Extinguisher cylinder welding machine and welding method thereof

A fire extinguisher and cylinder technology, applied in the field of fire extinguisher cylinder welding machine and welding, can solve the problems of high labor intensity, low labor intensity, welding efficiency, low welding efficiency, etc., and achieves low labor intensity, high welding efficiency, and convenient grounding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

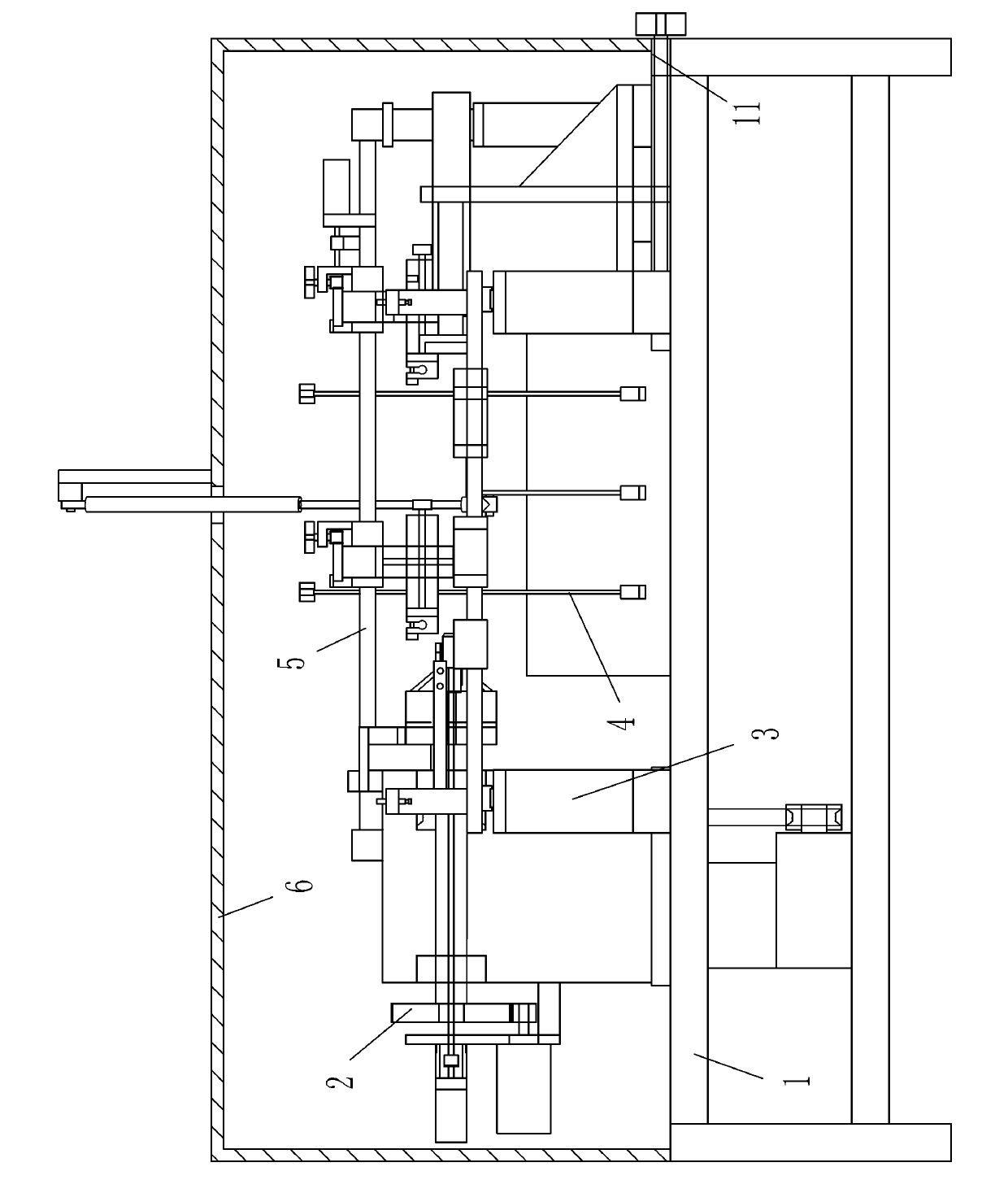

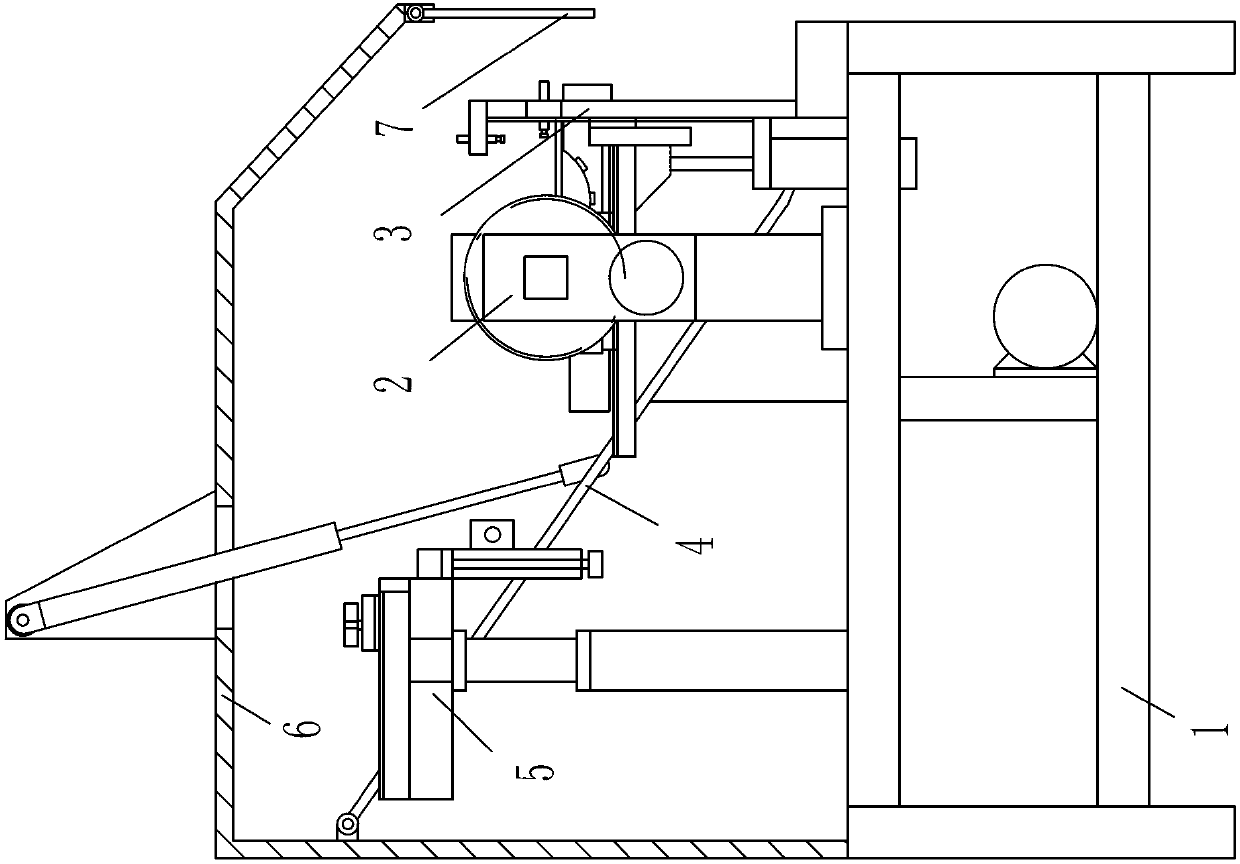

[0029] as attached figure 1 , attached figure 2 Shown: a fire extinguisher cylinder welding machine, which is characterized in that it includes a base 1, a cylinder clamping device 2, a cylinder entering device 3 located