Fabrication method of miniature optical fiber Fabry-Perot interferometer with controllable cavity length

A manufacturing method and interferometer technology, applied in the direction of instruments, using optical devices, using optical devices to transmit sensing components, etc., can solve the problems of difficult control of structure size, difficulty in making FPI of optical fiber micro-air cavity, etc., and achieve adjustable welding parameters , flexible control of discharge times and discharge intensity, simple welding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

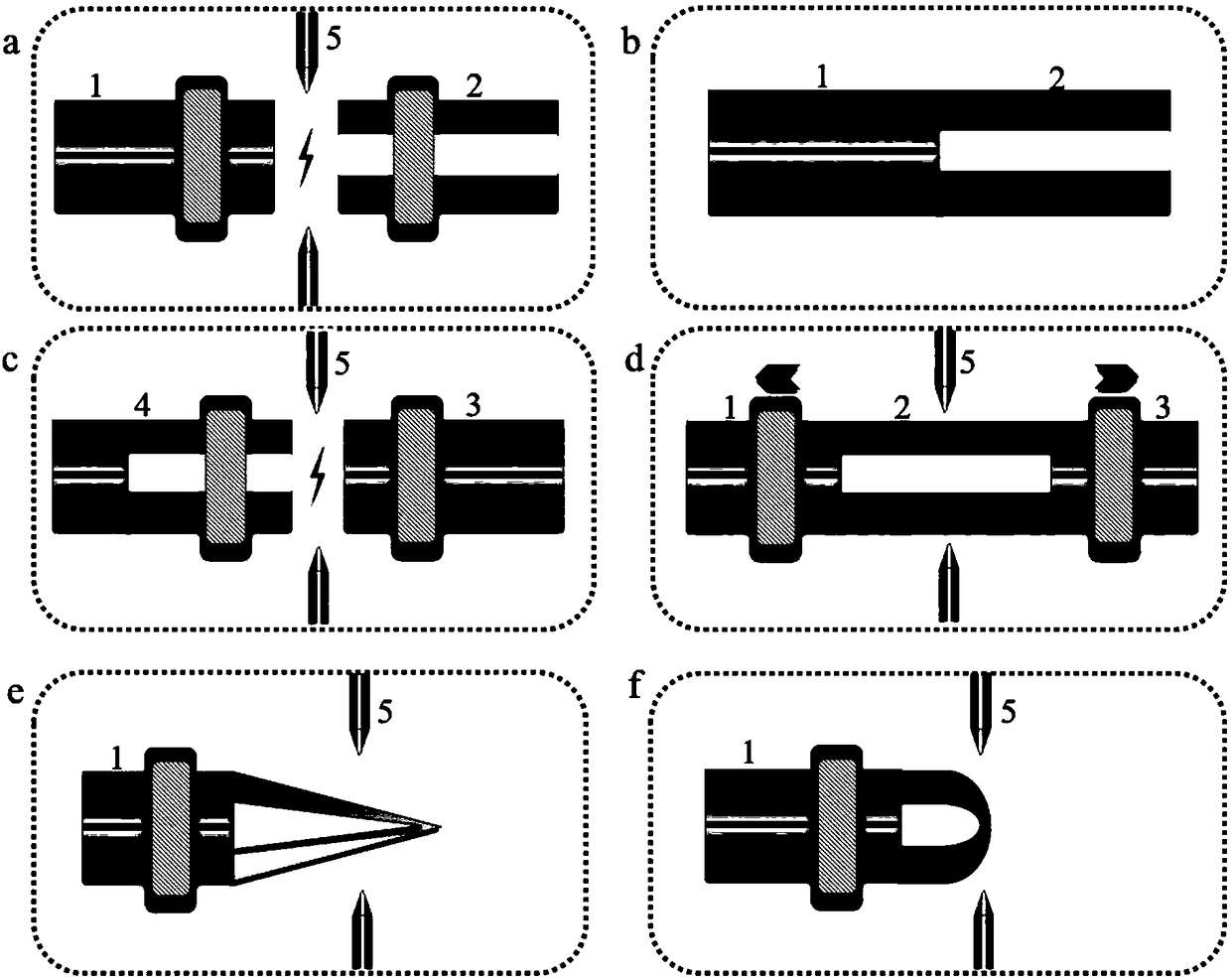

[0017] In order to make the above objects and advantages more comprehensible, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] The concrete implementation process of the present invention is as follows:

