Steel-stainless steel mining gas drainage pipe exploding welding device and welding method

An explosive welding and gas extraction technology, which is applied in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve problems such as poor universality of restrained pipe molds, shortening the service life of pipe molds, and increasing the use cost of pipe molds. , to avoid deformation, reduce the construction site area, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

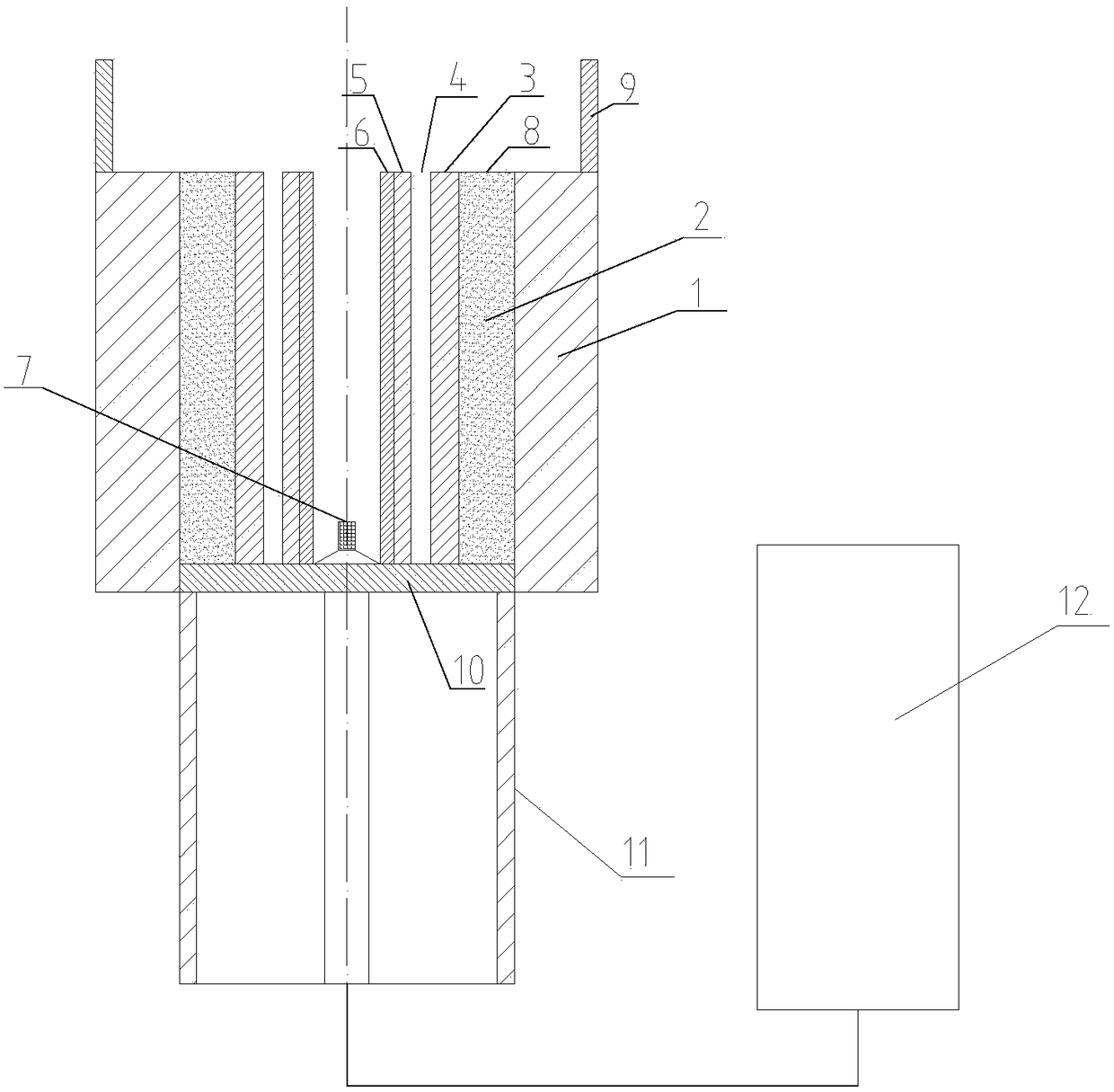

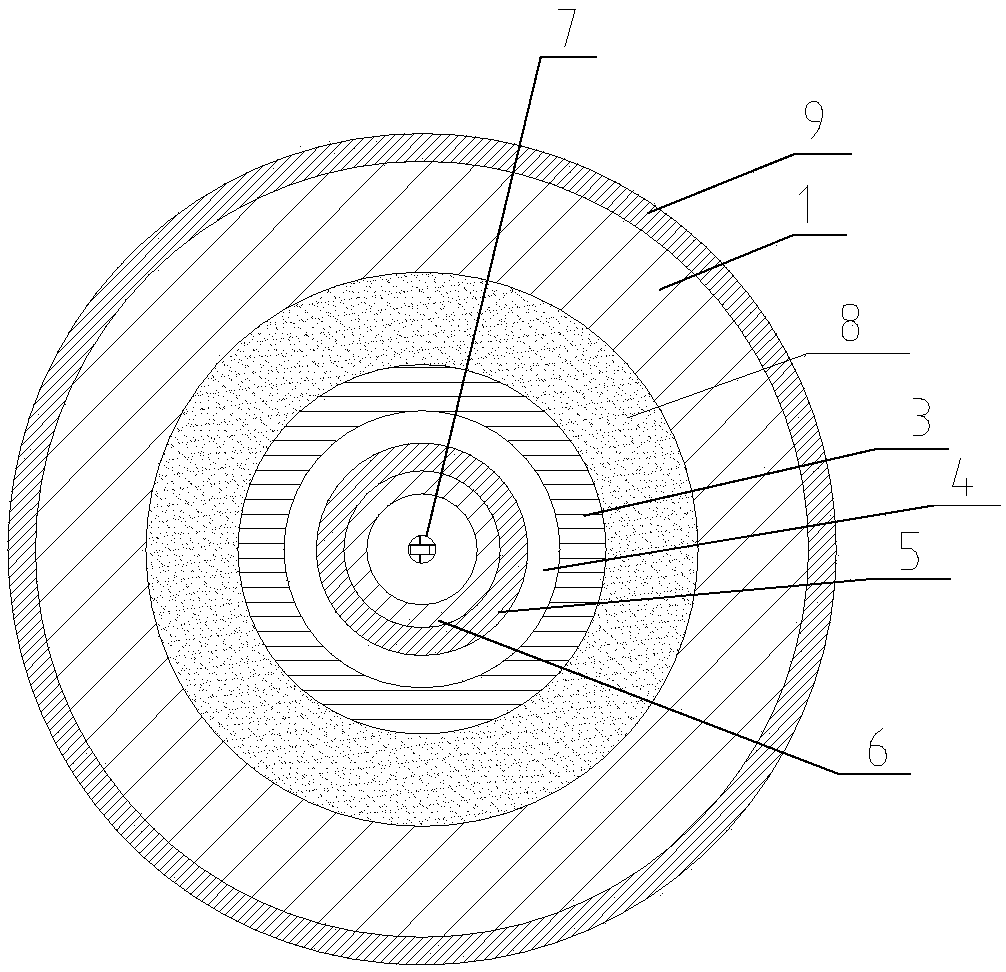

[0037] like figure 1 , 2As shown: the steel-stainless steel mine gas drainage pipe explosive welding device of the present invention is characterized in that it includes a stainless steel inner multiple pipe 5 arranged vertically and coaxially from the inside to the outside, a steel base pipe 3, and a restraint pipe mold 1. An explosive layer 6 is evenly arranged on the inner surface of the stainless steel inner composite pipe 5, an air layer 4 is formed between the stainless steel inner composite pipe 5 and the steel base pipe 3, and the steel base pipe 3, the restraint pipe mold 1 is filled with a constrained layer 2 made of liquid or solid granular material.

[0038] The restraining mechanism for preventing deformation of the steel base pipe 3 of the present invention is composed of the restraint layer 2 and the restraint pipe mold 1. Since the rest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com