Tubulation welding method of stainless steel outer composite tube

A welding method, stainless steel technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of low welding efficiency, complicated welding process, large consumption of welding materials, etc., to save welding materials, simple welding method, durable Erosion good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

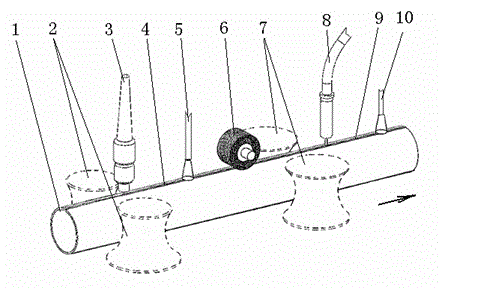

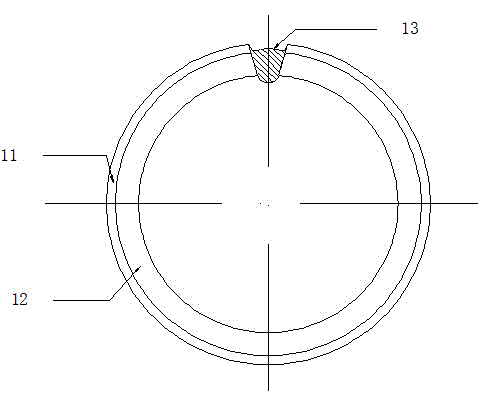

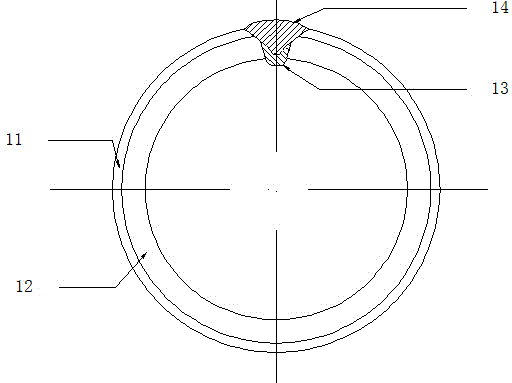

[0035] Such as figure 1 , 2 , 3.

[0036] The 2.0mm thick stainless steel clad plate to be welded (the base carbon steel 12 has a thickness of 1.6mm, and the stainless steel clad layer 11 has a thickness of 0.4mm) is made into a stainless steel outer clad pipe to be welded by the tube blank forming process before the welding process 1 , fixed in the vertical roller pair 2 and 7 to support the stainless steel outer composite pipe 1 to be welded, and at the same time control the welding gap of argon tungsten arc welding to be 0.2-0.8mm. Tungsten argon arc welding, natural slow cooling, forced water cooling, welding slag removal, gas shielded metal welding, natural slow cooling, and forced water cooling are all carried out in sequence during the movement of the tube blank formed by bending the stainless steel clad plate Yes, the moving speed of the tube blank formed by bending the stainless steel clad plate is 1.2m / min.

[0037] (1) Use argon tungsten arc welding torch 3 for a...

Embodiment 2

[0044] Such as figure 1 , 2 , 3.

[0045] The 3.0mm thick stainless steel composite plate to be welded (in which the thickness of the base carbon steel 12 is 2.4m, and the thickness of the stainless steel clad layer 11 is 0.6mm) is made into the stainless steel outer composite pipe 1 to be welded by the tube blank forming process before the welding process , fixed in the vertical roller pair 2 and 7 to support the stainless steel outer composite pipe 1 to be welded, and at the same time control the welding gap of argon tungsten arc welding to be 0.4-1mm. Tungsten argon arc welding, natural slow cooling, forced water cooling, welding slag removal, gas shielded metal welding, natural slow cooling, and forced water cooling are all carried out in sequence during the movement of the tube blank formed by bending the stainless steel clad plate Yes, the moving speed of the tube blank formed by bending the stainless steel clad plate is 0.8m / min.

[0046] (1) Use argon tungsten arc w...

Embodiment 3

[0053] Such as figure 1 , 2 , 3.

[0054] The 5.0mm thick stainless steel clad plate to be welded (in which the thickness of base carbon steel 12 is 4mm, and the thickness of stainless steel clad layer 11 is 1mm) is made into the stainless steel outer clad pipe 1 to be welded through the tube blank forming process before the welding process, and fixed In the vertical roller pair 2 and 7, to support the stainless steel outer composite pipe 1 to be welded, while controlling the welding gap of argon tungsten arc welding to be 1.5-2mm. Tungsten argon arc welding, natural slow cooling, forced water cooling, welding slag removal, gas shielded metal welding, natural slow cooling, and forced water cooling are all carried out in sequence during the movement of the tube blank formed by bending the stainless steel clad plate Yes, the moving speed of the tube blank formed by bending the stainless steel clad plate is 0.3m / min.

[0055] (1) Use argon tungsten arc welding torch 3 for argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com