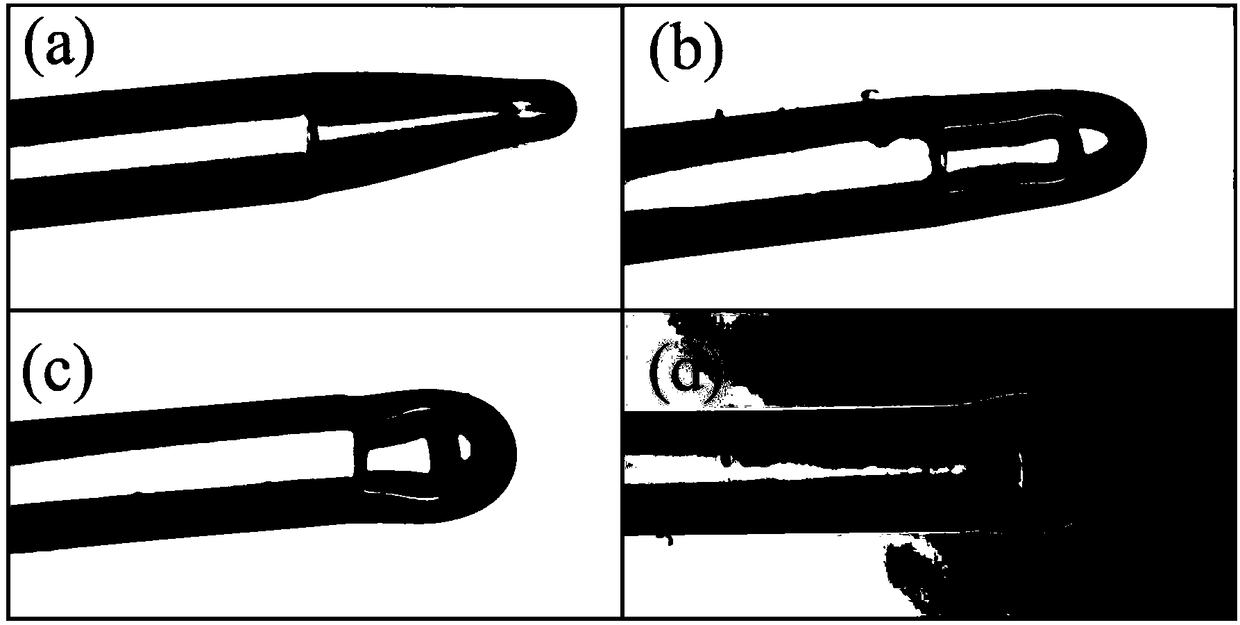

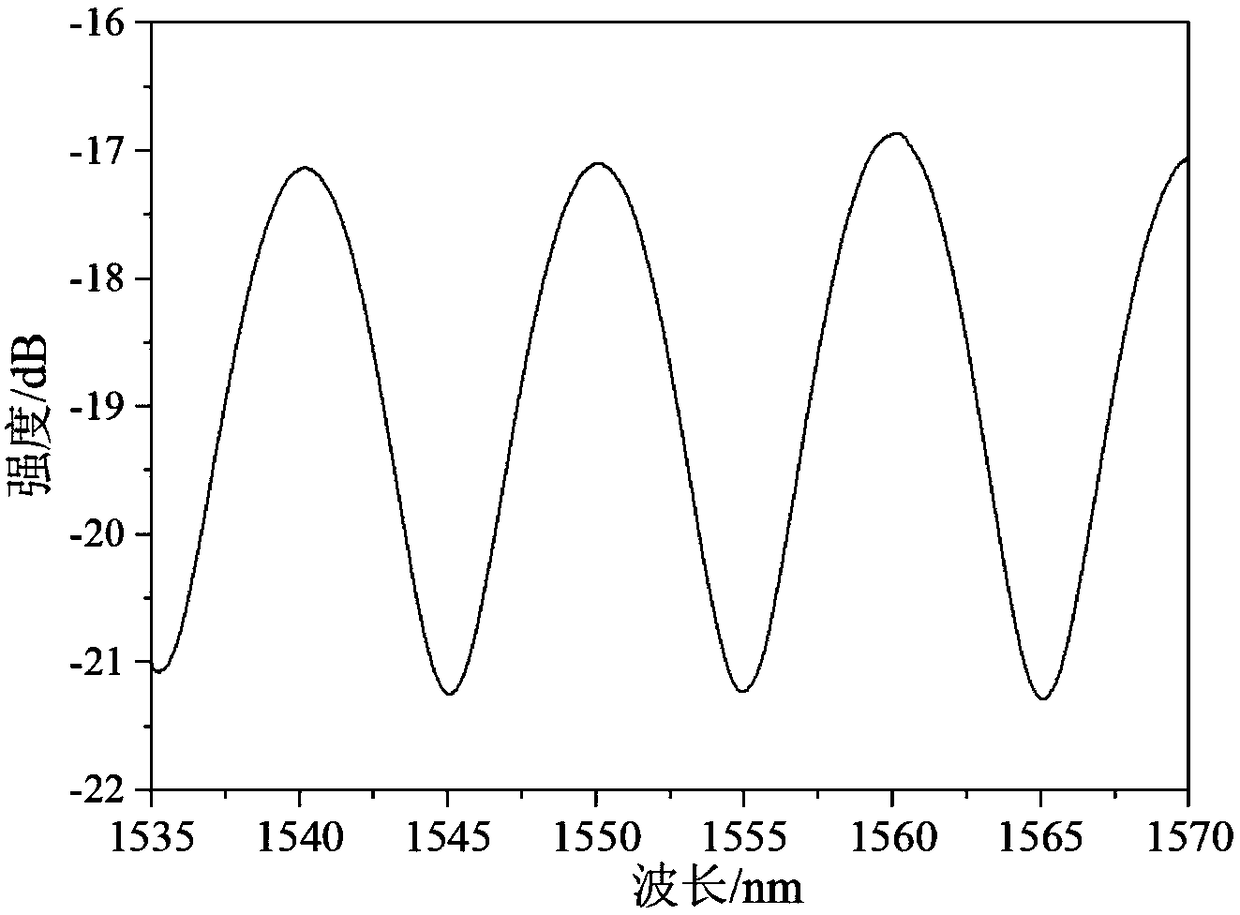

[0019] First, the single-mode fiber A1 is cut flat with a cutter, and then the single-mode fiber A1 and the hollow-core fiber 2 are spliced with a fusion splicer to form the single-mode fiber and the hollow-core fiber section 4, and then the single-mode fiber and the hollow-core fiber section 4 are connected to each other. The single-mode fiber B3 is spliced without collapse, and the spliced structure is discharged and tapered at the center of the hollow fiber by a fusion splicer. The parameters of the discharge arc are set to: discharge intensity 80unit, discharge time 200ms, and the single advance length of the electrode is 3μm. Until fusing, discharge at the cone head. With the incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com