Impact rolling machine head for welding and welding with trailing device

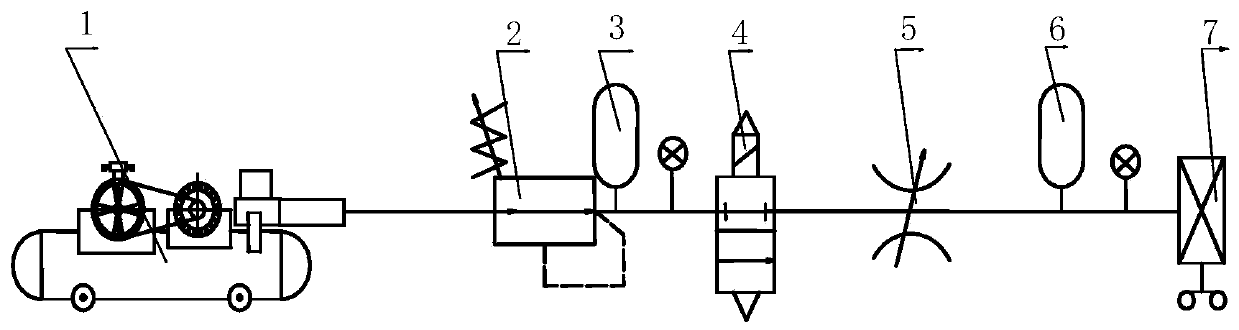

A technology of impact rolling and machine head, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of cold cracks, hot cracks, etc., to prevent delayed cold cracks, easy to use, simple and compact equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

