Laser heating friction welding method

A laser heating and friction welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the heating area is not easy to control, the workpiece is not suitable for friction welding, and the heat-affected zone softens, etc., to achieve green production efficiency Effects of environmental protection, rich content and variety, expansion of content and variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific embodiment one: present embodiment is carried out as follows:

[0031] 1. The end face of the pipe fittings to be welded is deoxidized and dirt-treated until the surface of the workpiece reveals the true color of the metal.

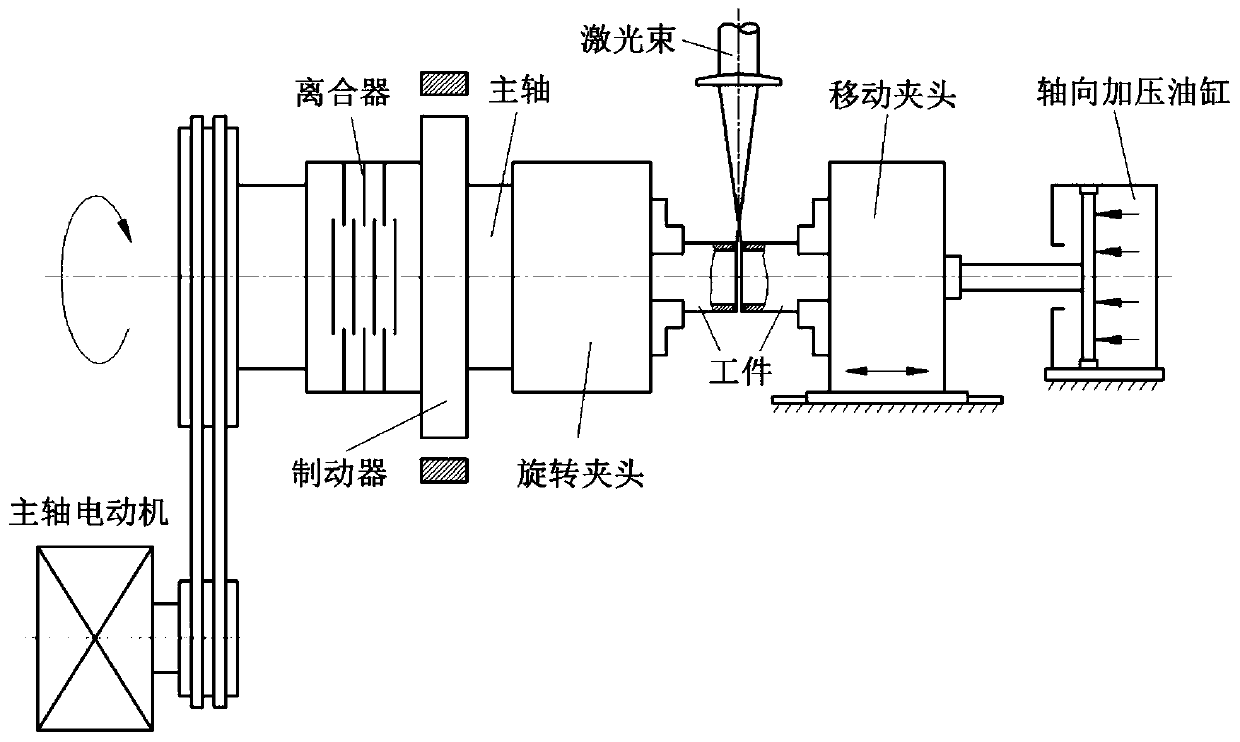

[0032] 2. If figure 1 , firmly install the workpiece to be welded on the chuck, reserve a gap of 1mm between the end faces of workpiece 1 and workpiece 2 to be welded, turn on the power to rotate workpiece 1 at a rotation speed of 500r / min, and check the concentricity and roundness of the workpiece .

