Low-frequency and low-power laser welding method for oxygen-free copper

A technology of laser welding and oxygen-free copper, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of graphite coating affecting welding strength, uneven coating of graphite coating, etc., and achieve smooth weld joints Good looking and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

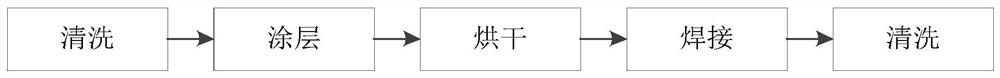

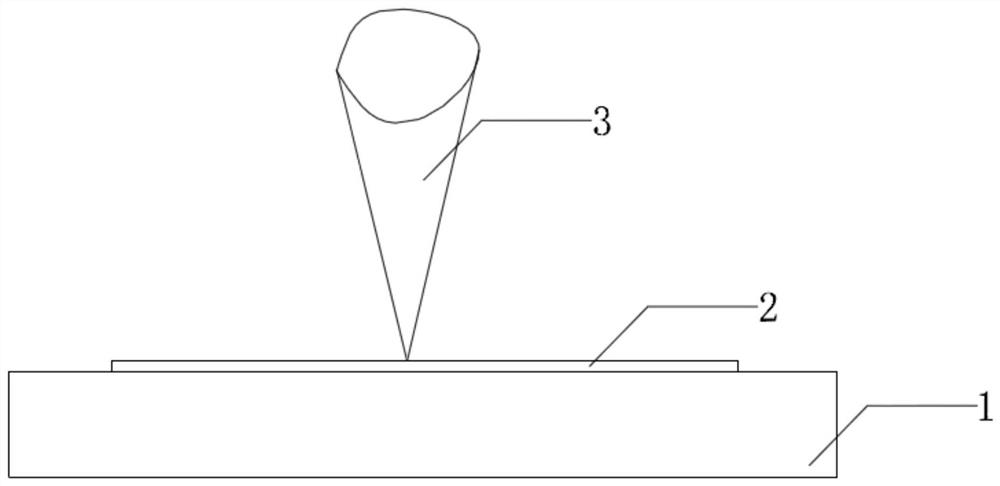

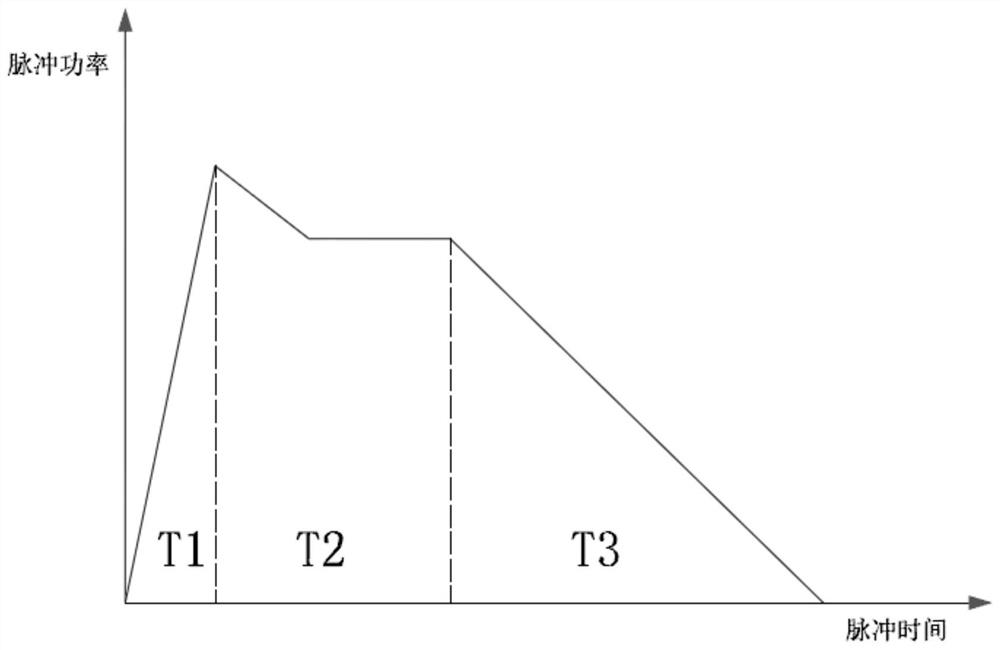

[0019]In order to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments. The size of the oxygen-free copper cavity in this embodiment is 21mm×20mm×4mm, and the cover thickness is 0.5mm. The laser welding equipment preferably has a power of 300W and a frequency of 10Hz, and the sealing and welding meets the requirements of GJB air tightness.

[0020]Before coating the light-absorbing layer material at the welding seam of the oxygen-free copper cavity, use n-bromopropane and anhydrous ethanol to wipe the welded area in order to remove oxides, organics, pollutants, etc. indicated by oxygen-free copper;

[0021]When coating the light-absorbing layer material on the welding seam of the oxygen-free copper cavity, use a brush to uniformly coat the light-absorbing layer material on the portion to be welded of the oxygen-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com