on the front side of the cylinder clamping device 2, a cylinder unloading device 4, The welding gun clamping device 5 located at the rear side of the cylinder clamping device 2, the protective shell 6 whose lower end is screwed to the base 1, and the observation plate 7 hinged with the front plate of the protective shell 6 through hinges; the material of the observation plate 7 is electric welding glass .

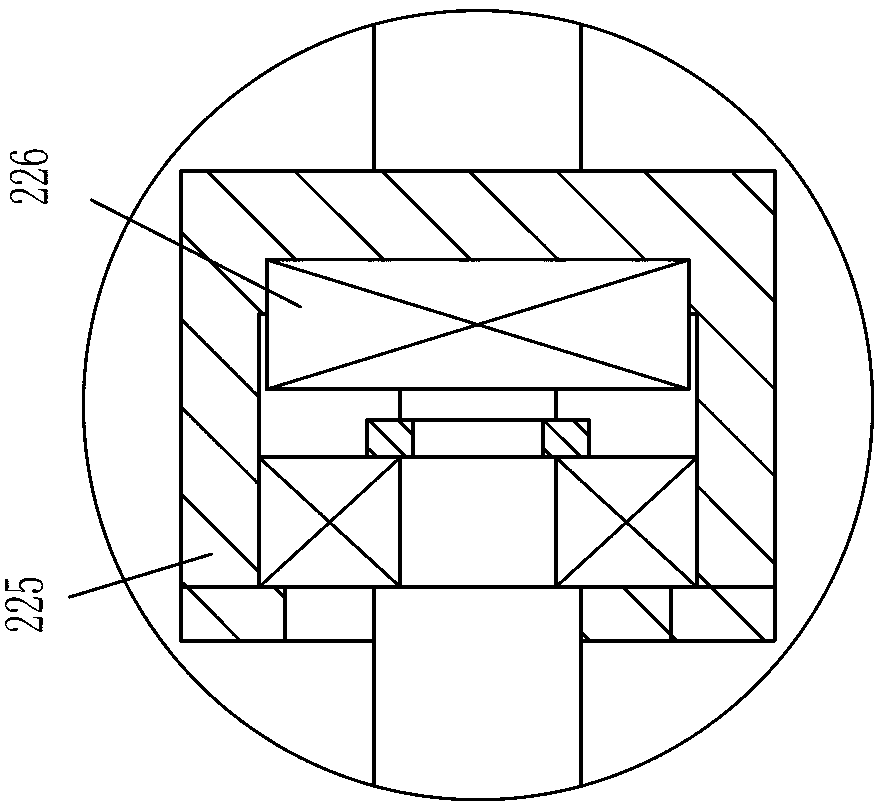

[0030] See attached image 3 , attached Figure 4 , the cylinder clamping device 2 includes a valve seat end mounting seat 22 screwed to the base 1, a valve seat positioning rod 23 with a convex key 231 on the outer side, and a bottom cover pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com