Combined trigger type friction stir plug brazing repair welding method and its welding tool

A friction stir, triggering technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as cracks, incomplete keyhole filling, and reduced strength of repair welding joints, achieving high strength and improving repair welding. The effect of seam quality and workpiece deformation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

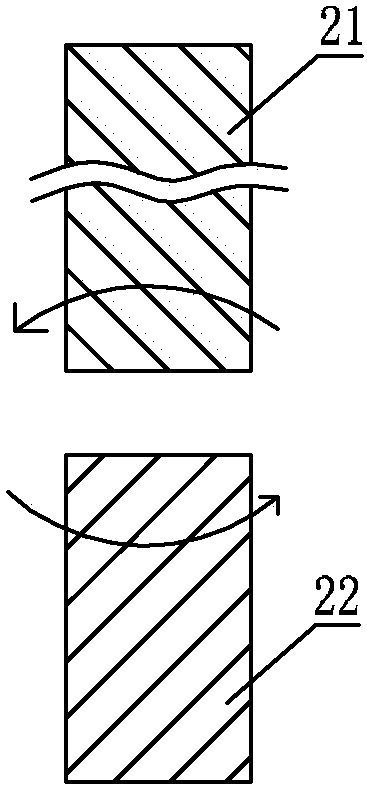

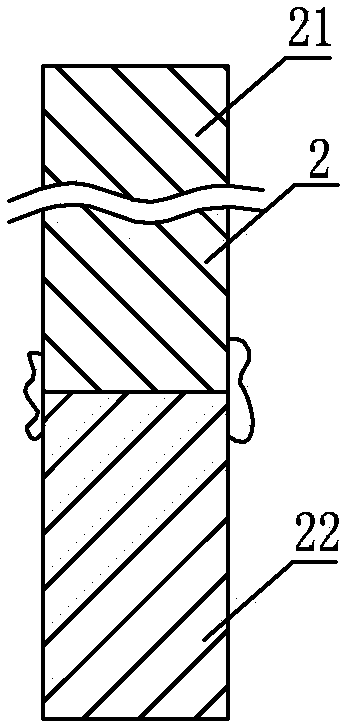

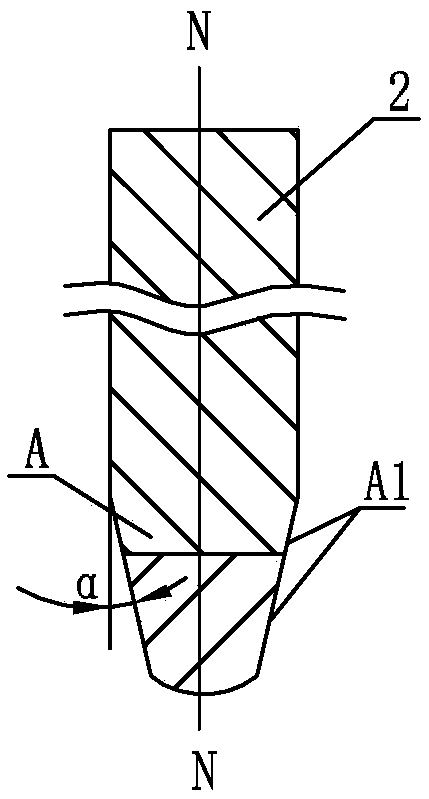

[0024] Step 1, preparing the stirring body 2: the stirring body 2 is divided into upper and lower parts, the upper part of the stirring body adopts a metal rod 21, and the lower part of the stirring body adopts a zinc-aluminum bar material 22, see figure 1 , the material of the metal rod 21 is the same as that of the parts to be repaired, and the metal rod 21 and the zinc-aluminum rod 22 are set up and down and connected together, see figure 2 , the metal on the surface of the stirring body 2 is removed by mechanical processing, and the lower end of the stirring body 2 is processed into a truncated conical shape A, the bottom of the truncated conical shape A is a spherical surface, and the truncated conical shape A is the stirring needle A, see image 3 , the upper part of the ...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 2 This embodiment is described. In this embodiment, the metal rod 21 and the zinc-aluminum rod 22 are welded together by friction welding in the first step. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 4 Describe this embodiment, this embodiment is that in step 1, the metal rod 21 and the zinc-aluminum rod 22 are connected together by means of threaded connection, wherein the lower end surface of the metal rod 21 is an internal thread, and the upper end surface of the zinc-aluminum rod 22 is external thread. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com