A Method for Inducing Super Graphene Network Structure Using Femtosecond Pulsed Laser

A technology of laser induction and network structure, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as complex processes, and achieve the effect of simple process and good joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

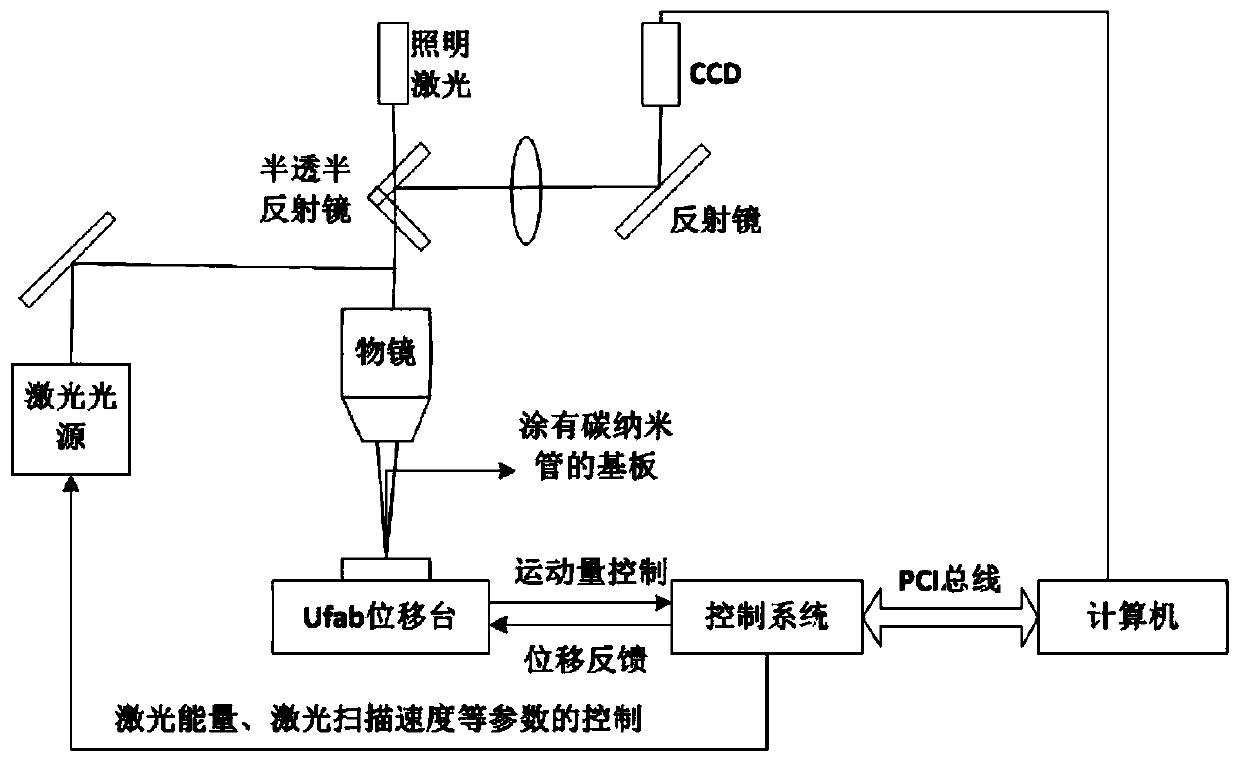

[0017] Embodiment 1, a kind of method utilizing femtosecond pulsed laser to induce super graphene network structure comprises the following steps:

[0018] 1) Non-covalently modified MWCNTs: prepare 50 mL of 1% sodium dodecyl sulfate SDS aqueous solution in a beaker, weigh 100 mg MWCNTs and transfer them to the sodium dodecyl sulfate SDS aqueous solution, and first use a tank-type ultrasonic cleaner to sonicate 20 minutes, and then use the angle ultrasonic machine to conduct ultrasound, the specific parameters of the angle type ultrasonic machine: power 60W, ultrasonic time 1 second, interval time 1 second, ultrasonic time 6 hours, to obtain non-covalently modified MWCNTs in the water environment;

[0019] 2) Construction of the inductive substrate: the non-covalently modified MWCNTs in the aqueous environment were deposited onto the silica SiO by a spin-coating process. 2 surface of the substrate, and then move the spin-coated substrate to a heating station and heat it at 60°...

