Dissimilar material composite welding method

A technology of composite welding and dissimilar materials, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of difficulty in crystallization and element diffusion, inability to obtain high-strength joints, and reduced joint strength, reducing the interface effect of temperature difference, final reliable connection, and improved solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

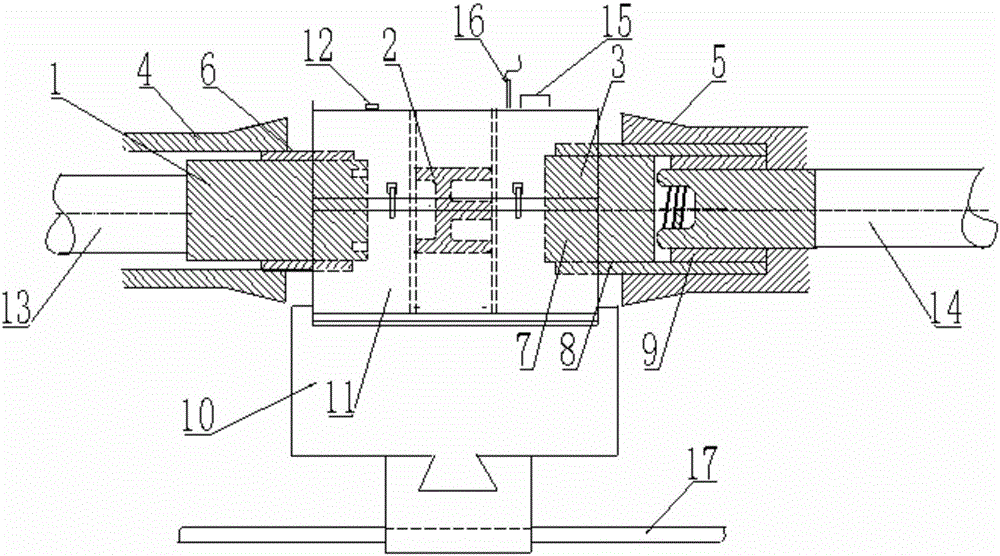

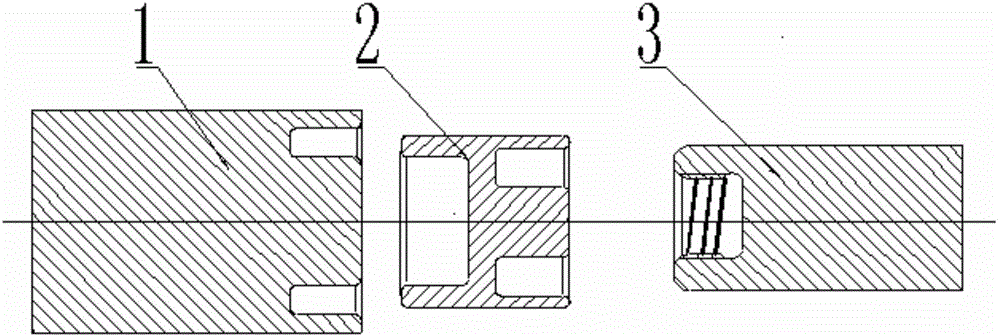

[0101] Embodiment 1: In this embodiment: the part a to be welded is made of steel, the part c to be welded is made of a TiAl-based alloy, and the intermediate transition layer: the part b to be welded is made of a nickel-based alloy; the pressing rod is graphite Great.

[0102] The method for composite welding of dissimilar materials in this embodiment includes the following steps:

[0103] (1) Cleaning before welding: Grinding with metallographic sandpaper, ultrasonically cleaning the welding surface of the piece to be welded a1, the welding surface of the piece to be welded b2 and the surface of the piece to be welded c3;

[0104] (2) Clamping of the rotating end: Put the ejector rod 13 of the rotating end into the rotating clamping end, adjust the length of the ejector rod 13 of the rotating end to make it close to the step of the inner hole of the main shaft of the rotating end, and then make the non-welding surface of the workpiece a1 to be welded close Rotate the push r...

Embodiment 2

[0114] Embodiment 2: In this embodiment: the part a to be welded is made of 20 steel, the part c to be welded is made of TC4 titanium alloy, and the intermediate transition layer: the part b to be welded (thickness of the solid part is 3mm) is made of T2 red copper ; The top pressure rod is a graphite rod.

