Anti-oxidation automatic welding method for process holes of titanium alloy pipelines in satellite propulsion system

A propulsion system, titanium alloy tube technology, applied in welding equipment, metal processing equipment, manufacturing tools and other directions, can solve the problems of long manual welding time, oxidation of the inner wall of the weld, unstable parameters, etc., to shorten the oxidation time of the weld, The time for oxidation of the weld is small, and the effect of avoiding contact tungsten inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

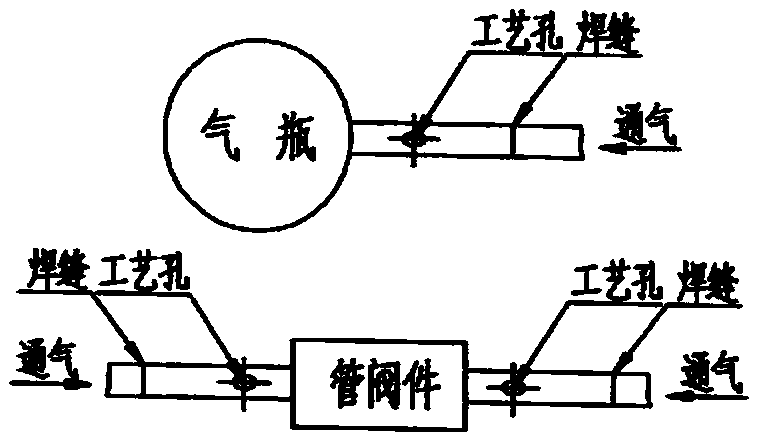

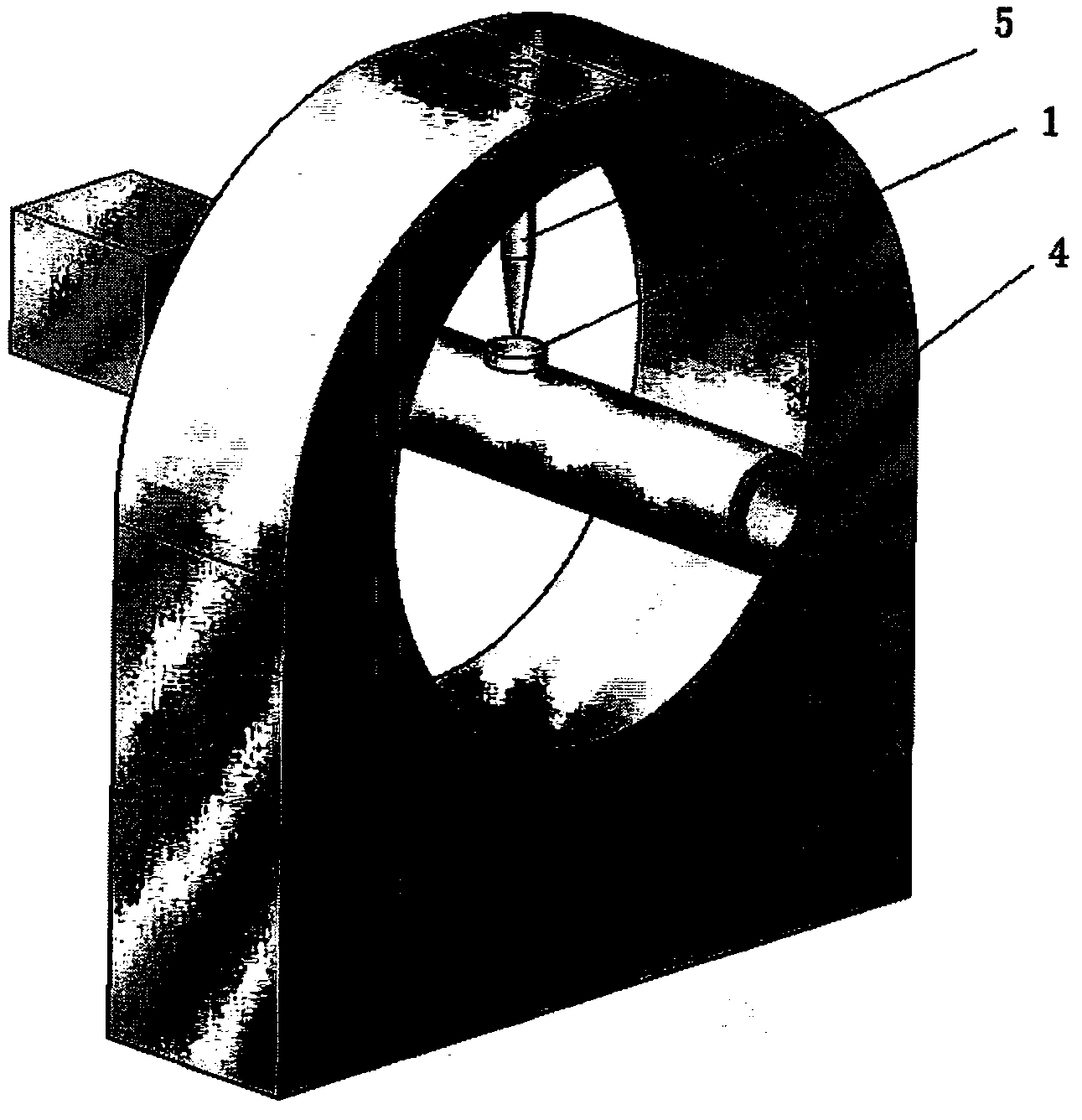

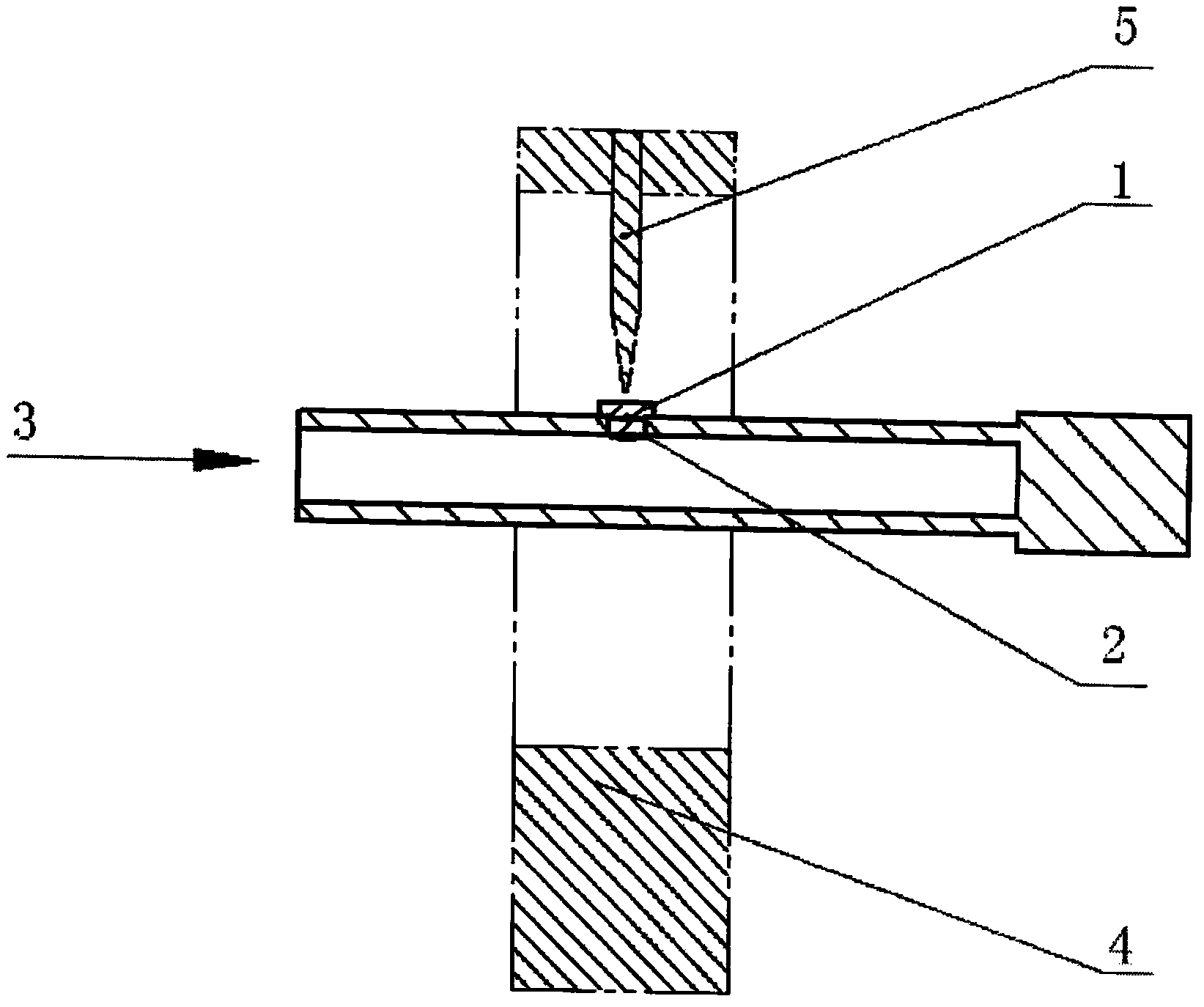

[0020] like figure 2 , 3 As shown, the method of the present invention adopts the process plug 1 that has small hole to be installed in the process hole 2, and the inside of the conduit passes a small amount of inert protective gas 3 through the small hole of the plug, and the tungsten pole 5 (welding electrode) is fixed by welding pipe clamp 4 Automatic welding is completed at the process hole 2.

[0021] figure 2 , 3 The tiny through hole in the center of the medium process plug 1 is determined according to the diameter of the process hole 2, and the general diameter is 0.5-0.8mm. The process plug 1 can be installed in any part of the pipeline process hole of any size product of the satellite propulsion system. The flow rate of the trace inert shielding gas is matched with the welding parameters to adjust and control according to the shape of the weld seam, so that the inner surface of the weld seam is bright and silvery white. The welded pipe clamp is an ultra-thin we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com