Embodiment 2

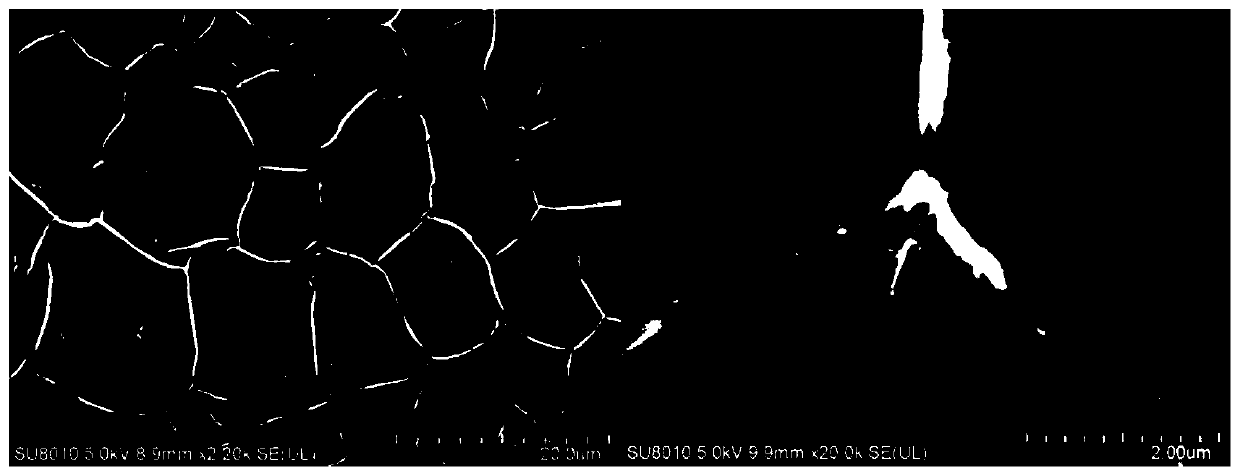

[0022] Embodiment 2: the embodiment 1 step 3) is adjusted to: the laser energy of 70mW is with the laser rate scanning induction substrate of 25mm / s, and other step order and parameter are constant, can obtain the smooth super graphene network structure of joint, refer to image 3 , the super graphene network structure is basically complete.

Embodiment 3

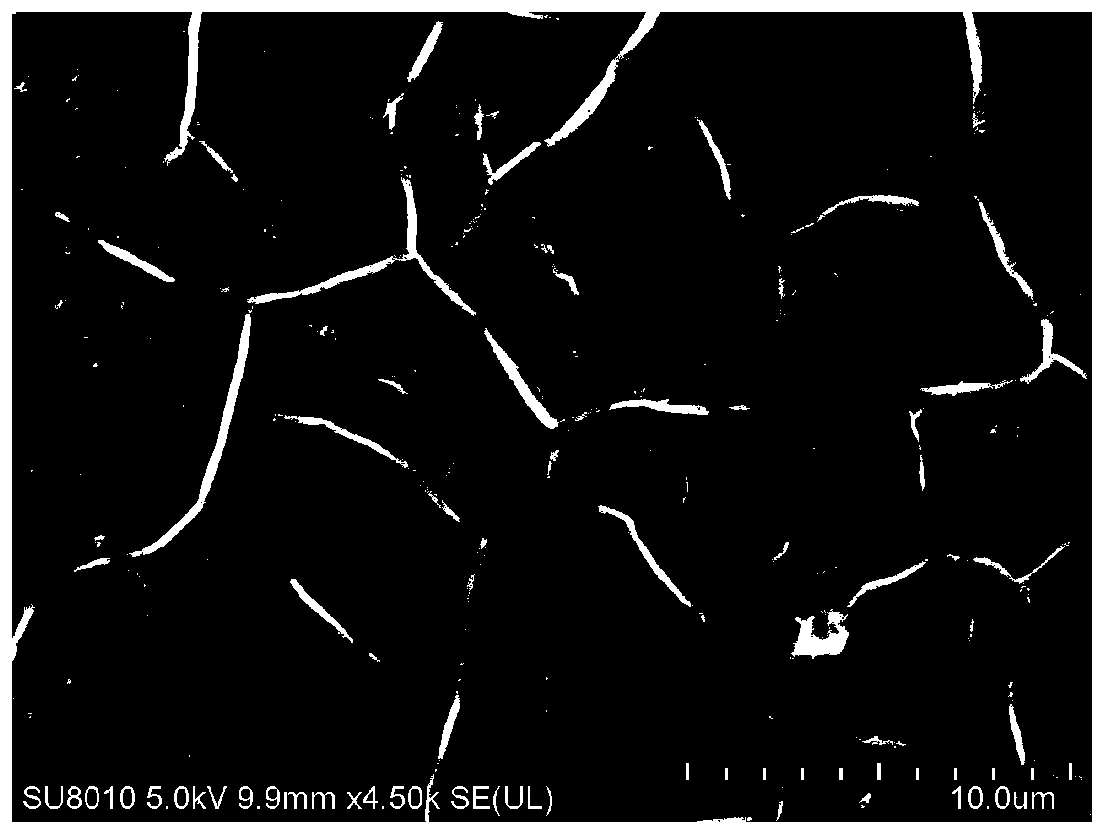

[0023] Embodiment 3: the embodiment 1 step 3) is adjusted to: the laser energy of 60mW is with the laser rate scanning induction substrate of 20mm / s, and other step order and parameter are constant, can obtain the smooth super graphene network structure of joint, refer to Figure 4 , the super graphene network structure is basically complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com