Preparation method for powder metallurgy rotating hub gear

A powder metallurgy and gear technology, which is applied in the field of powder metallurgy hub gear preparation, can solve the problems of low elongation of powder metallurgy materials, inability to complete the welding process, reduced welding strength, etc., and achieves a simple preparation method and a firm structure of the hub gear. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the powder metallurgy hub gear in this embodiment is characterized in that it includes the following steps:

[0037] (1) Design material composition

[0038] In terms of mass percentage, the material used for the hub gear base includes the following components: 5% copper, 2% unavoidable impurity elements, and the balance is iron;

[0039] In terms of mass percentage, the material used for the hub gear shaft includes the following components: 5% copper, 2% or less unavoidable impurity elements, and the balance is iron;

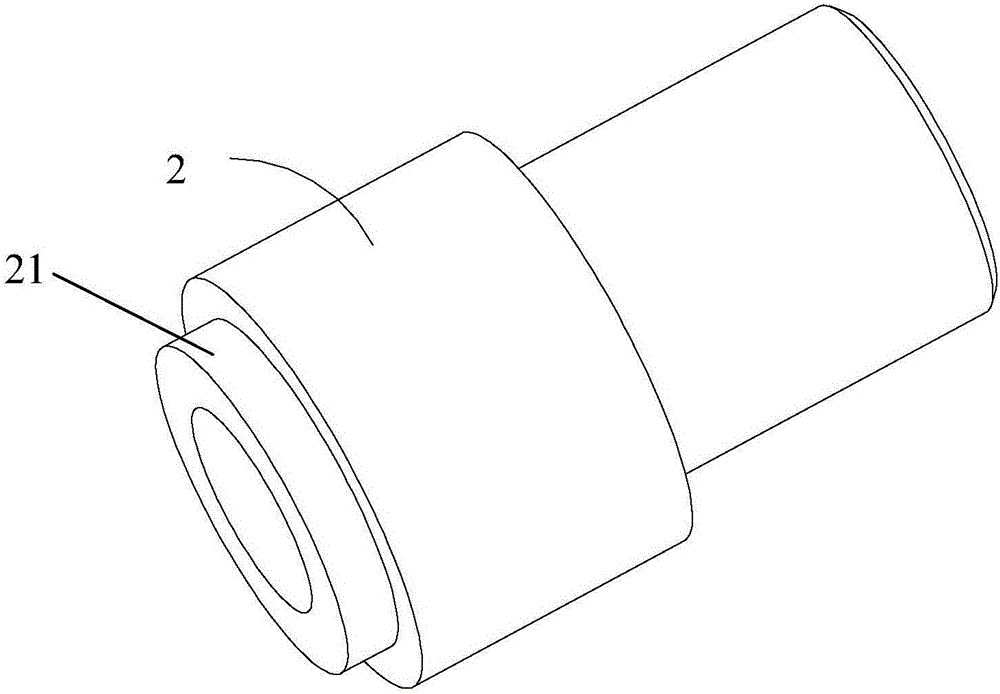

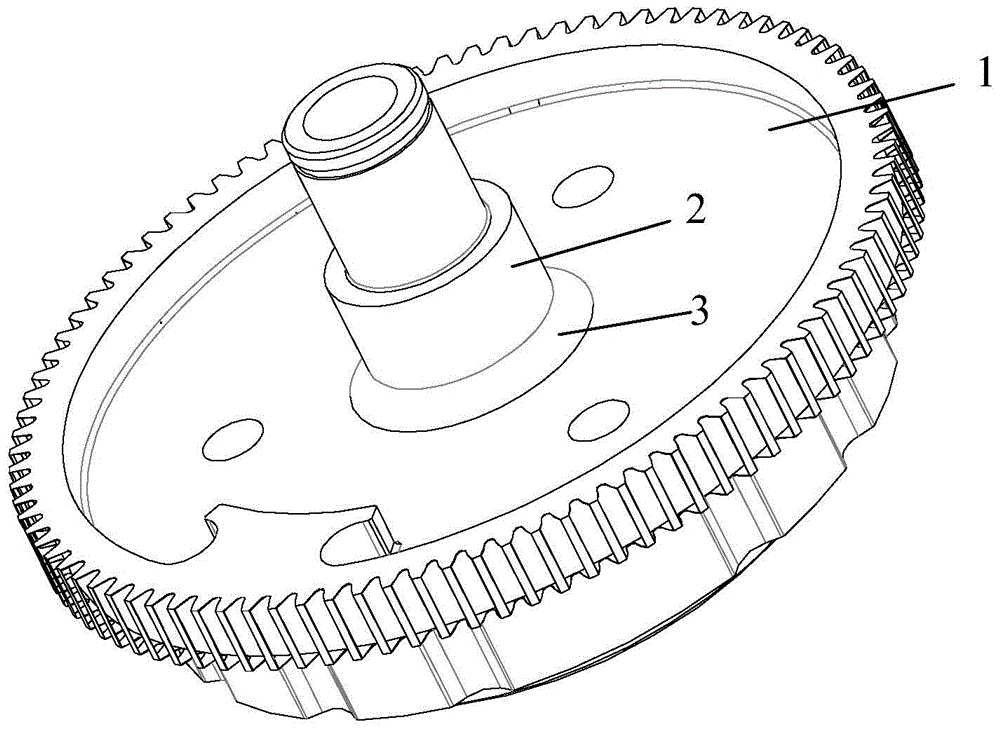

[0040] (2) suppression

[0041] Such as Figure 2-4 As shown, the above-mentioned hub gear base material is pressed to a density of 6.5g / cm 3 The base body of the hub gear, the above-mentioned hub gear shaft material is pressed to a density of 6.5g / cm 3 The hub gear shaft; the center of the hub gear base 1 is formed with a circular through hole 10 for accommodating the hub gear shaft 2, and the end of the hub gear shaft 2 is...

