MIG+TIG double-faced welding method for butt joint of stainless steel composite tube or composite plate

A double-sided welding and stainless steel technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor corrosion resistance of the clad stainless steel side and achieve high welding efficiency, good comprehensive mechanical properties, and excellent welding methods Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Such as figure 1 As shown, a preferred embodiment of the present invention provides a method for butt joint MIG+TIG double-sided welding of stainless steel composite pipe or composite plate, comprising the following steps:

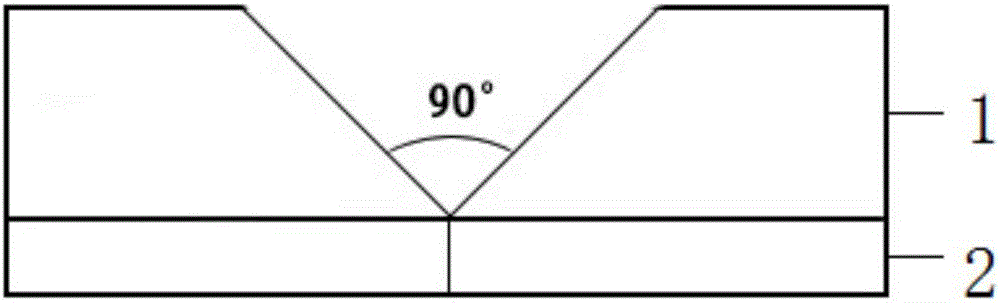

[0028] Step 1, the base layer 1 is provided with a bevel cut, and the stainless steel cladding layer 2 is provided to maintain the original thickness;

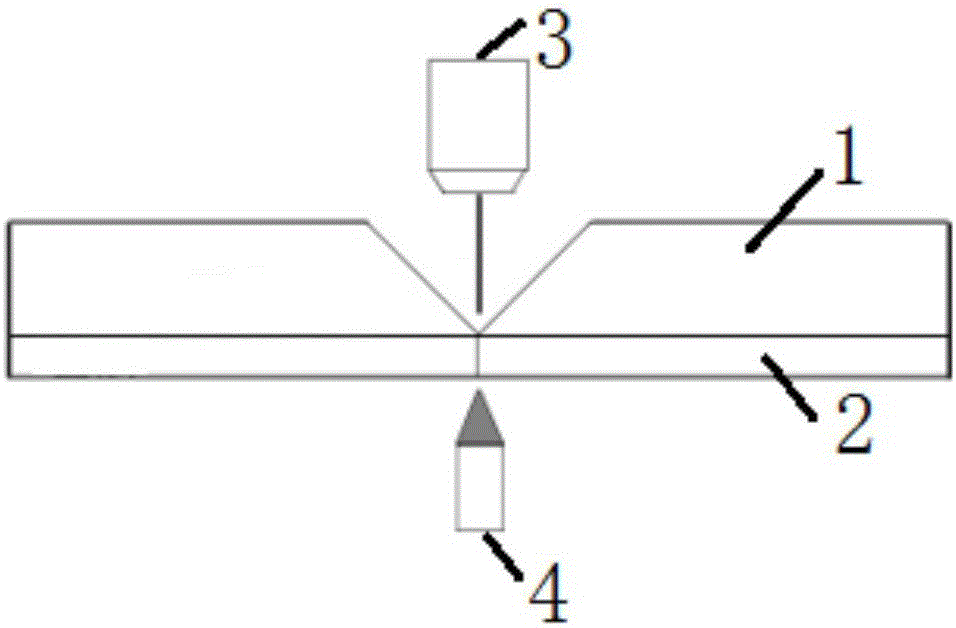

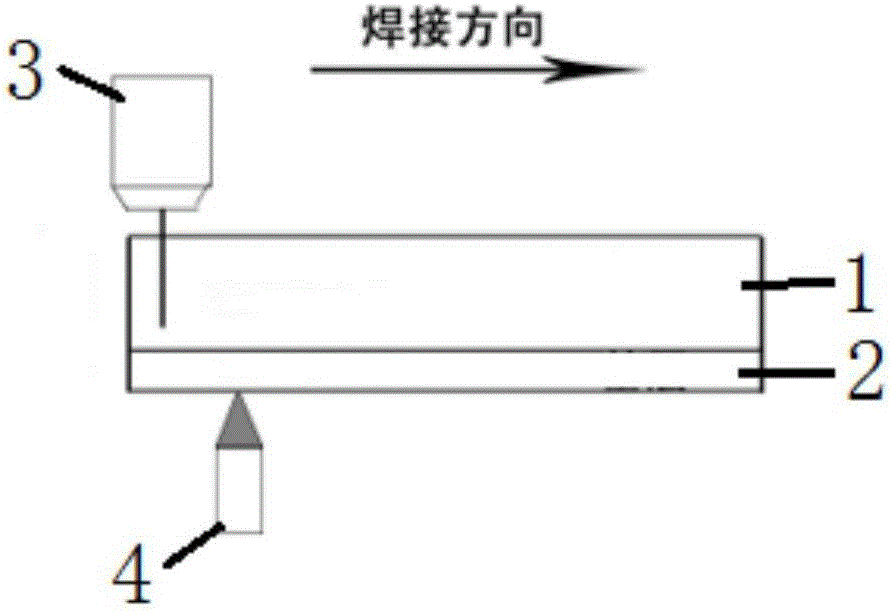

[0029] Step 2. Use MIG welding torch 3 to weld the base layer 1, and use TIG welding torch 4 to weld the stainless steel clad layer 2. MIG welding torch 3 and TIG welding torch 4 are welded in the same direction, and the TIG welding torch starts welding before the MIG welding torch.

[0030] Such as figure 1 As shown, the stainless steel clad plate needs to be processed before welding, and the base layer 1 is processed into an inclined cut, while the original thickness of the stainless steel clad layer 2 is retained. Wherein, the base layer is carbon steel or low alloy steel.

[0031] The stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com