Triaxial fluxgate sensor

A fluxgate sensor and door sensor technology, applied in the field of micro-electromechanical systems, can solve problems such as poor performance of fluxgate sensors and sensor damage, and achieve the effects of high consistency, shortened size, and reduced application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

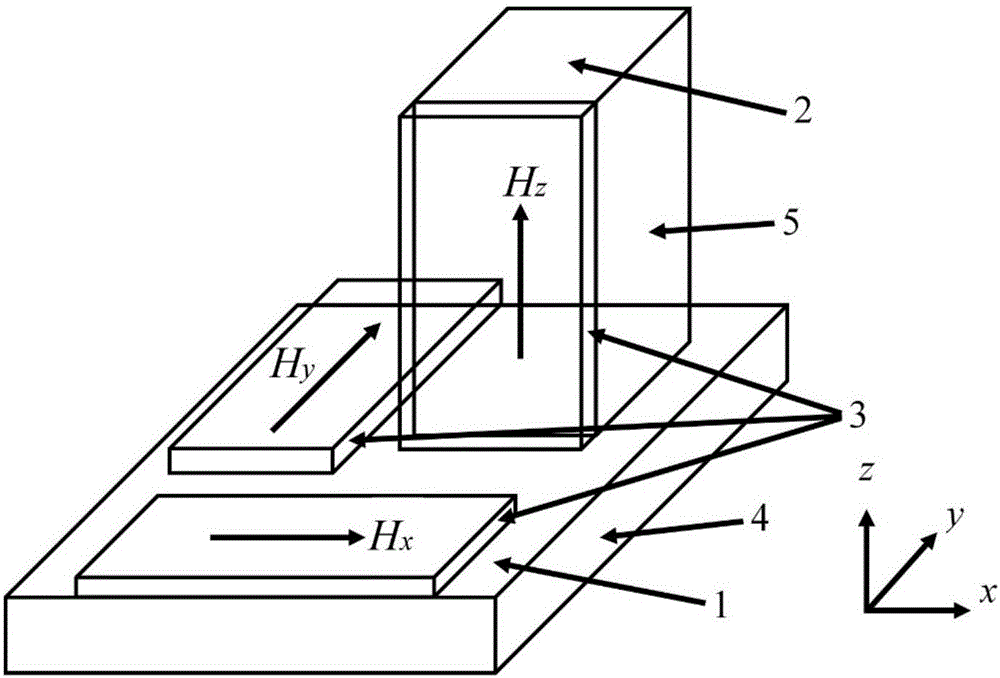

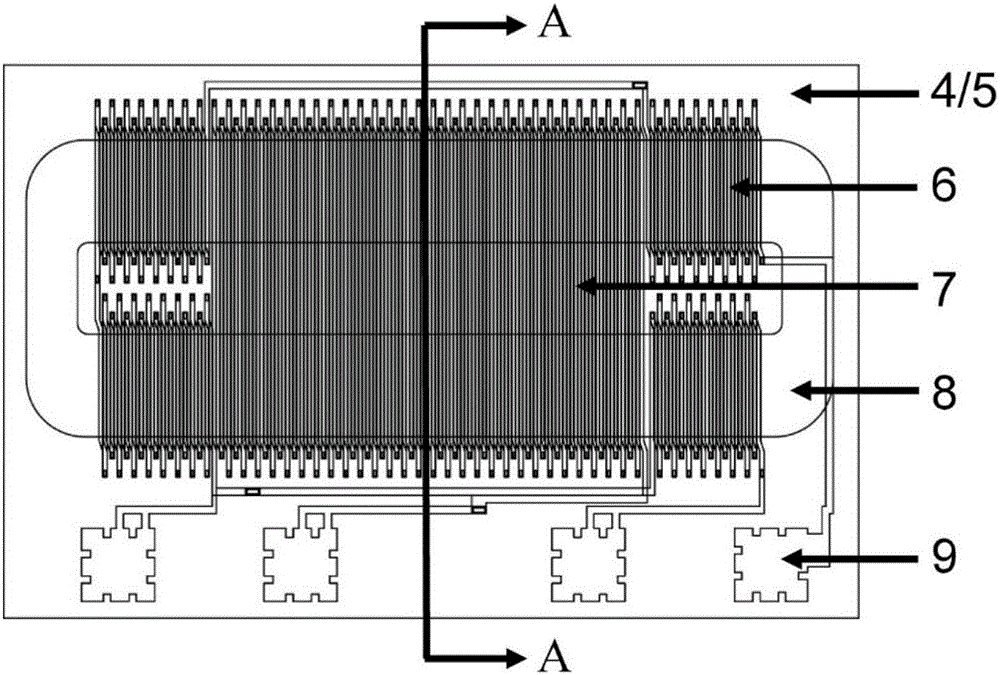

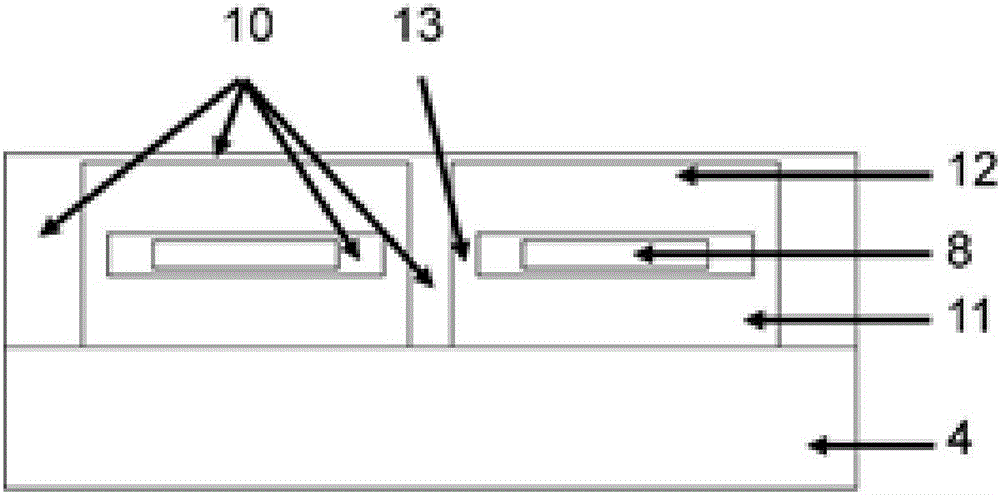

[0030] Such as Figure 1-4As shown, the quasi-integrated three-axis fluxgate sensor of the present invention includes an x-y biaxial planar fluxgate sensor chip 1 and a z-axis uniaxial planar fluxgate sensor chip 2; wherein the x-y biaxial planar fluxgate sensor chip Chip 1 includes two orthogonally distributed single-axis planar fluxgate sensor units 3 of 10mm*5mm*0.2mm in size on the same silicon substrate 4 with a thickness of 0.5mm, and the single-axis planar fluxgate sensor unit Contains a silicon substrate 4, an excitation coil 6, a detection coil 7, a magnetic core 8, an electrode 9 and a polyimide film 10. The z-axis uniaxial planar fluxgate sensor chip 2 with a size of 10mm*5mm*3.2mm and x-y The uniaxial planar fluxgate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com