Welding device and method for improving hook-shaped defects of friction stir welding overlap joint

A technology for lap joints and hook defects, applied in the field of welding devices for improving friction stir welding lap joints, to achieve the effects of avoiding adverse effects, simple operation, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

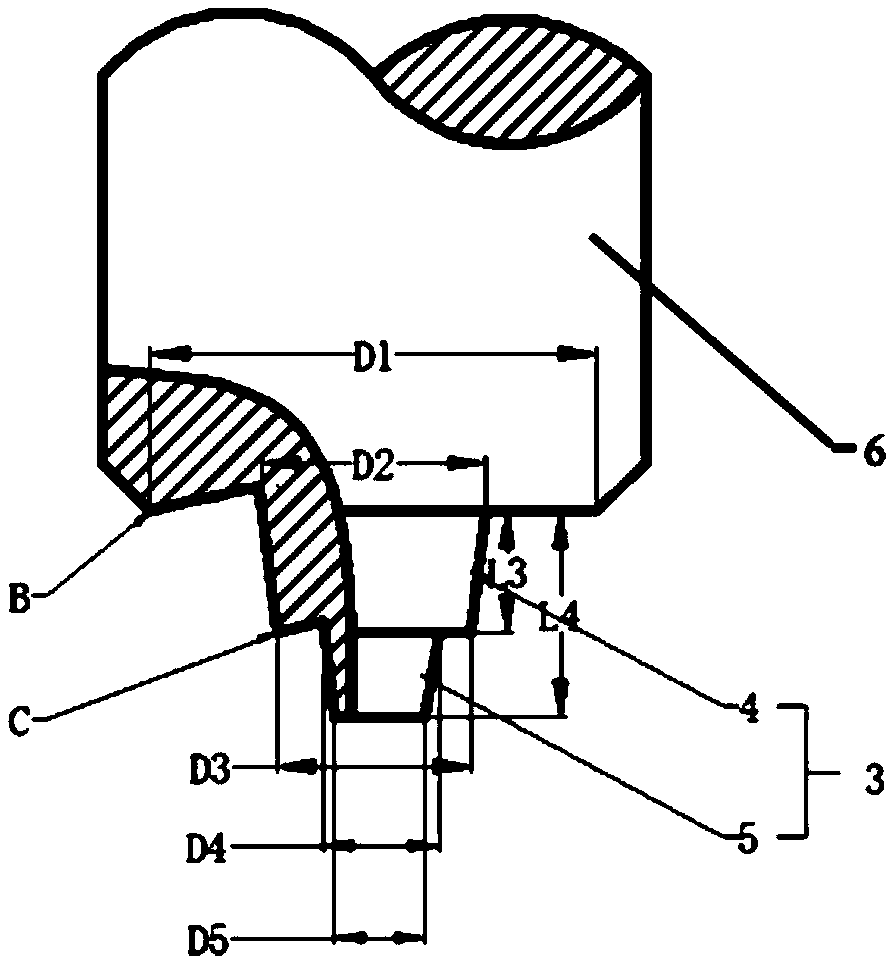

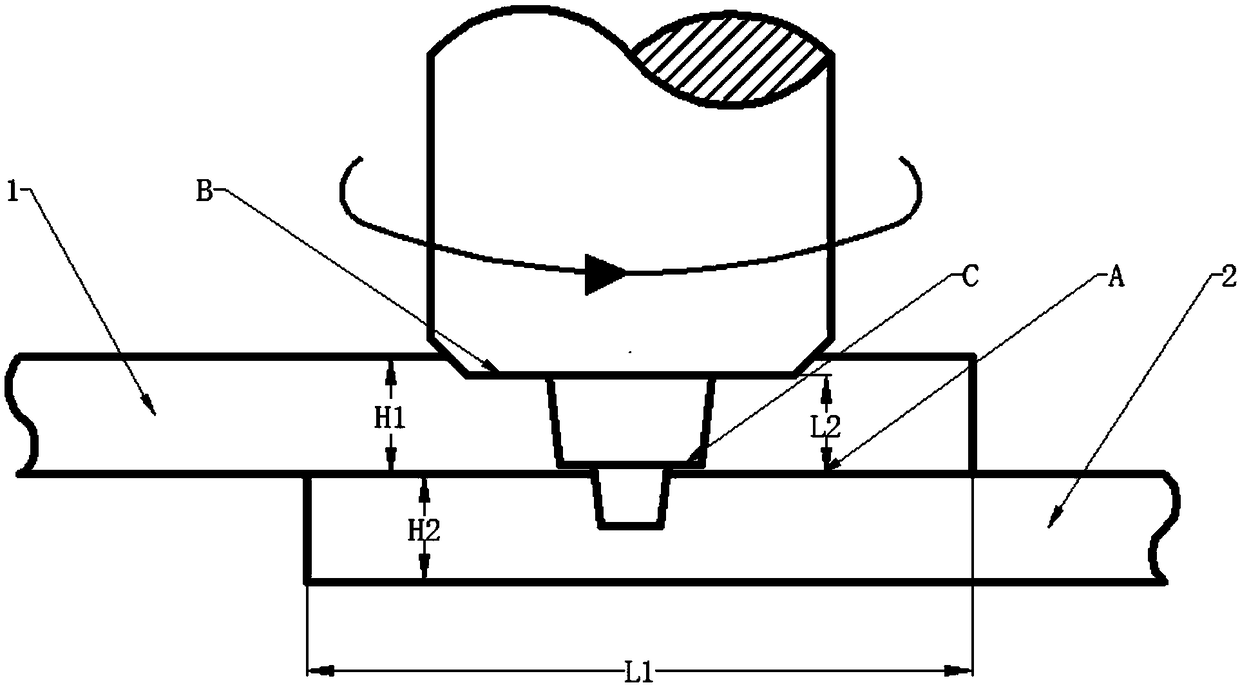

Embodiment 1

[0032] The first aluminum alloy plate to be welded with H1 = 4mm and the second aluminum alloy plate to be welded with H2 = 4mm are assembled with a lap joint structure to form the lap joint surface A, and the length L1 of the lap joint surface is selected as 15mm. Then use the above-mentioned welding device and welding method to carry out friction stir welding: the total length of the stirring needle L4=5.4mm, the length of the first-stage stirring needle L3=3.65mm, the downward pressure=0.2mm, the diameter of the upper and bottom surface of the first-stage stirring needle D2=8mm, Bottom diameter D3=8mm, upper bottom diameter D4=4mm of secondary stirring needle, lower bottom diameter D5=4mm, end surface of primary stirring needle is convex, shaft shoulder diameter D1=18mm, stirring head speed 1400r / min, welding The speed is 600mm / min. The microstructure analysis of the welded aluminum alloy sheet is as follows: image 3As shown, the results show that the "HOOK" in the joint ...

Embodiment 2

[0034] The first aluminum alloy plate to be welded with H1 = 4mm and the second aluminum alloy plate to be welded with H2 = 4mm are assembled with a lap joint structure to form the lap joint surface A, and the length L1 of the lap joint surface is selected as 15mm. Then use the above-mentioned welding device and welding method to carry out friction stir welding: the total length of the stirring needle L4=5.4mm, the length of the first-stage stirring needle L3=3.65mm, the downward pressure=0.2mm, the diameter of the upper and bottom surface of the first-stage stirring needle D2=6mm, Bottom surface diameter D3=6mm, upper bottom surface diameter D4=4mm of secondary stirring needle, lower bottom surface diameter D5=4mm, end surface shape of primary stirring needle is concave surface, shaft shoulder diameter D1=18mm, stirring head rotating speed is 2000r / min, welding speed It is 200mm / min. The microstructure analysis of the welded aluminum alloy sheet is as follows: Figure 4 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com