Oppositely-opening type connecting pipe rotary device

A rotating device, split-type technology, applied in auxiliary devices, welding equipment, tubular objects, etc., can solve the problems of inconvenient disassembly, large workload, low efficiency, etc., and achieve the effects of easy operation, high productivity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

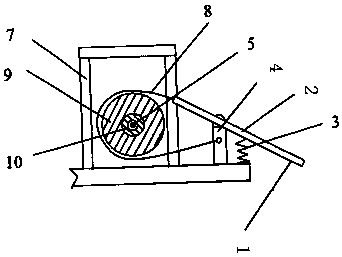

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A split connecting pipe rotating device described in this example is characterized in that it includes a base, a split pipe mold, and a sliding clamp for locking, and the groove width of the base matches the thickness of the belt pulley.

[0011] The split connecting pipe rotating device according to claim 1, characterized in that, the copper pipe blank is installed in the rotating fixture, and the split pipe mold is locked with the rotating fixture, and the sliding fixture is locked and arranged at The side wall of the base penetrates into the groove.

[0012] The split connecting pipe rotating device according to claim 1, wherein the welding end surface of the copper tube blank protrudes, and the copper tube blank and the aluminum tube blank are located on the same axis.

[0013] When maintaining the engine, there is no need to remove other accessory parts, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com