Railway aluminium alloy truck upper funnel ridge and friction stir welding production method

A friction stir welding and friction stir technology, which is used in railway car body parts, hopper cars, transport passenger cars, etc., to achieve the effects of small deformation of welding workpieces, simple equipment, and stable and reliable welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

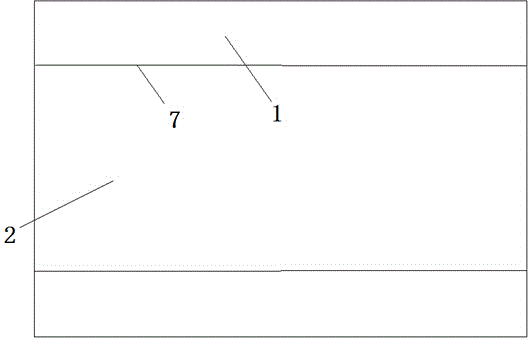

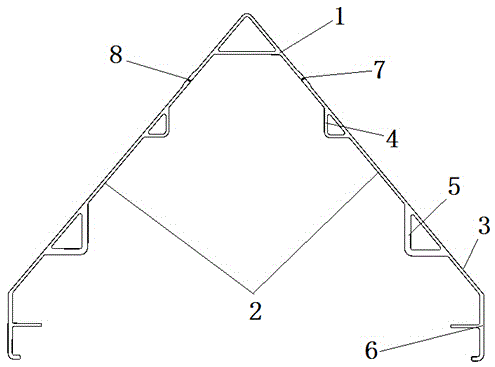

[0050] It can be seen from the accompanying drawings that the present invention relates to an upper funnel ridge of a railway aluminum alloy wagon. The upper funnel ridge is integrally formed by splicing aluminum alloy profiles; Friction welding welds the aluminum alloy profiles to each other to form the upper funnel ridge of the whole aluminum alloy.

[0051] The aluminum alloy profiles include "A"-shaped aluminum alloy profiles 1 and composite structure aluminum alloy profiles 2, wherein, there is 1 "A"-shaped aluminum alloy profile and 2 composite structure aluminum alloy profiles, totaling 3 pieces; The composite structure aluminum alloy profile 2 includes a straight side 3, and there are two triangular reinforcing ribs on the inner surface of the straight side 3, one is a small triangular rib 4, and the other is a large triangular rib 5; the lower end of the straight side 3 The head is vertically connected with an inverted "F" shaped profile 6.

[0052] The aluminum allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com