Embodiment 2

[0045]The preparation method of the powder metallurgy hub gear in this embodiment is characterized in that it includes the following steps:

[0046] (1) Design material composition

[0047] In terms of mass percentage, the material used for the hub gear base includes the following components: 0.2% carbon, 3% copper, unavoidable impurity elements below 2%, and iron as the balance;

[0048] In terms of mass percentage, the material used for the hub gear shaft includes the following components: 5% copper, 2% or less unavoidable impurity elements, and the balance is iron;

[0049] (2) suppression

[0050] Such as Figure 2-4 As shown, the above-mentioned hub gear base material is pressed to a density of 7g / cm 3 The base body of the hub gear, the above-mentioned hub gear shaft material is pressed to a density of 6.5g / cm 3 The hub gear shaft; the center of the hub gear base 1 is formed with a circular through hole 10 for accommodating the hub gear shaft 2, and the end of the hub...

Embodiment 3

[0054] The preparation method of the powder metallurgy hub gear in this embodiment is characterized in that it includes the following steps:

[0055] (1) Design material composition

[0056] In terms of mass percentage, the material used for the hub gear base includes the following components: 0.2% carbon, unavoidable impurity elements below 2%, and iron as the balance;

[0057] In terms of mass percentage, the material used for the hub gear shaft includes the following components: 1.0% carbon, 2% or less unavoidable impurity elements, and the balance is iron;

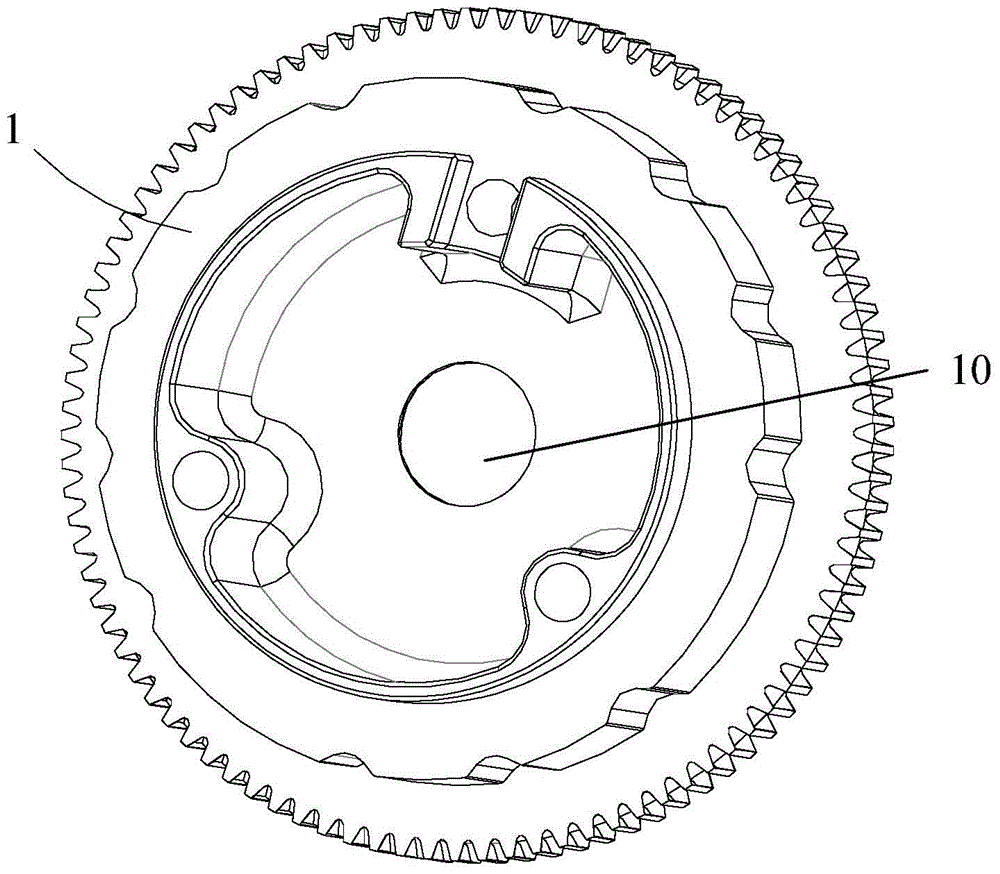

[0058] (2) suppression

[0059] Such as Figure 5-7 As shown, the above-mentioned hub gear base material is pressed to a density of 7.2g / cm 3 The base body of the hub gear, the above-mentioned hub gear shaft material is pressed to a density of 7.5g / cm 3 The hub gear shaft; the center of the hub gear base body 1 is formed with an inner spline-shaped through hole 10 for accommodating the hub gear shaft 2, and the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com