Saddle-shaped track automation welding method of collection box large tube socket

A technology of automatic welding and large pipe socket, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee welding quality, long manufacturing cycle, high labor intensity, etc., and achieve suitable temperature between weld layers and joints The effect of good quality and reasonable weld bead arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

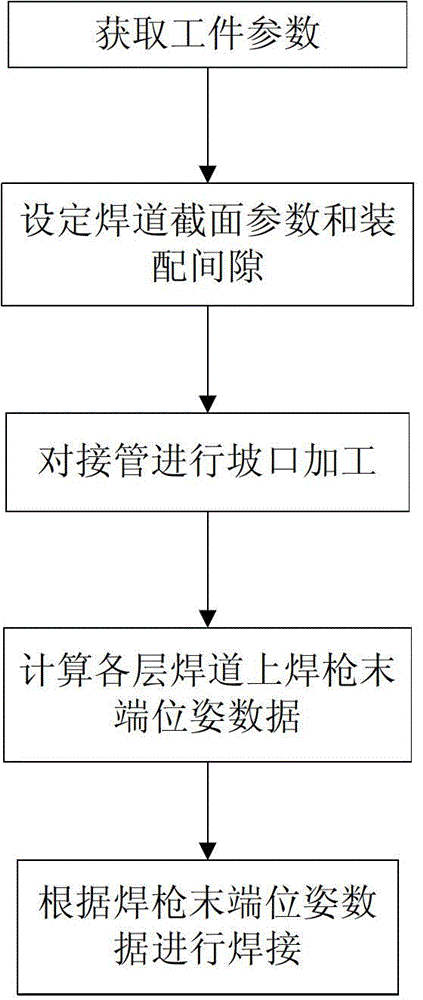

[0032] Such as figure 1 As shown, the present invention provides a saddle-shaped track automatic welding method for the large pipe seat of the header, comprising the following steps:

