Impeller for centrifugal pump

A technology for centrifugal pumps and impellers, which is applied to parts, pumps, and pump elements of pumping devices for elastic fluids, and can solve the problems of impellers being easily worn and stuck and manufacturing costs, and reduce processing difficulty and cost. , Guarantee wear resistance and reduce the effect of axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the description.

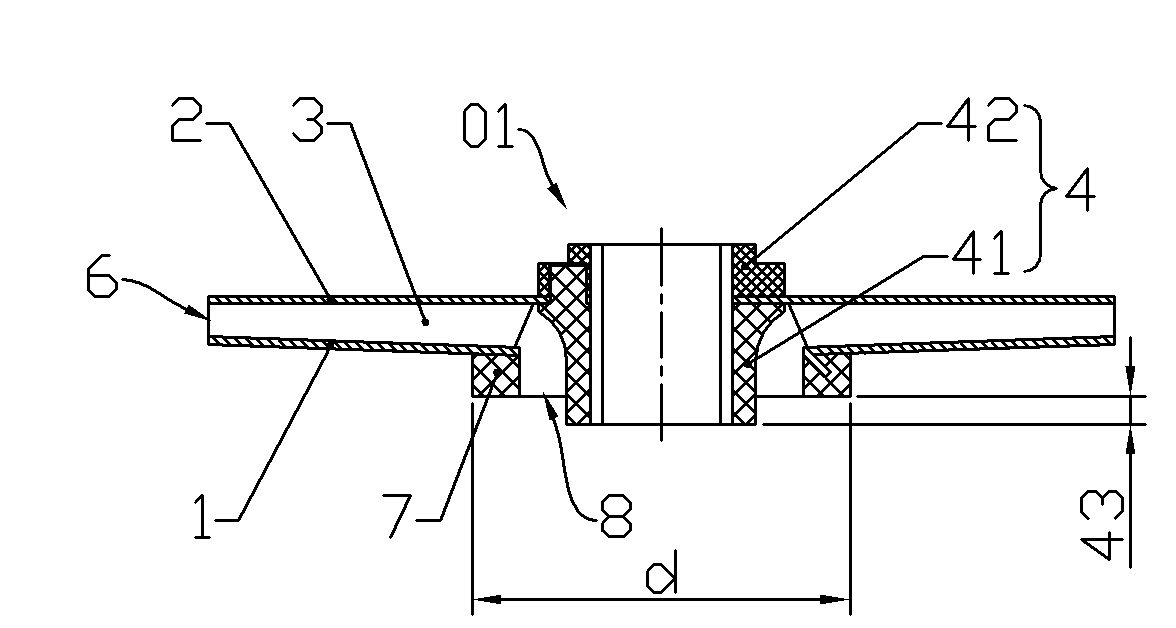

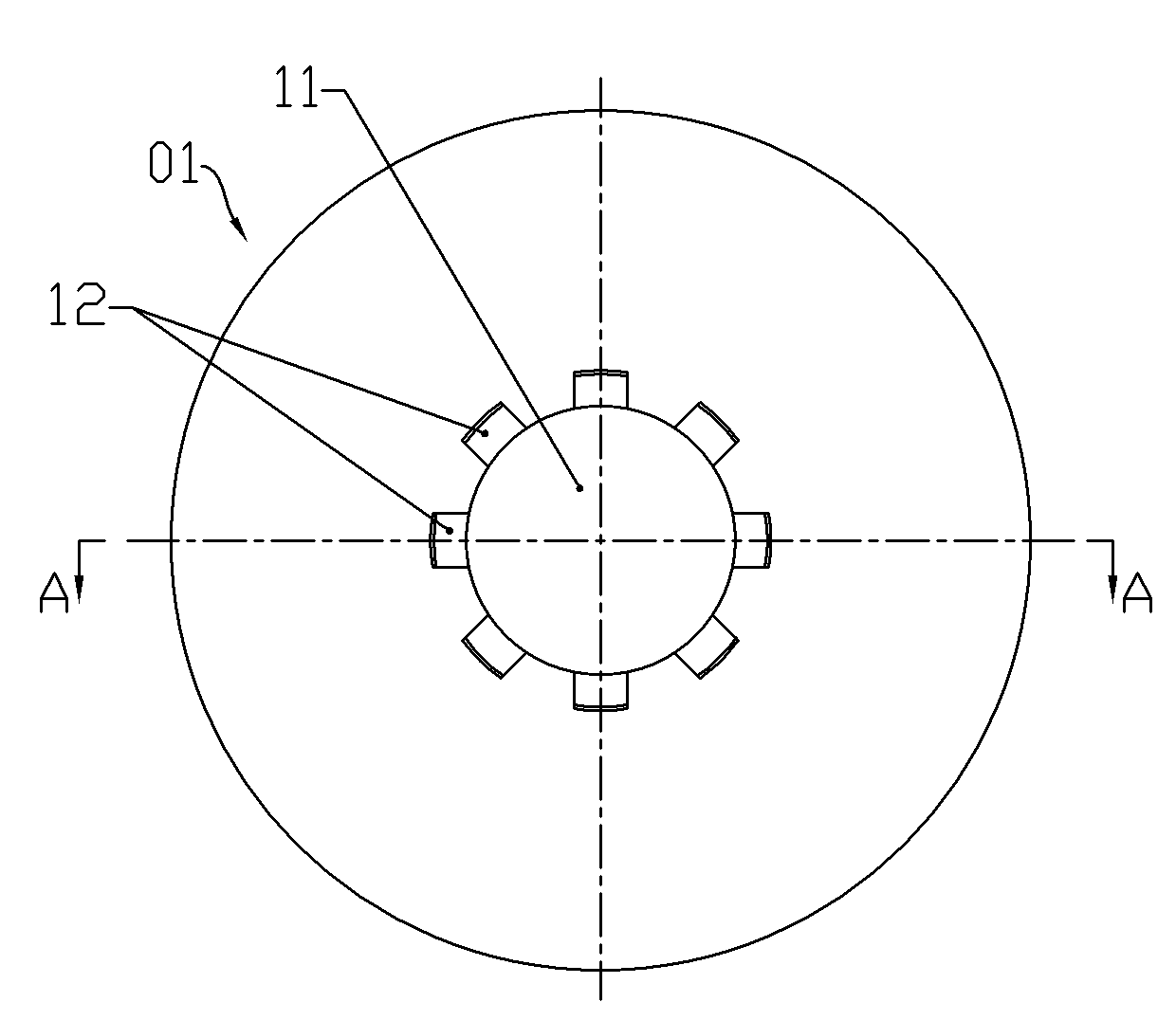

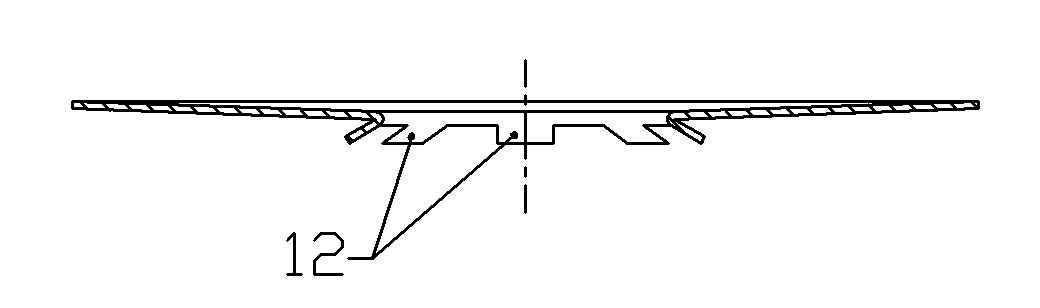

[0033] The impeller 01 for the centrifugal pump of the present invention, such as figure 1 As shown, it includes a front cover 1, a rear cover 2, a plurality of blades 3, and a hub 4. The front cover 1 and the rear cover 2 are circular and have through holes 11, 21 at the centers of the two, and the blades 3 It is in the shape of a curved plate, the front cover 1, the rear cover 2, and the blades 3 are made of stainless steel and the blades are distributed radially (see Figure 12 ) between the front cover 1 and the rear cover 2, the edge of the blade 3 is welded (such as by butt welding) with the front cover 1 and the rear cover 2, and the centrifugal channel 5 is formed between adjacent blades and The outer end of the centrifugal passage forms the impeller outlet 6, and the edge of the through hole 11 of the front cover plate 1 is shaped on a plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com