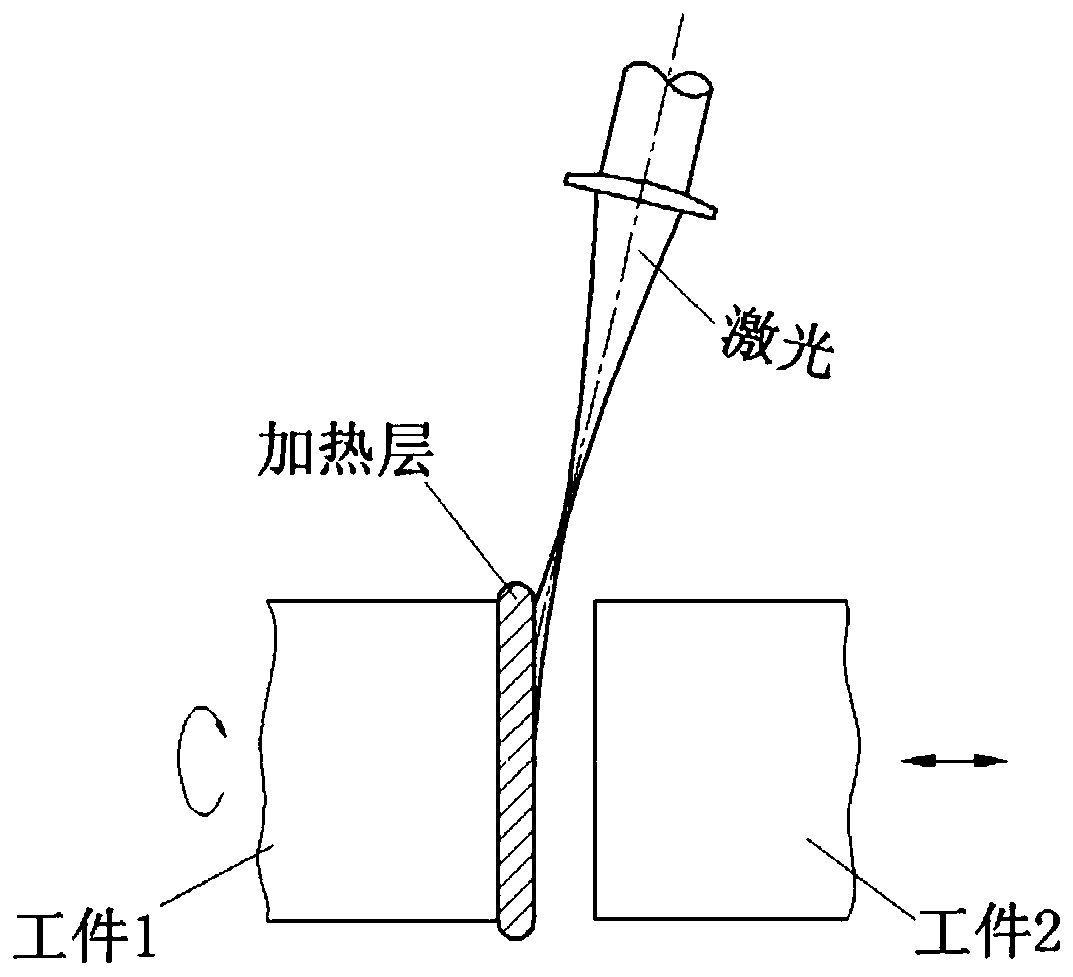

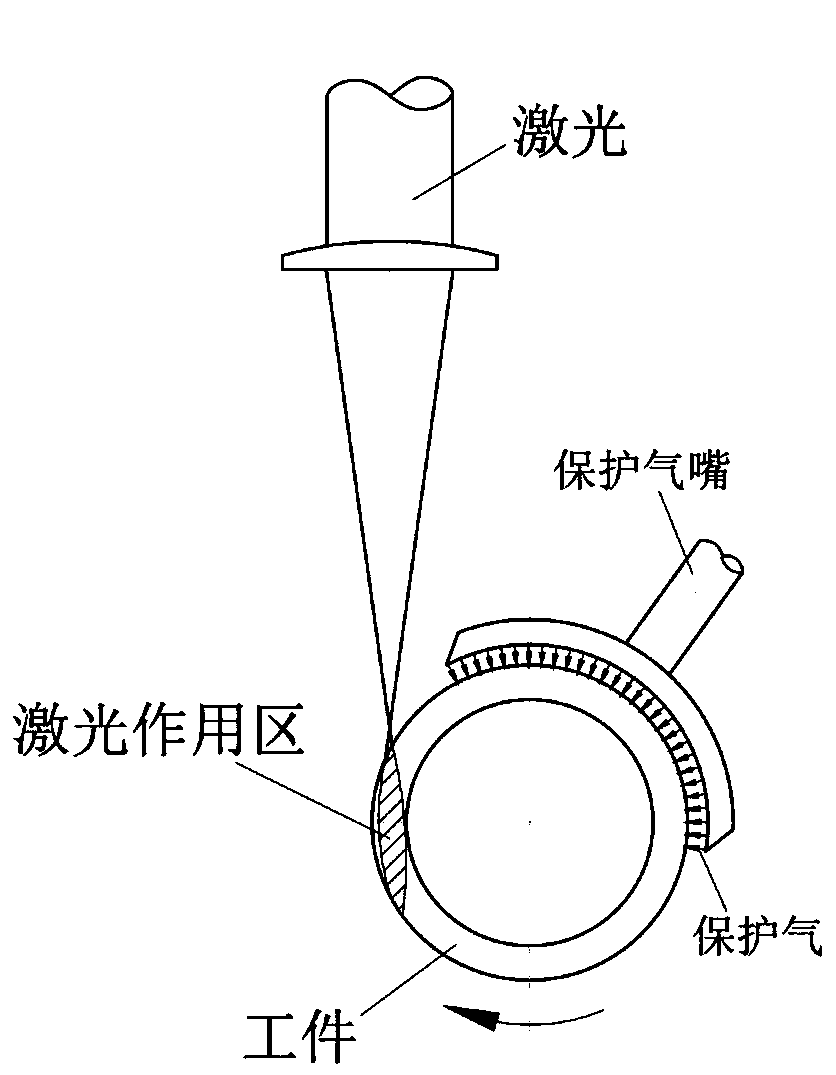

[0033] 3. If figure 2 , the beam deflection angle (the angle between the laser beam and the workpiece end face) is set to 20°, and the spot size is 0.5mm 2 ~40mm 2 Between, the laser power is 1000W. like image 3 , adjust the laser action position near the tangent line of the ring, set up argon gas protection in the welding area, the gas flow rate is 30L / min, and the gas protection range is 150° in the angular direction.

[0034] 4...

specific Embodiment approach 2

[0036] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the laser spot shape can be multi-spot, rectangular spot, arc-shaped spot, etc. in addition to circular, such as Figure 4 , other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 is that a beam of laser heats two workpieces 1 and 2 with opposite rotation directions at the same time, such as Figure 5 , other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com