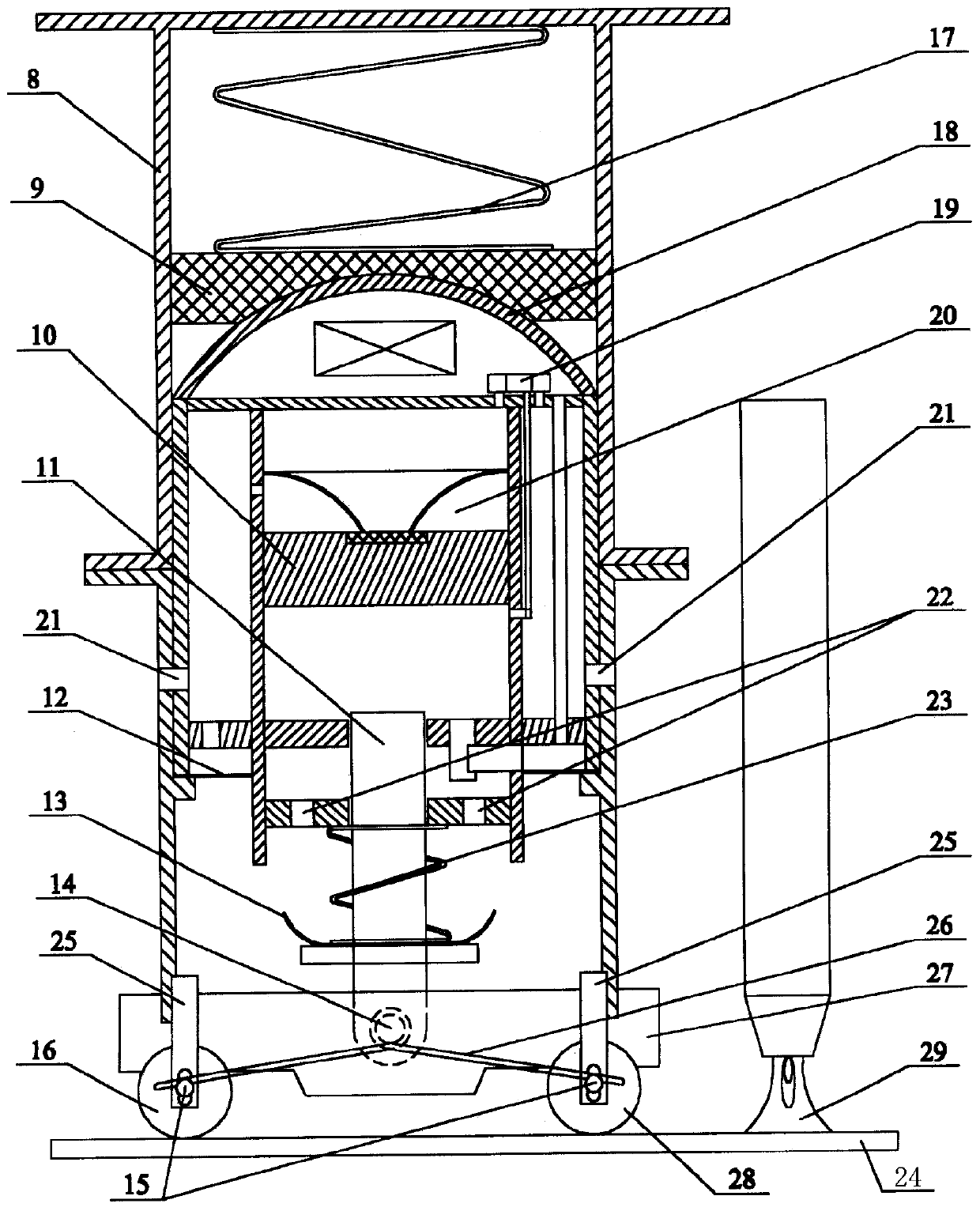

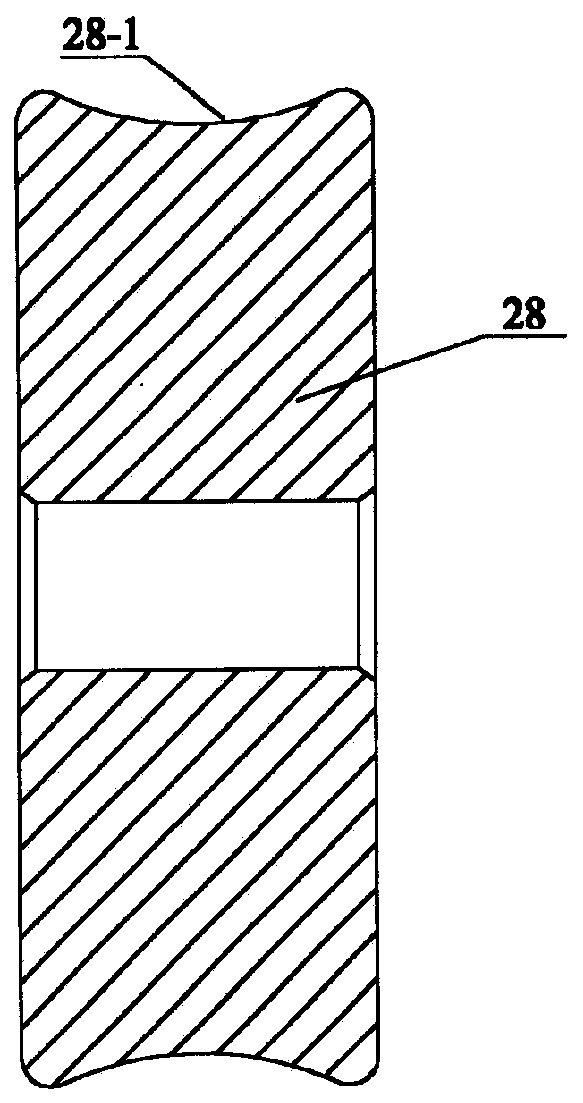

[0056] An impact rolling machine head for welding, which includes a housing 8, a shock absorber 9, a piston 10, an impact rod 11, an upper fairing 12, a lower fairing 13, a pin shaft 14, a wheel shaft 15, a rolling cam 16, Damping spring 17, air hammer 18, exhaust control valve 19, cylinder 20, air vent 21 on the cylinder, air vent 22, strong pressure spring 23, rolling wheel support bracket, mounting clip 25, torsion spring 26, Rolling wheel bearing 27, rolling concave wheel 28 form.

[0057] The air hammer 18 is fixed in the middle part of the housing 8, and the housing 8 on the top of the air hammer 18 is fixed with a shock absorber 9, and a shock absorber spring 17 is arranged between the upper part of the shock absorber 9 and the top cover of the housing 8, The bottom of air hammer 18 is fixed with cylinder 20, and the top of cylinder 20 is provided with exhaust control valve 19, and exhaust control valve 19 is equivalent to reversing valve, and the inside of cylinder 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com