problems of no welding positioning of straight pipe fittings and bent pipe fittings, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

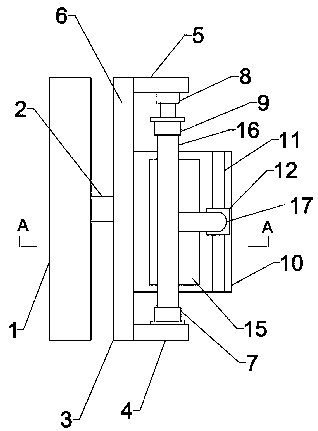

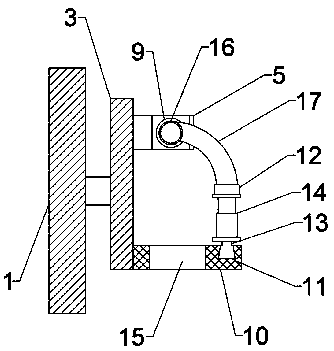

[0025] see Figure 1-Figure 4 , a pipe welding positioning device for production, including a base 1, a fixing frame 3, a support plate 10, a first pipe positioning part 7, a second pipe positioning part 9 and a third pipe positioning part 12; the fixing frame 3 includes The first fixed plate 4 and the second fixed plate 5 that are arranged in parallel are vertically fixedly connected with a connecting plate 6 between the first fixed plate 4 and the second fixed plate 5; one side of the connecting plate 6 is fixedly connected with the support plate 10, and the The other side of the plate 6 is rotatably connected to the base 1 through the rotating shaft 2; the inner side of the first fixing plate 4 is provided with a first pipe positioning part 7, and the first pipe positioning part 7 and the first fixing plate are detachably fixed by threads connection; the inside of the second fixing plate 5 is provided with a second pipe positioning part 9 driven by the lifting drive mechani...

Embodiment 2

[0030] The content of embodiment 2 is basically the same as that of embodiment 1, the difference is that: the support rod 14 is a telescopic rod, and the telescopic rod is an inner and outer sleeve structure, and the inner and outer sleeves are provided with matching inner and outer sleeves. , External thread.

[0031] The use method of the pipe fitting welding positioning device for production of the present invention is as follows:

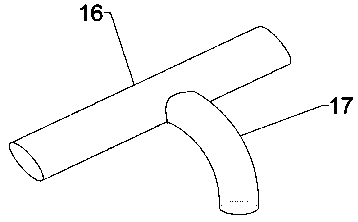

[0032] When welding the straight pipe 16 and the bent pipe 17 to each other, put one end of the straight pipe 16 to be welded in the first pipe positioning part 7, and then adjust the electric push rod according to the length of the straight pipe 16 to make the second pipe The positioning part 9 is sleeved on the other end of the straight pipe part 16 to realize the positioning of the straight pipe part 16; according to the welding position of the straight pipe part 16 and the bent pipe part 17 and the size of the bent pipe part 17, the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com