Positioning and clamping device for butt welding of mixer head group and its operation method

A technology for positioning, clamping and operating methods, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of uniformity, low position accuracy, low degree of automation, low processing efficiency, etc., and achieve low labor intensity for workers. , good versatility, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

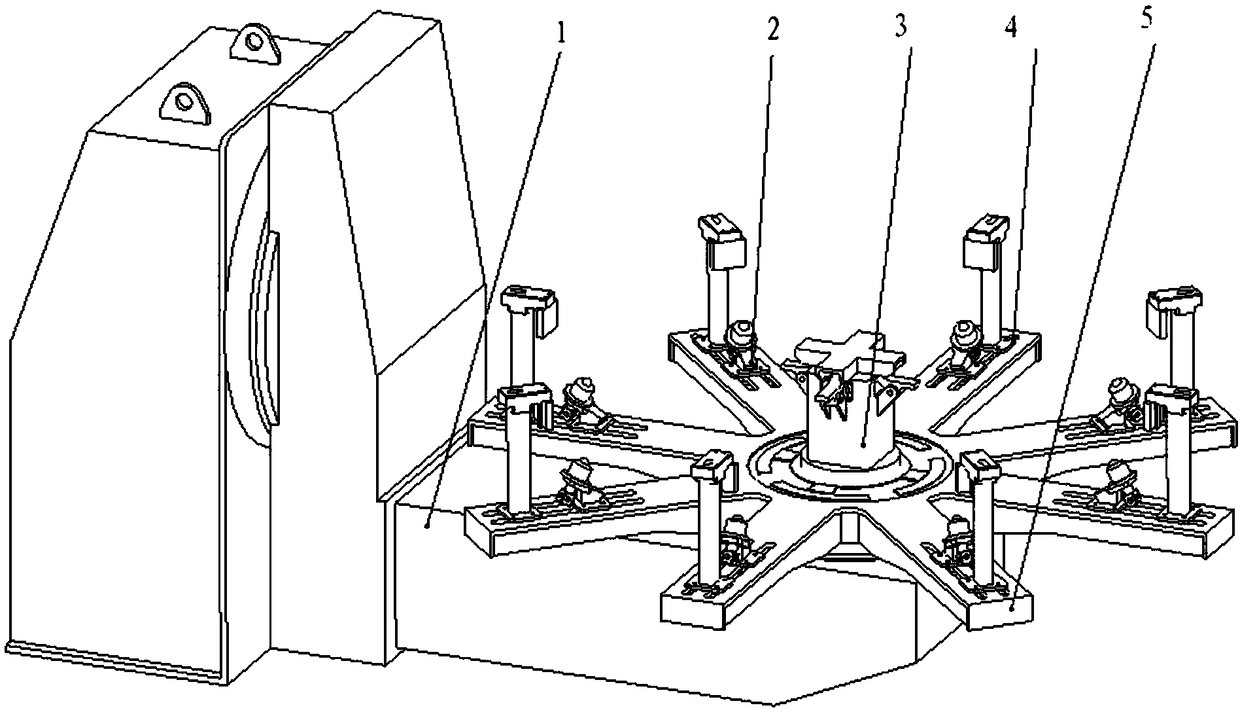

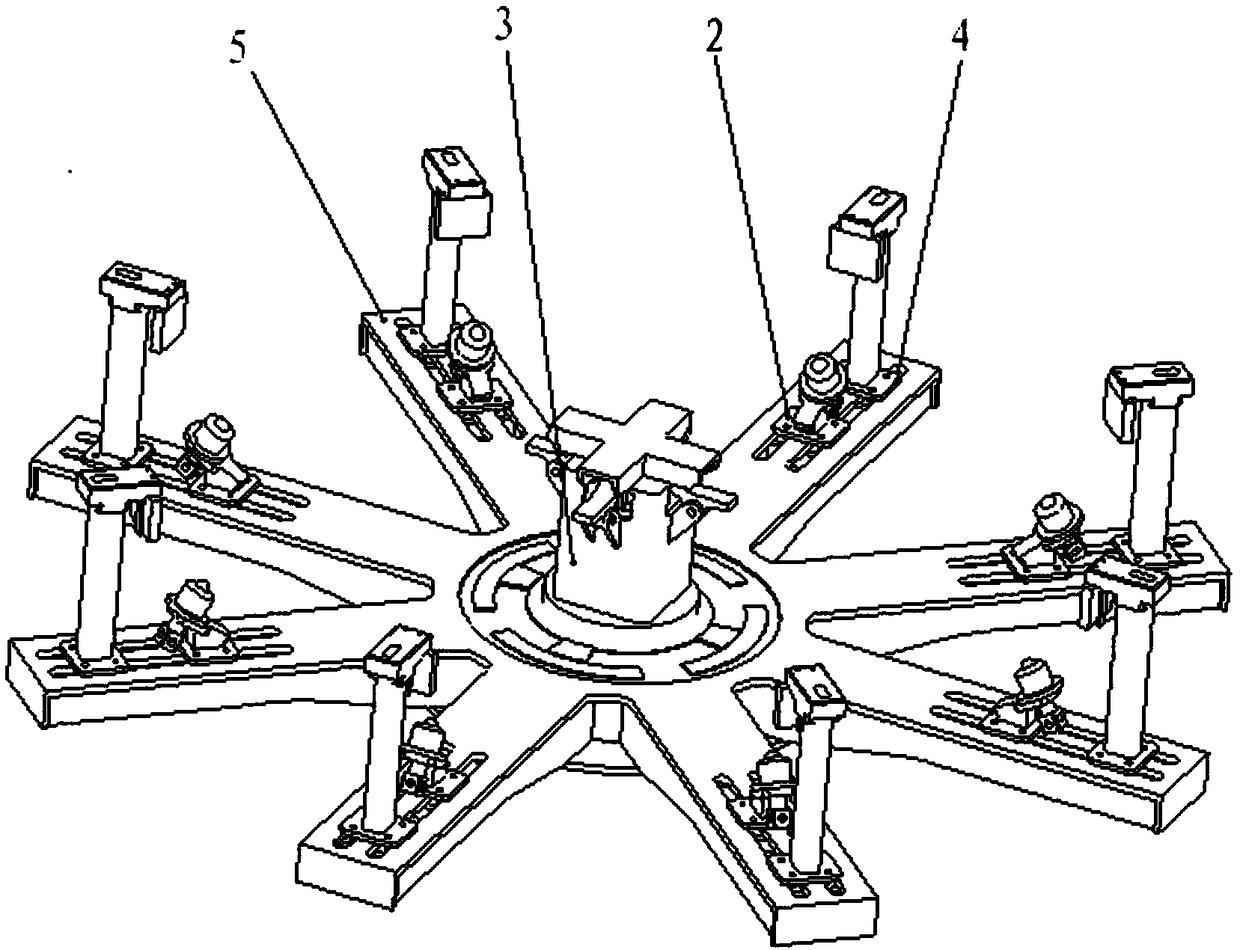

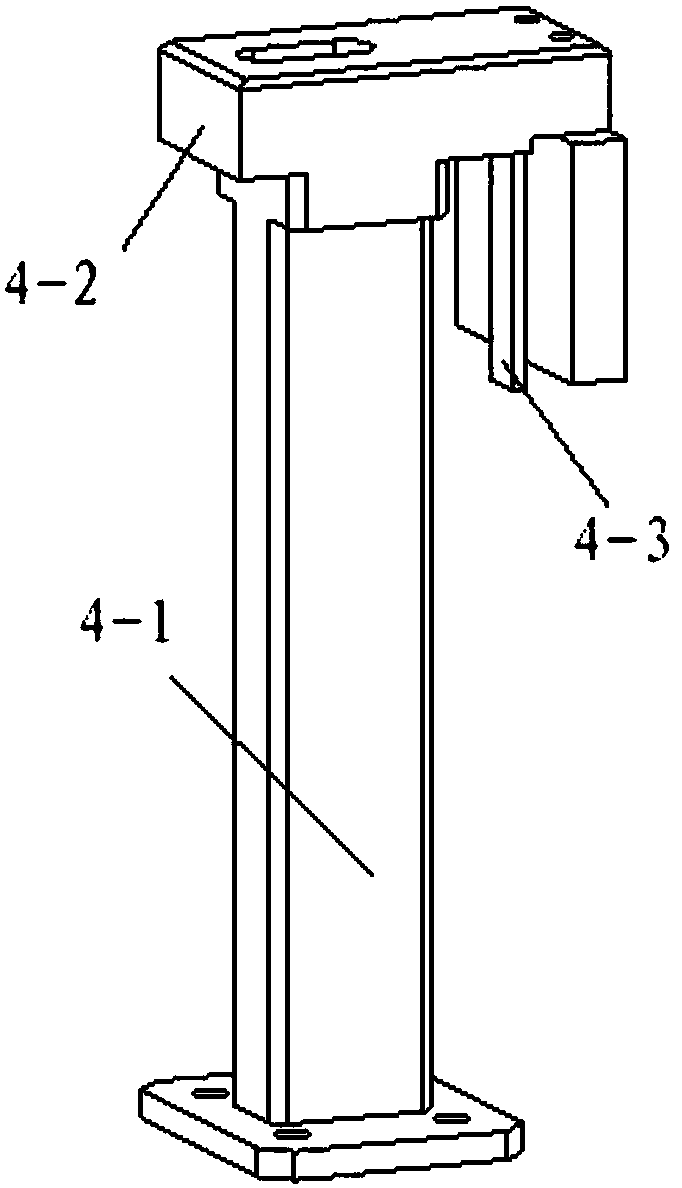

[0030] From figure 2 It can be seen that the positioning and clamping device for butt welding of the head group of the mixer truck in the present invention is characterized in that it includes a ball support 2, a pneumatic compression device 3, a briquetting block 4, and an upper platform 5; a ball support 2 and a pneumatic compression device Both the device 3 and the pressing block 4 are arranged on the upper platform 5 . Among them, the pneumatic clamping device is specially used to compress the flange so that it does not leave its position during the rotary displacement. At the same time, the automatic pneumatic clamping device completes the flange clamping with one key, which is simple and fast. The structure of the pneumatic clamping device is as follows: Figure 5 as shown,

Embodiment 2

[0032] From figure 1 , figure 2 , Figure 6 It can be seen that the upper platform 5 in the above embodiment is spoke-shaped, with a circular platform in the middle, and there are several cantilevers uniformly distributed along the circumferential direction radiating outward from the outer circle of the circular platform, and each cantilever is provided with a press Block 4, a ball head support 2; the pneumatic pressing device 3 is arranged in the middle of the circular platform at the center of the upper platform 5 .

Embodiment 3

[0034] In the above-described embodiment, each cantilever of the upper platform 5 has two parallel racetrack-shaped through holes as tracks, and the briquetting block 4 and the ball support 2 are connected with the cantilever through the racetrack-shaped through-holes, and the briquetting block 4 is positioned on the ball. The outside of the head support 2. In this way, whether there is a processing tolerance in the parts of the same type of head, or different types of heads with little difference in size, the ball support 2 and the pressing block 4 can be moved and adjusted in the raceway-shaped through hole to realize positioning and clamping. It is tight, thereby improving its versatility, further improving work efficiency, and reducing the workload of workers, saving time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com