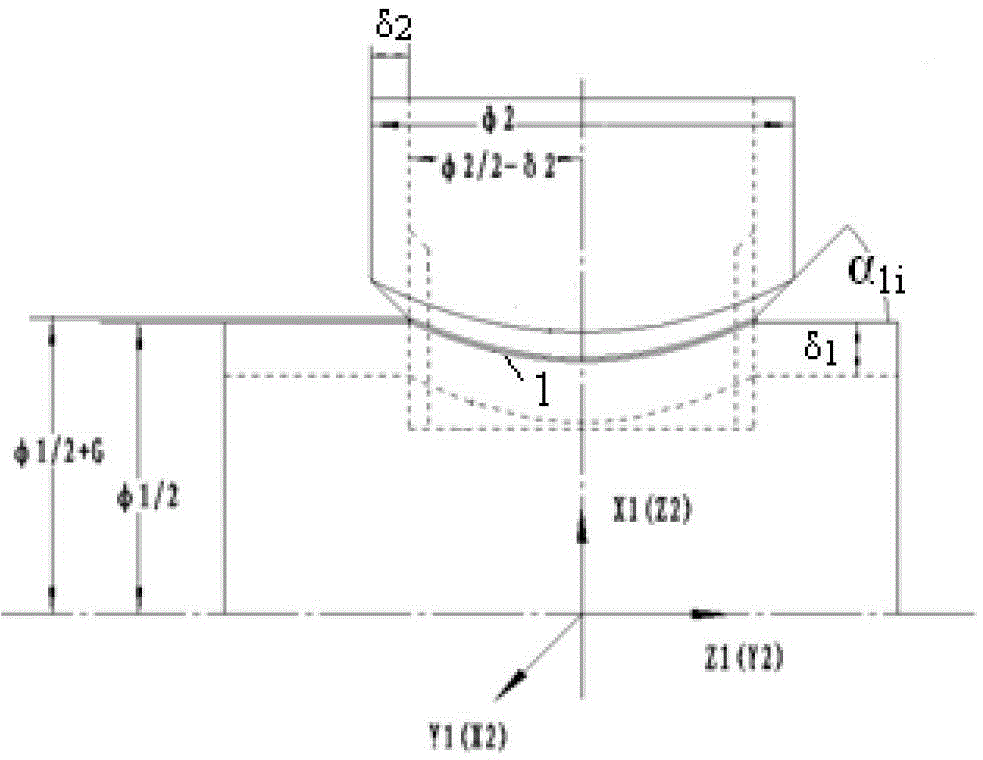

[0033] Step 1: Obtain the workpiece parameters, including: the outer diameter φ of the parent pipe 1 and thickness δ 1 , the outer diameter φ of the connecting pipe connected to the main pipe 2 and thickness δ 2 .

[0034] If necessary, a liner (thickness: 10-15mm) for backing welding can be installed in the connecting pipe, and the thickness and length of the liner should be obtained.

[0035] Preferably, b is the connection thickness δ 2 2.5 times of that, the assembly gap G is 2-3mm.

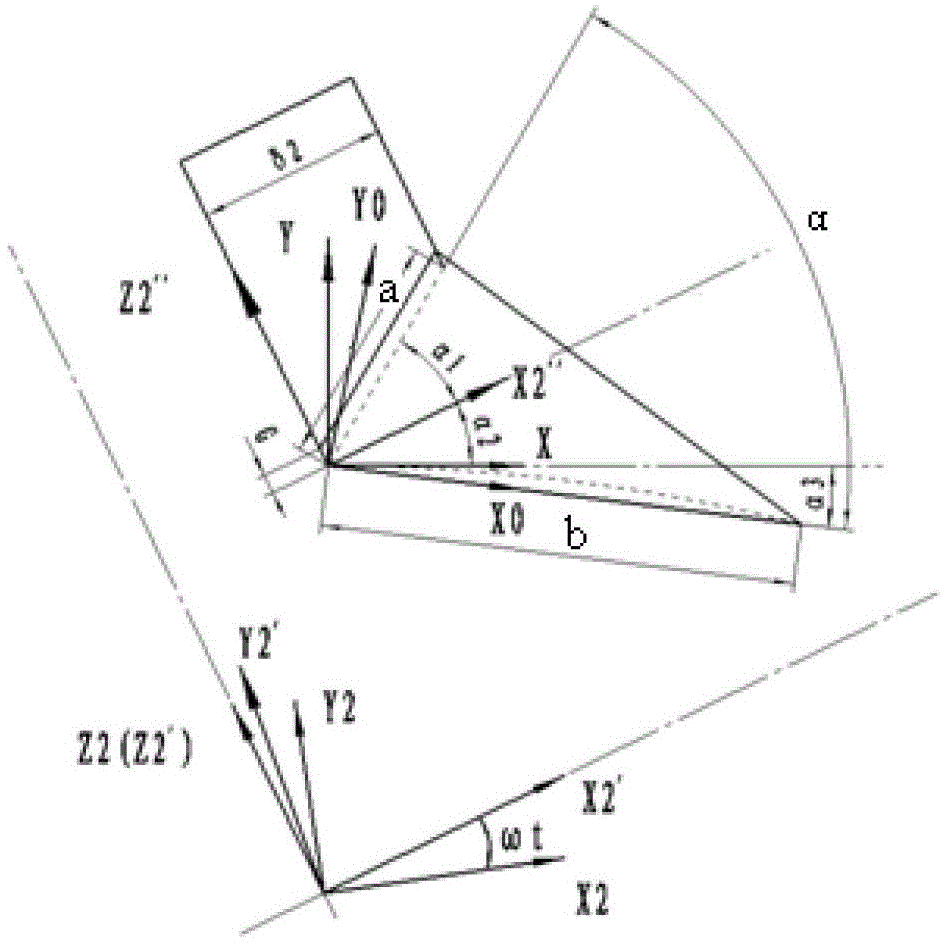

[0036] Step 2: Set the welding bead section parameters and the assembly gap G between the main pipe and the connecting pipe (the relevant parameters are marked in figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com