Welding system and welding method for all-position automatic welding of small-diameter pipeline

An automatic welding and welding system technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as low efficiency, narrow operating space, and restricting welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

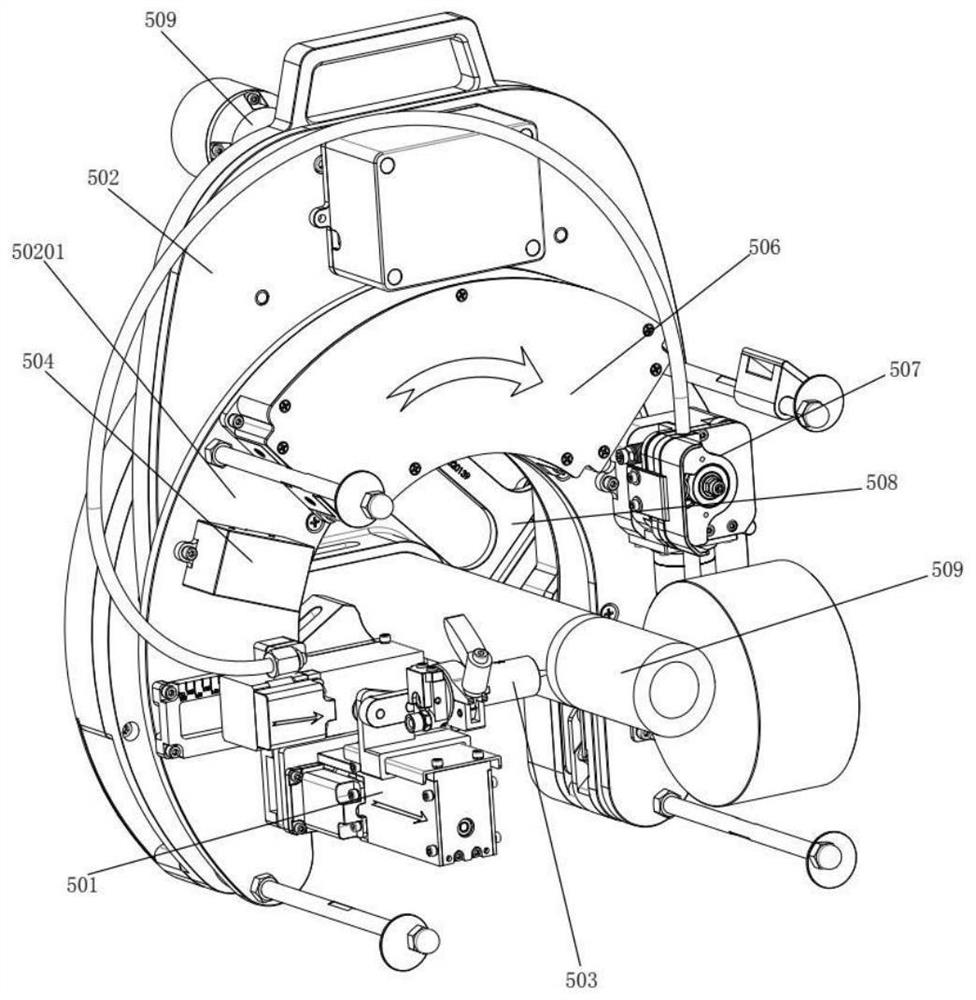

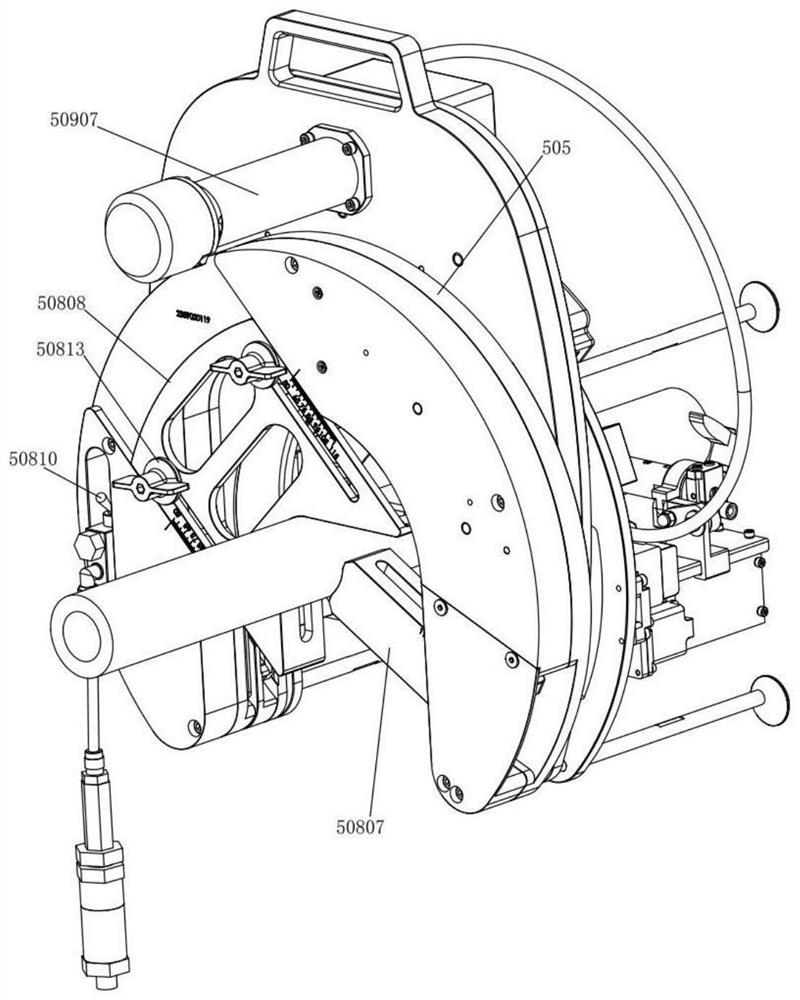

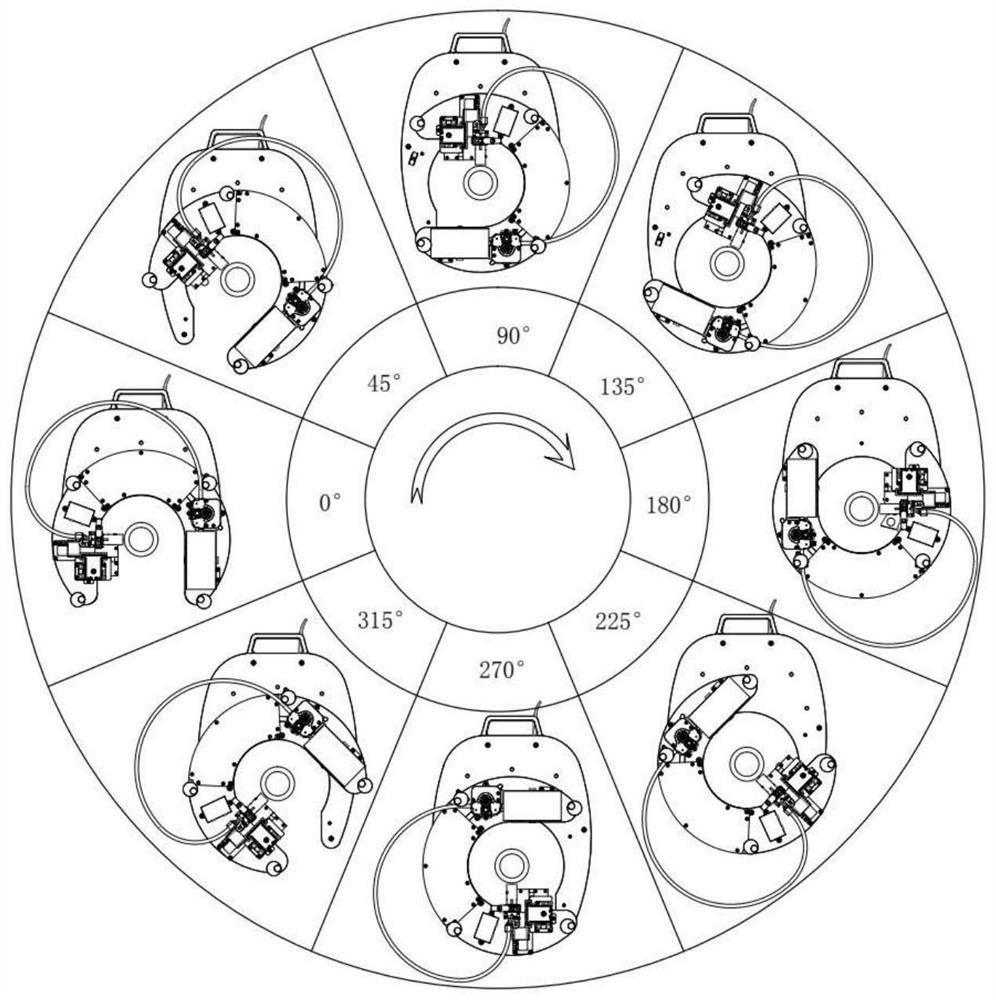

[0100] Such as figure 1 , figure 2 As shown, a welding system for all-position automatic welding of small-diameter pipelines provided by the present invention includes a welding trolley 5 and a pipe liner inner counterpart 6, and the welding trolley 5 is provided with a welding control module and a welding torch 503 And fast clamping device 508; Welding torch 503 is the working part that realizes welding task, and the electric energy during welding shielding gas, welding material and welding is all output here, specifically, welding torch 503 is existing multifunctional digital welding machine, A variety of welding modes can be provided, for example: welding modes include MIG, pulse, argon arc welding, pulse argon arc welding, etc., and the movement mode of the welding torch 503 includes normal (normal walking, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com