Laser auxiliary hot-pressure welding device and welding method for connecting titanium / aluminum dissimilar materials

A dissimilar material and laser-assisted technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as unsatisfactory results, no one specialized in equipment design and production, high cost of diffusion welding, etc., to achieve low cost , good joint quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

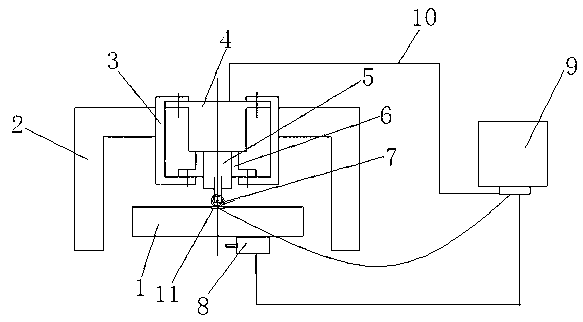

[0009] Such as figure 1 As shown, the present invention is achieved in this way, the pressure welding device includes a workbench 1, a support 2, a fixed frame 3, a cylinder 4, a guide rod 5, a guide sleeve 6, a roller 7, a stepping motor 8, a microprocessor 9, The control line 10 and the pressure sensor 11 are characterized in that the cylinder 4 and the guide sleeve 6 are connected to the bracket 2 through the fixing frame 3, the upper end of the guide sleeve 6 is connected to the bottom of the cylinder 4, and the guide rod 5 located inside the guide sleeve 6 is also connected to the bottom of the cylinder 4. Connected to the bottom of the cylinder 4, the bottom of the guide rod 5 is connected with a roller 7, the workbench 1 directly below the roller 7 is provided with a pressure sensor 11, the side of the workbench 1 is connected with a stepper motor 8, the pressure sensor 11, Both the stepper motor 8 and the cylinder 4 are connected with the microprocessor 9 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com