Metal bar fast-diffusion welding method based on pulse current treatment

A metal bar, pulse current technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to avoid extrusion deformation, reduce service life, save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

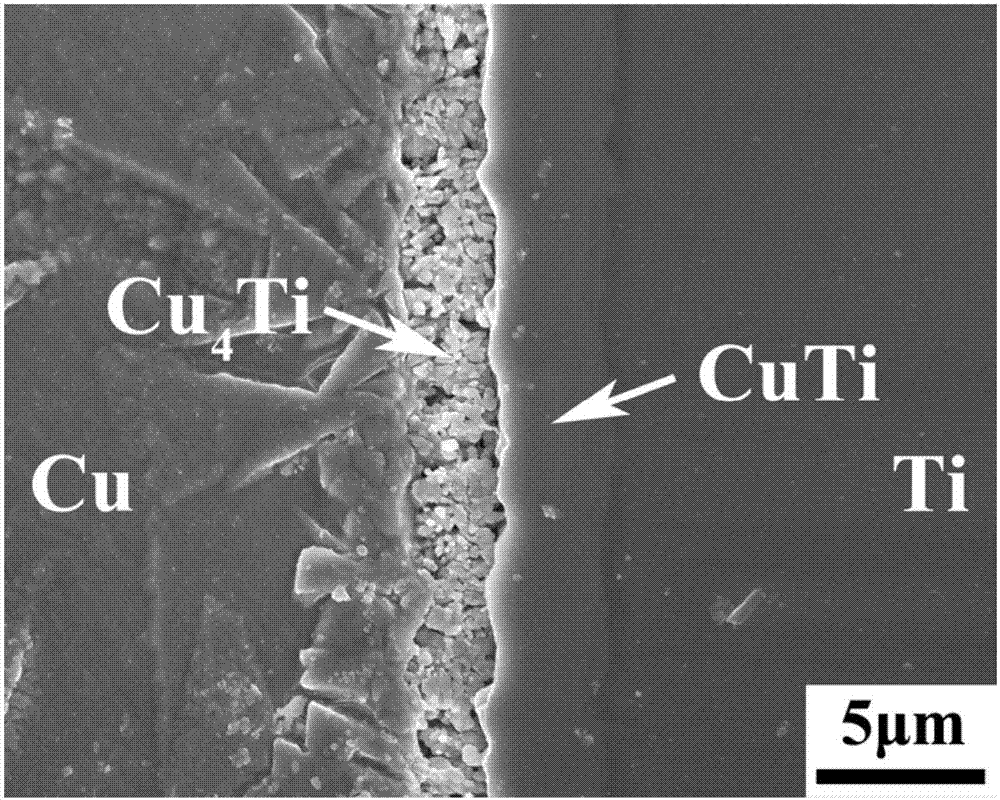

Embodiment 1

[0029] (1) Rod preparation: Industrial pure titanium TA1 and red copper T1 were hot-rolled at 800°C and 750°C, respectively, so that the diameter of the two bars was 15mm. To release the stress, the rolled industrial pure titanium TA1 and red copper T1 were respectively Annealing is carried out in a vacuum environment at a temperature of 680°Ch and 550°C for 2 hours, so that the average grain sizes of industrially pure titanium TA1 and copper T1 are 20 μm and 50 μm, respectively, and are cut by wire cutting to make the two rods The length of the material is 15mm. Subsequently, the two ends of the bar are polished with 360#, 600#, 800#, 1000#, 1500#, 2000# sandpaper, polished with 1.5μm, 1.0μm, 0.5μm diamond polishing agent, and finally soaked in acetone for ultrasonic cleaning For 20 minutes, ensure that the surface of the bar is clean and has a metallic luster, and ensure that the roughness of the end surface of the bar is less than 0.5 μm.

