Method for welding and repairing copper surface defect of aluminum-copper composite board transition joint

A transition joint and welding repair technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increasing production cost and reducing production efficiency, and achieve the effects of reducing labor intensity, improving thermal effect, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

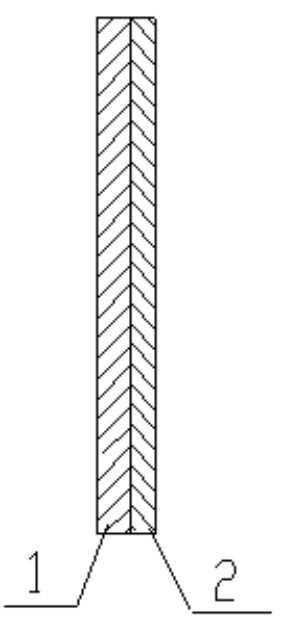

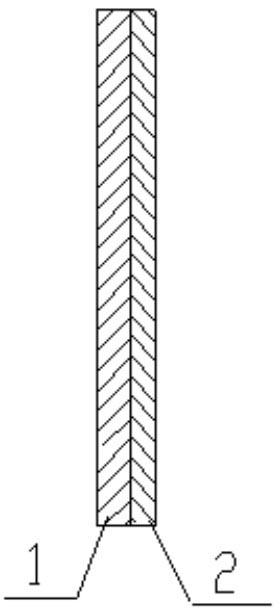

[0022] Such as figure 1 with figure 2 As shown, an aluminum-copper composite plate transition joint is prepared by explosive welding of copper plate and aluminum plate. The thickness of copper plate and aluminum plate is 15mm and 12mm respectively, and the depth of the pit on the copper surface of aluminum-copper cross-composite plate transition joint is 4.0mm. , first clean up the impurities in the area to be welded in the pits on the copper surface of the aluminum-copper cross-composite joint, preheat the welding start position of the area to be welded to 185°C, and start welding when the welding wire is made of the same material as the base metal (copper). Welding wire HSCu, the diameter of the welding wire is 1.0mm. During welding, tap water is introduced on the aluminum surface of the aluminum-copper composite plate transition joint for cooling. When the temperature of the copper surface welding area of the aluminum-copper composite plate transition joint reaches 296 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com