Inner pipe shallow hole welding assembly device of jacket heat exchanger jacketed pipe, jacket heat exchanger and welding method of jacketed pipe

A heat exchanger and jacketed tube technology, which is used in indirect heat exchangers, heat exchanger types, fixed tubular conduit components, etc. Welding, influence and other problems, to achieve the effect of simple structure, control group to concentricity, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

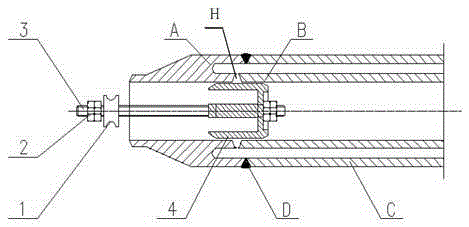

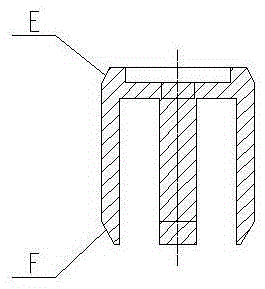

[0036]The inner tube shallow hole welding assembly of the jacketed tube of the jacketed heat exchanger of the present invention is used for the seamless connection between the inner tube B of the jacketed tube of the jacketed heat exchanger and the connecting groove of the end connector A Gap pair, the pair includes a claw locator 4, a rotating pull rod 3, a lock nut 2 and a knocking handle 1, one end of the rotating pull rod 3 passes through the central axis of the claw locator 4, and Fixedly connected by bolts and nuts, the other end of the rotating pull rod 3 is provided with the knocking handle 1 , and the knocking handle 1 is limited by the locking nut 2 . The claw-type positioner 4 of the coupler and the rotating rod 3 are connected by bolts and nuts, so that the coupler is a detachable movable device that does not need to be fixed on the equipment. It is easy to assemble and disassemble, simple and convenient, and has no need for equipment manufacturing. Adverse effects...

Embodiment 2

[0045] The jacketed heat exchanger of the present invention includes a jacketed tube composed of an inner tube B and an outer tube C, and end connectors A located at both ends of the jacketed tube, wherein the inner tube of the jacketed tube The connection groove between the pipe B and its end connector A is connected by butt welding of the inner pipe shallow hole welding group to the device group of the jacketed pipe of the jacketed heat exchanger described above. The welding quality of the jacketed heat exchanger is good, and the service life is prolonged.

Embodiment 3

[0047] The welding method of the jacketed tube of the jacketed heat exchanger and the end connector of the present invention includes step 1, after the inner tube B and the outer tube C are put through the tube, the welding seam of the end connector A and the outer tube C is first welded D; Step 2, after the welding seam D of the above-mentioned end connector A and the outer pipe C is welded, the pair welding of the weld H between the inner pipe B and the connection groove of the end connector A is carried out. The welding seam H is after the inner pipe B and the outer pipe C pass through the pipe, and the welding seam D of the end connector A and the outer pipe C is welded, and then the welding seam H is pair-welded, which belongs to the closed welding seam in the casing. Therefore, the weld seam H cannot be directly seen from the outside, and can only be assembled from the inside of the pipe. Put the claw locator 4 on the rotating pull rod 3, the lock nut 2 and the knocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com