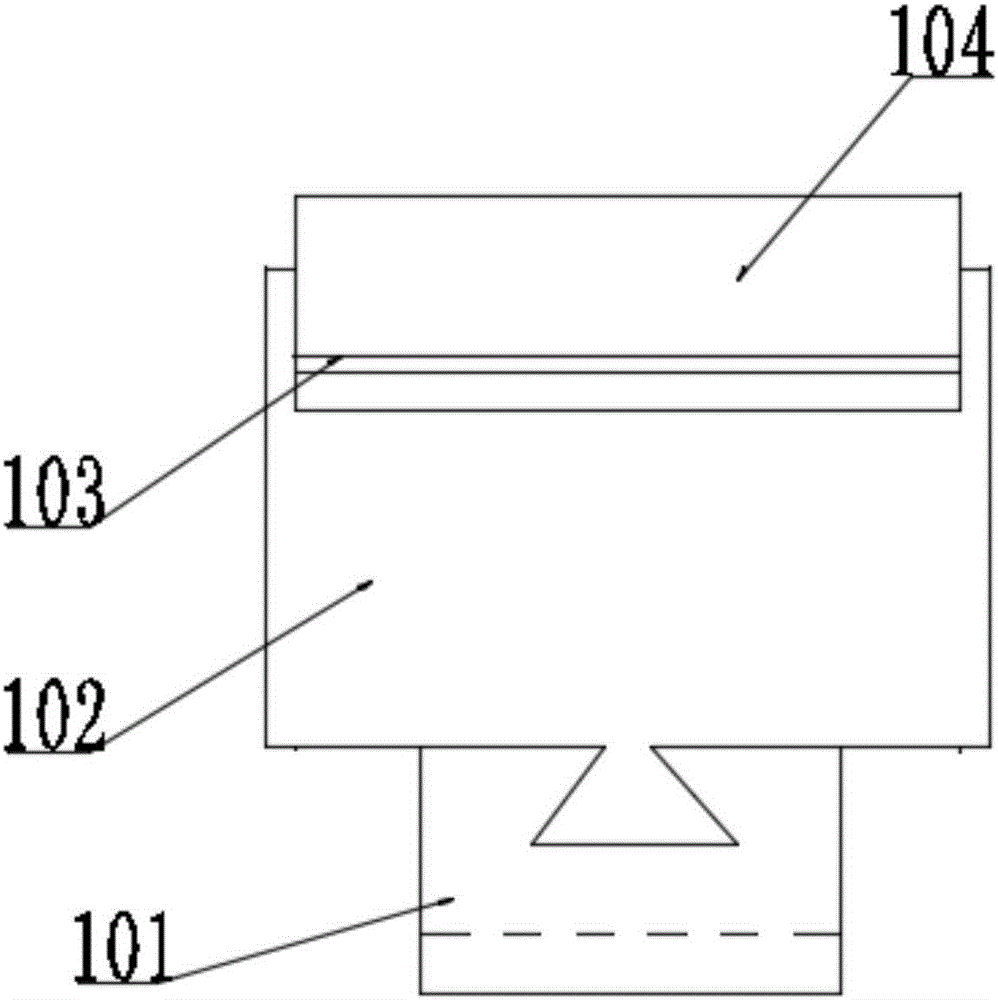

[0115] (4) Installation and preloading of the intermediate transition layer: place the piece to be welded b2 close to the inner boss of the 11 heater, slide the 10 intermediate support frame axially, so that the welding surface of the piece to be welded a and the piece to be welded Contact the front end of b2, then move the welding machine slide table, apply a top-tightening pre-pressure of 1.5MPa, make the graphite rod 7 contact with the piece to be welded b2, and push the piece to be welded b2 to slightly contact with the piece to be welded a1, close the 11 heaters, buckle the buckle;

[0116] (4) Diffusion connection of the intermediate transition layer: set the pre-pr...

Embodiment 3

[0120] Embodiment Three: In this embodiment: the part to be welded a is made of 40 steel, the part c to be welded is made of 93W tungsten alloy; the intermediate transition layer: the part b to be welded is made of pure vanadium and pure nickel foil; the top The pressure rod is a graphite rod.

[0121] For piece b to be welded, nickel is in the front and vanadium is in the back, that is, nickel and steel are welded, vanadium and tungsten alloy are friction welded, and nickel and vanadium are diffused and joined. Nickel foil 0.03mm, vanadium solid part thickness 1.5mm

[0122] (4) Diffusion connection of the intermediate transition layer: set the pre-pressure to 5MPa, the welding pressure to 56MPa, the heating temperature to 1050°C, the heating rate from 0°C to 700°C is controlled at 8°C / mim, and the temperature rise from 700°C to 1050°C The rate is controlled at 5°C / mim, the temperature is kept for 80 minutes, and the furnace is cooled; the argon gas is introduced to start we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com