A Welding Device and Method for Improving Hook Defects in Friction Stir Welded Lap Joints

A technology for lap joints and hook defects, applied in the field of welding devices for improving friction stir welding lap joints, to achieve the effects of increasing effective load-bearing thickness, simple operation, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

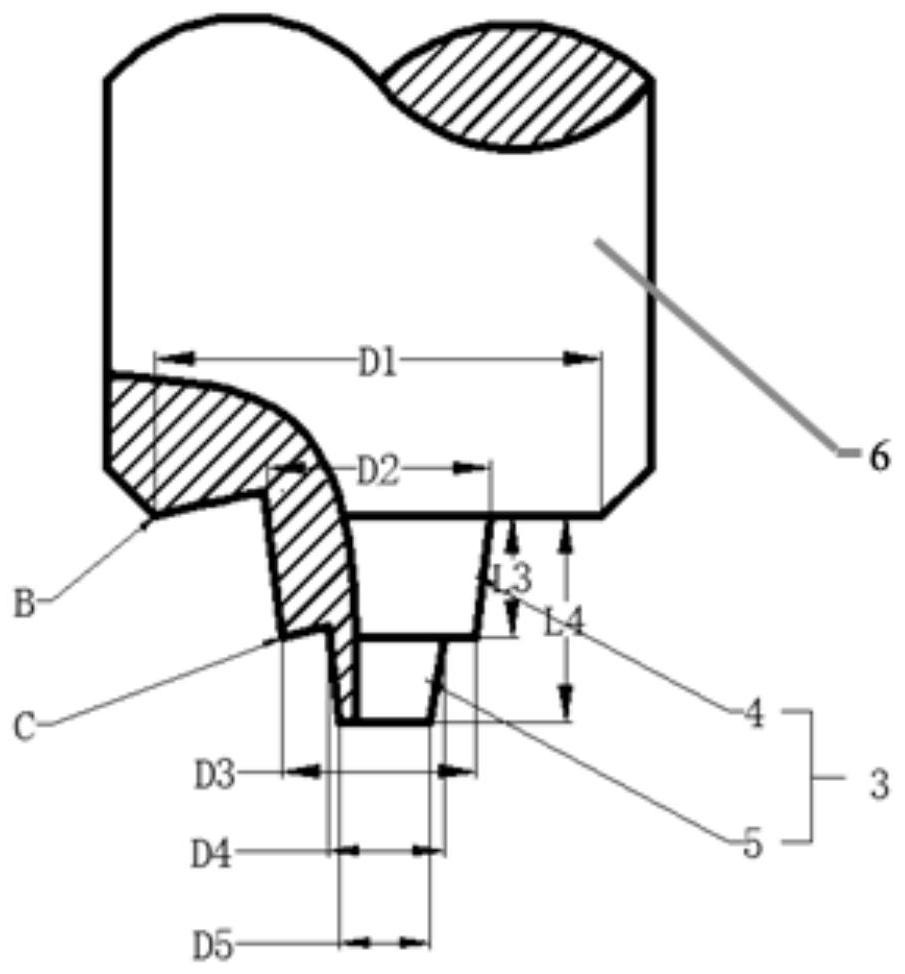

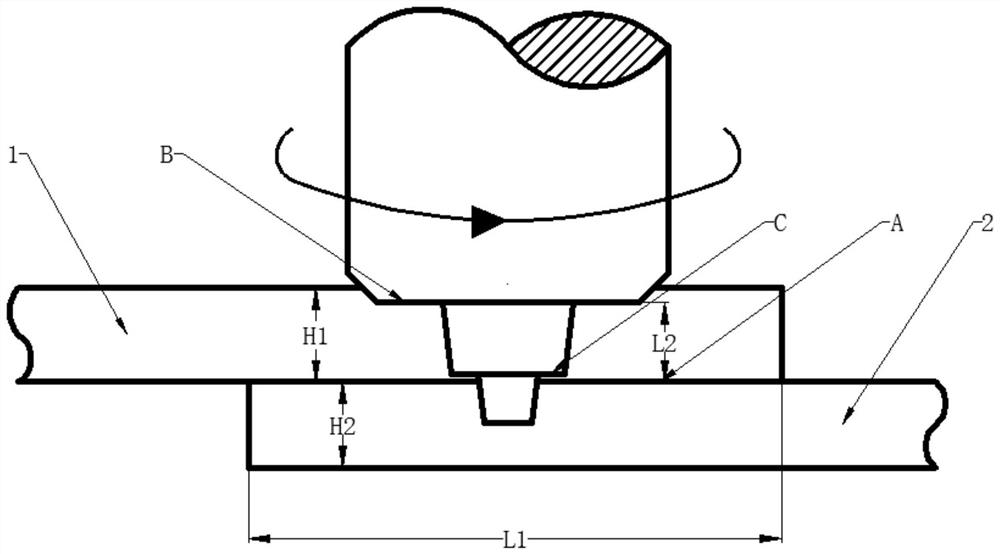

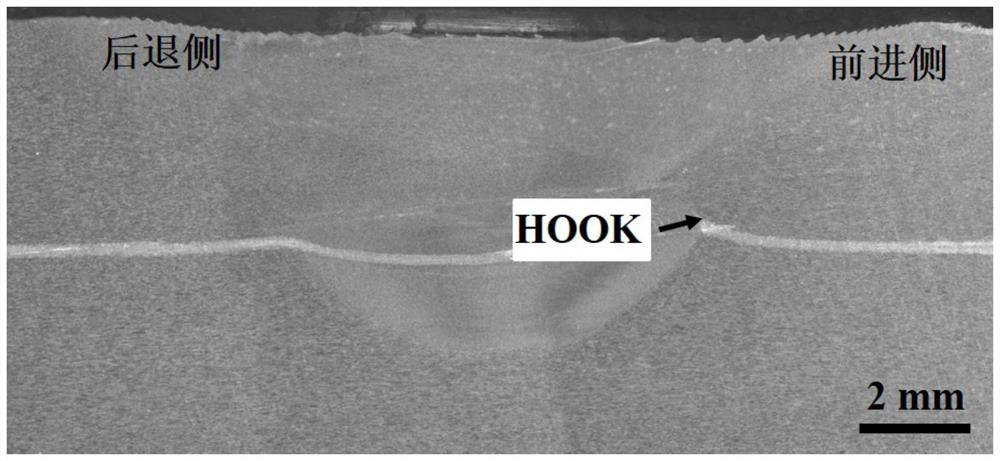

Embodiment 1

[0032] The first aluminum alloy plate to be welded with H1 = 4mm and the second aluminum alloy plate to be welded with H2 = 4mm are assembled with a lap joint structure to form the lap joint surface A, and the length L1 of the lap joint surface is selected as 15mm. Then use the above-mentioned welding device and welding method to carry out friction stir welding: the total length of the stirring needle L4=5.4mm, the length of the first-stage stirring needle L3=3.65mm, the downward pressure=0.2mm, the diameter of the upper and bottom surface of the first-stage stirring needle D2=8mm, Bottom diameter D3=8mm, upper bottom diameter D4=4mm of secondary stirring needle, lower bottom diameter D5=4mm, end surface of primary stirring needle is convex, shaft shoulder diameter D1=18mm, stirring head speed 1400r / min, welding The speed is 600mm / min. The microstructure analysis of the welded aluminum alloy sheet is as follows: image 3As shown, the results show that the "HOOK" in the joint ...

Embodiment 2

[0034] The first aluminum alloy plate to be welded with H1 = 4mm and the second aluminum alloy plate to be welded with H2 = 4mm are assembled with a lap joint structure to form the lap joint surface A, and the length L1 of the lap joint surface is selected as 15mm. Then use the above-mentioned welding device and welding method to carry out friction stir welding: the total length of the stirring needle L4=5.4mm, the length of the first-stage stirring needle L3=3.65mm, the downward pressure=0.2mm, the diameter of the upper and bottom surface of the first-stage stirring needle D2=6mm, Bottom surface diameter D3=6mm, upper bottom surface diameter D4=4mm of secondary stirring needle, lower bottom surface diameter D5=4mm, end surface shape of primary stirring needle is concave surface, shaft shoulder diameter D1=18mm, stirring head rotating speed is 2000r / min, welding speed It is 200mm / min. The microstructure analysis of the welded aluminum alloy sheet is as follows: Figure 4 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com