Connection method for crimping-to-welding circuit board, and connecting terminal

A connection terminal and connection method technology, applied in the field of methods and connection terminals, to achieve reliable solder joints, reduce the possibility of solder fatigue or even fracture, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

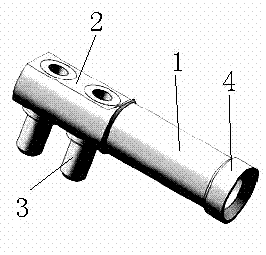

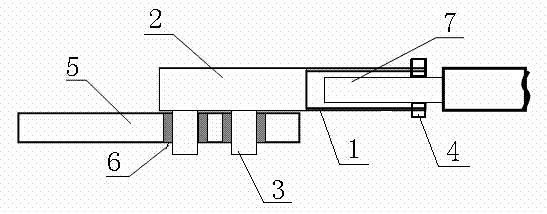

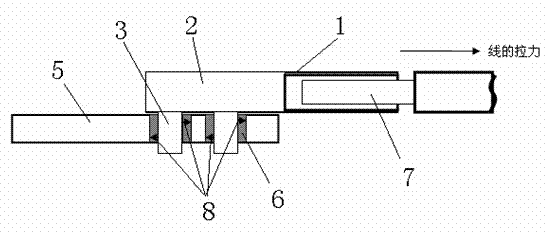

[0033] The connection edge 4 at the pier hole 4 is connected to the connection line with pressing needle clamping; the welding needle 3 is the raised of the two that can be adapted from the connected terminal body.The connection hole 6 of the board pad 5; by describing the welding needle 3 and the circuit board pad welded, connect the connected terminal body 2 with the circuit board pads 5 tightly;, Connecting terminal and circuit board welding rotor -welded circuit board wiring terminal structure.

[0034] The welded circuit board wiring terminal is described, figure 1 The welding needle is connected to the wiring terminal through the pressure rivet, and the direction of the circuit direction and the pad connection holes is achieved by 90 degrees.

[0035] The welded terminal wiring terminal of a voltage rotation welded circuit board is generally used as a substrate. According to the actual conductive demand and facilitated welding, the surface can be plated, silver plated, or ti...

Embodiment 2

[0040] The welded circuit board wiring terminal of a voltage rotation is used, which uses brass as a substrate, with gold plating, silver plating or tin -plated.

[0041] Example II

Embodiment 3

[0043] The welded circuit board wiring terminal of a voltage rotation is used, which uses copper as a substrate, with gold plating, silver plating or tin -plated.

[0044] It can be seen from the above embodiment that the present invention involves a rotating welded circuit board connection method. Add a pressure rotation welding device between the circuit board pad that needs to be connected and the connection cable.The device is connected with the circuit board pad; where the connection between the connection line and the pressure rotation welding device is connected by a pressure connection method, and the connection between the pressure connection welding device and the circuit board pad is connected by welding.The most reliable pressure connection method is used, and the connection with the circuit board is the most simple and convenient welding method.Avoid when the connection line and the circuit board are welded directly (especially when the wires are relatively thick), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com