Method for controlling welding cracks of ultrathin tantalum and molybdenum dissimilar materials

A technology for dissimilar materials and welding cracks, which is applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problem of difficulty in controlling welding cracks of thin-sheet tantalum/molybdenum dissimilar materials, and achieve low cost and good joint quality , The effect of eliminating joint cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method for controlling welding cracks of ultra-thin tantalum and molybdenum dissimilar materials can effectively control the welding cracks of thin tantalum / molybdenum dissimilar materials, and is realized through the following steps:

[0026] (1) Prepare the sample; use a wire cutting machine to cut the thin slice sample into 20×25mm, put the sample into the mixed solution of hydrofluoric acid: nitric acid: lactic acid = 1:3:5 and corrode it to 0.2mm, take it out with Rinse with clean water, dry with a hair dryer with cold air, remove oxides on the surface of the sample, and then smooth and align the two butt surfaces with sandpaper;

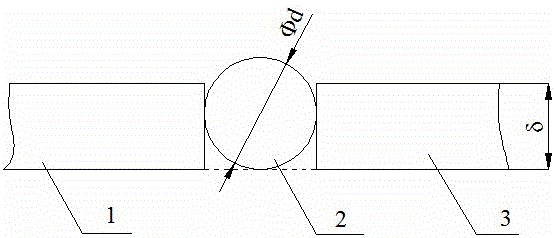

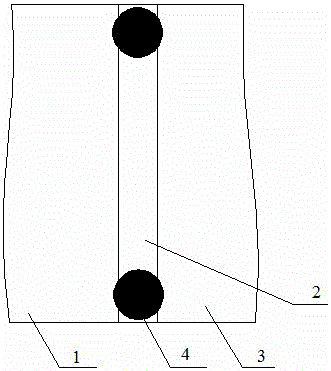

[0027] (2) Clamp the sample; align the butt joints ground with sandpaper, place a pre-selected TC4 wire with a suitable diameter in the middle, fix it with a fixture, and cover it with a glass cover;

[0028] (3) Positioning before welding: Introduce Ar gas with a purity of 99.9% into the glass cover for 3 minutes, remove the air in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com