Method for connecting glass with copper or copper alloy

A connection method and copper alloy technology, which is applied in the field of connection between glass and copper or copper alloy, can solve the problems of complex process, high connection temperature, and low joint quality, and achieve simple fixtures, energy saving, and easy brazing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

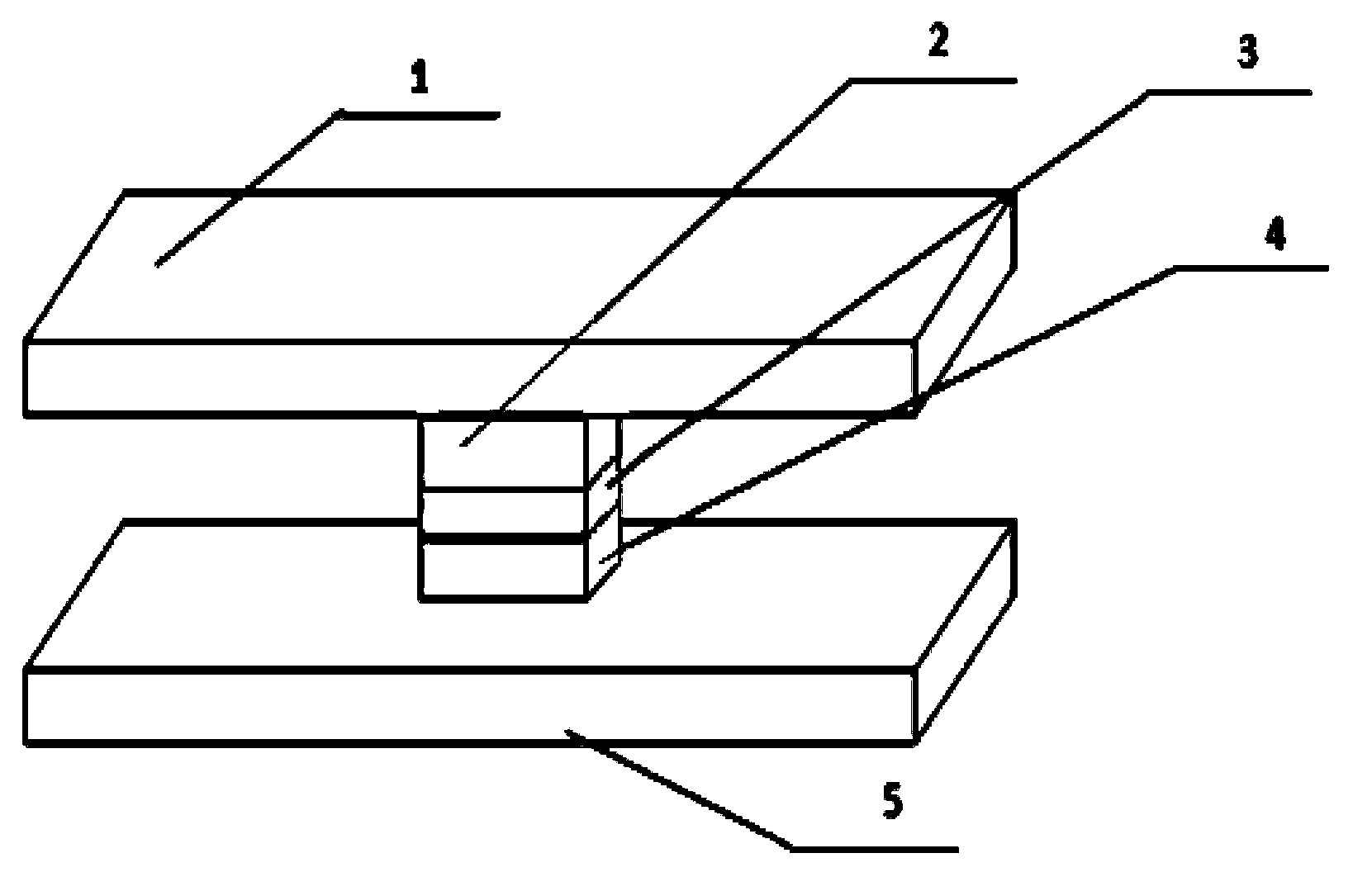

[0016] Specific implementation mode 1: (Please refer to the attached figure 1 ) The connection method between glass and copper or copper alloy in this embodiment is implemented according to the following steps:

[0017] 1. Put the polished copper or copper alloy into acetone for ultrasonic cleaning for 8-15 minutes, then wash with absolute ethanol and deionized water respectively, dry it in a drying box and dry to obtain the surface-treated copper or copper alloy;

[0018] 2. Put the polished glass substrate into acetone for ultrasonic cleaning for 8 to 15 minutes, then clean it with absolute ethanol and deionized water respectively, and blow dry to obtain the cleaned glass substrate. The cleaned glass substrate is bombarded with ion beams. film for 3 to 5 minutes, and then use electron beams to vapor-deposit a Cr film with a thickness of 250-350 nm on the glass substrate, and then vapor-deposit a Cu film with a thickness of 700-900 nm to obtain a coated glass substrate;

[...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the copper or copper alloy after grinding in step 1 is polished with silicon carbide water sandpaper, and the grinding process is to use 80# sandpaper, 240# silicon carbide water sandpaper, 400 #sandpaper, 600# sandpaper, 800# sandpaper, 1000# sandpaper in the order of sanding step by step. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the glass substrate polished in step 2 is polished with #80 silicon carbide water sandpaper. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com