Laser welding method of aluminum alloy and plastic, grinding jig and clamping jig

A technology of laser welding and aluminum alloy, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of small butt joint area of thin plates, difficult connection, poor wettability of metal and plastic, etc., and achieve fast welding speed and joint The effect of good quality and less stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

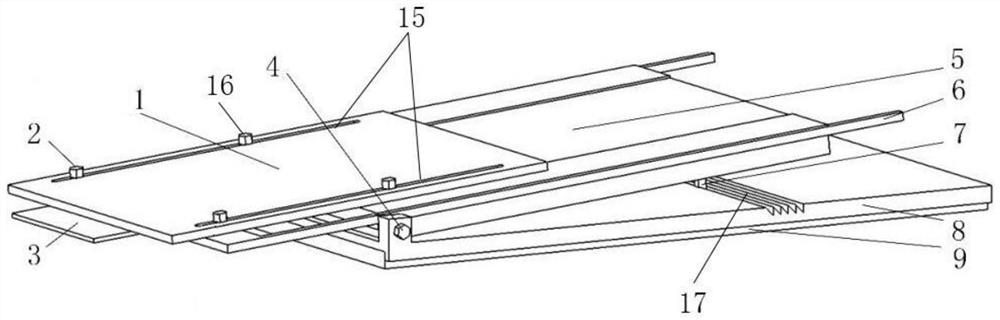

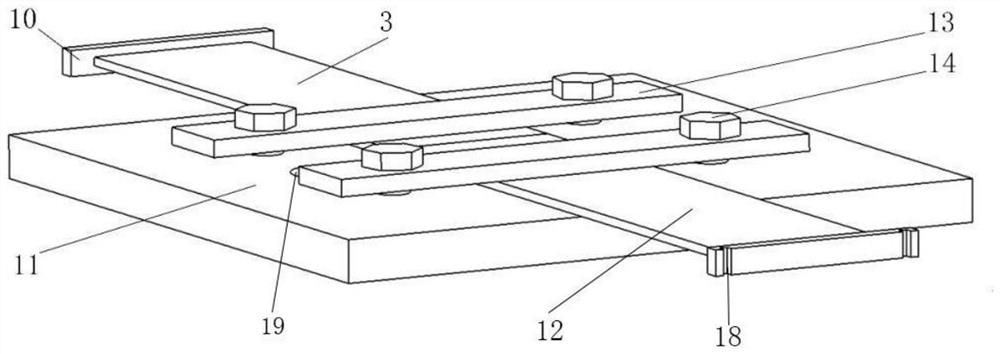

[0027] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0028] A kind of laser welding method of aluminum alloy and plastics, it comprises the steps:

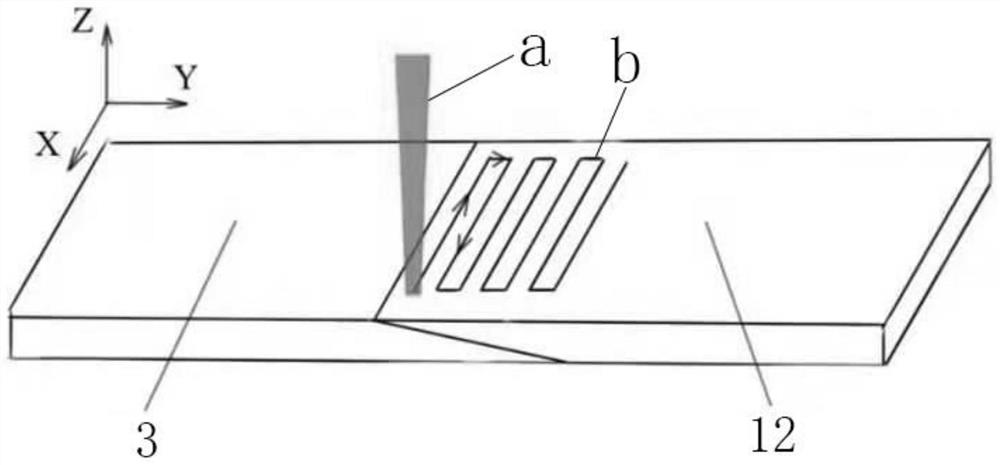

[0029] (1) Surface grinding treatment of the joint end faces of the aluminum alloy sample 3 and the plastic sample 12: the aluminum alloy sample 3 and the plastic sample 12 are plates of equal thickness with a thickness of 1-4mm, and the plastic sample 12 must It has thermoplasticity, that is, it can become soft and even flow after heating. It adopts the form of lap joint and butt joint hybrid joint, and uses the grinding fixture in the present invention to carry out surface treatment on the aluminum alloy sample 3 and plastic sample 12 respectively. After grinding, the aluminum alloy The inclinations of the end surfaces of the joints in sample 3 and plastic sample 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com