Sidewall plate of railway hopper wagon made by aluminum alloy and friction-stir welding method thereof

A technology of friction stir welding and friction stir, which is applied in the direction of funnel car, railway car body, railway car body parts, etc., to achieve the effect of stable structure, overall structure optimization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

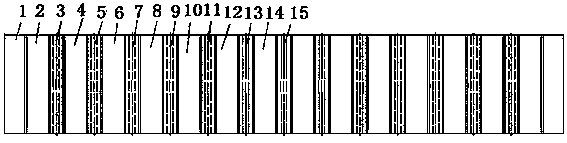

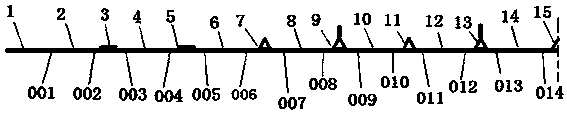

[0047] by attaching figure 1 and 2 It can be seen that the present invention relates to a side wall panel of a railway aluminum alloy funnel car. The side wall panel is formed by splicing aluminum alloy profiles as a whole; The aluminum alloy profiles are welded to each other to form a whole aluminum alloy side wall panel.

[0048] Further, the aluminum alloy profiles include 3 types of profiles, among which, there are 16 inline profiles, 4 profiles with "herringbone" shaped ribs in the middle of a character, 5 profiles with triangular ribs in the middle of a character, and There are 4 profiles with bosses in the middle, a total of 29 pieces. Arrange the above profiles in order and weld them together by friction stir welding to form a whole piece of aluminum alloy side wall panel to form a whole piece of aluminum alloy side wall panel to form a whole piece of aluminum alloy side wall panel wall panels.

[0049] Further, the aluminum alloy profiles are arranged in a symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com