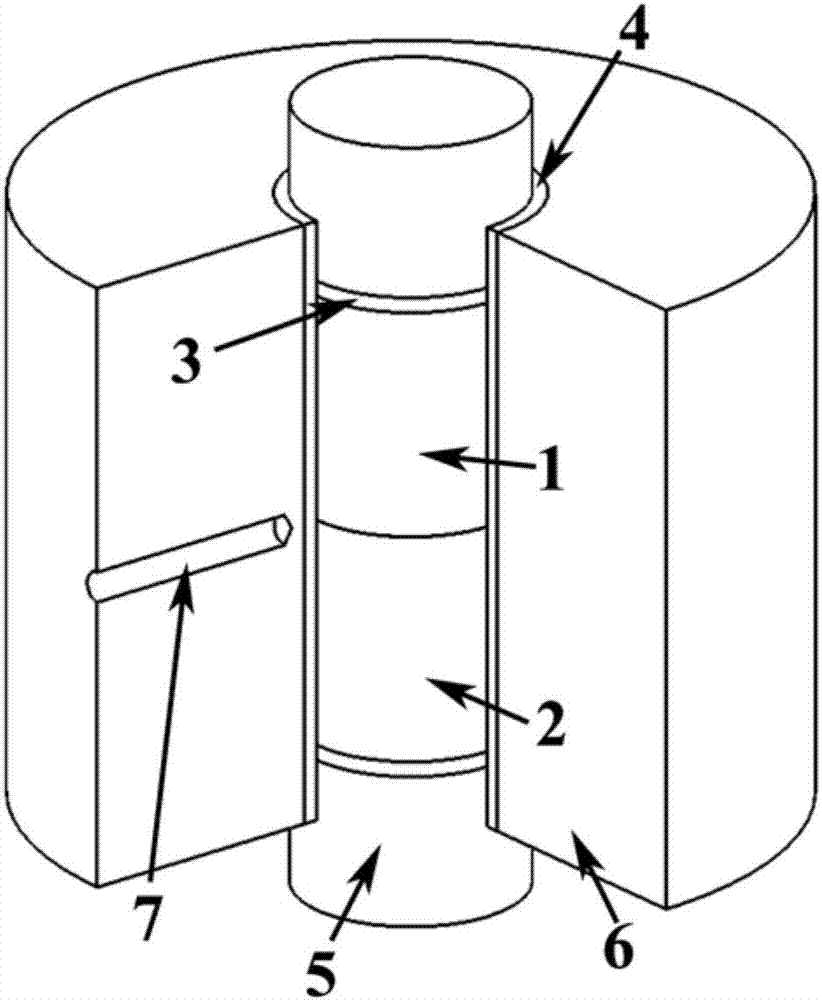

[0030] (2) Assembly: such as fi...

Embodiment 2

[0034] (1) Rod preparation: Industrial pure titanium TA1 and red copper T1 were hot-rolled at 800°C and 750°C, respectively, so that the diameter of the two bars was 15mm. To release the stress, the rolled industrial pure titanium TA1 and red copper T1 were respectively Annealing is carried out in a vacuum environment at a temperature of 680°Ch and 550°C for 2 hours, so that the average grain sizes of industrially pure titanium TA1 and copper T1 are 20 μm and 50 μm, respectively, and are cut by wire cutting to make the two rods The length of the bar is 15mm; then, the two ends of the bar are polished with 360#, 600#, 800#, 1000#, 1500#, 2000# sandpaper, and polished with 1.5μm, 1.0μm, 0.5μm diamond polishing agent, Finally, soak in acetone and ultrasonically clean for 20 minutes to ensure that the surface of the bar is clean and has a metallic luster, and that the roughness of the end surface of the bar is less than 0.5 μm.

[0035] (2) Assembly: such as figure 1 shown. One ...

Embodiment 3

[0039] (1) Rod preparation: Industrial pure titanium TA1 and red copper T1 were hot-rolled at 800°C and 700°C, respectively, so that the diameters of the two bars were both 15mm. In order to release stress, the rolled industrial pure titanium TA1 and red copper T1 were respectively Annealing was carried out in a vacuum environment at a temperature of 650°C and 600°C for 1.8 hours, so that the average grain sizes of industrially pure titanium TA1 and copper T1 were 18 μm and 50 μm, respectively, and were cut by wire cutting to make the two rods The length is 15mm; then, the two ends of the bar are polished with 360#, 600#, 800#, 1000#, 1500#, 2000# sandpaper, and polished with 1.5μm, 1.0μm, 0.5μm diamond polishing agent, and finally Perform acetone immersion ultrasonic cleaning for 18 minutes to ensure that the surface of the bar is clean and has a metallic luster, and the roughness of the end surface of the bar is ensured to be less than 0.5 μm.

[0040] (2) Assembly: such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com