Pencil clamping mechanism of pencil sharpener

A pencil sharpener and pencil clamping technology, which can be used in sharpening devices, printing, office supplies, etc., can solve the problems of decreased stability of pen clamping and pencils that cannot be cut normally, and achieve the effect of improving stability and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

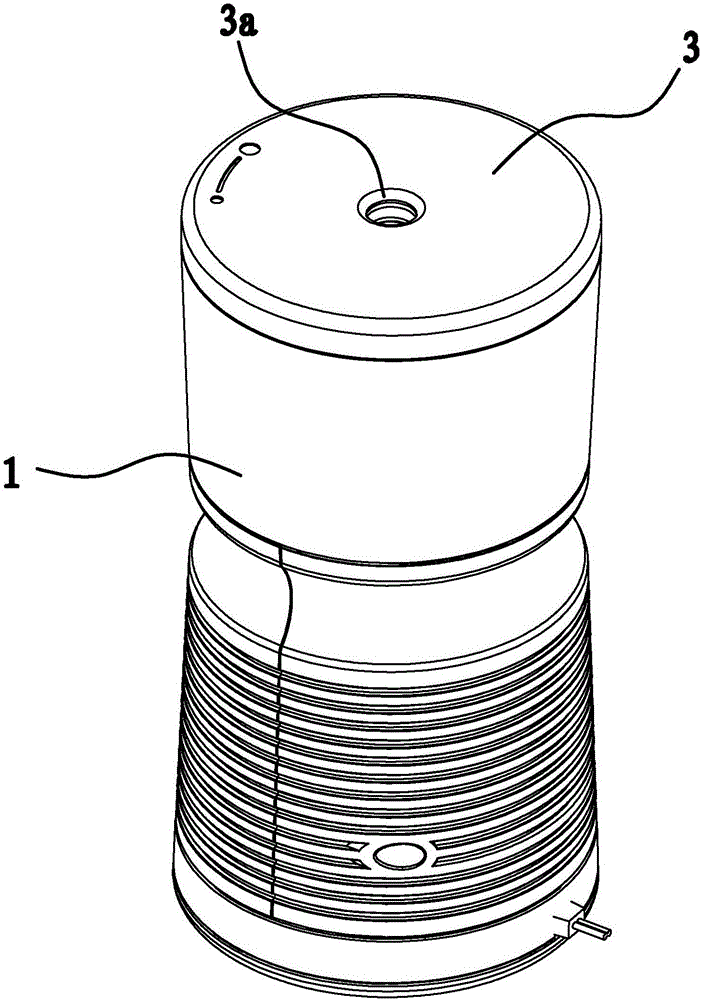

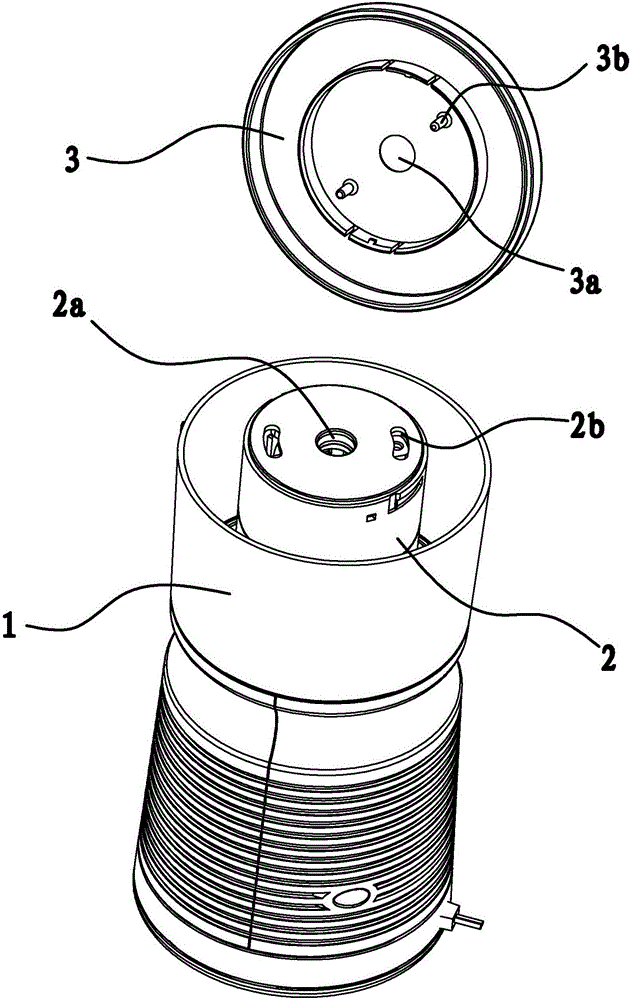

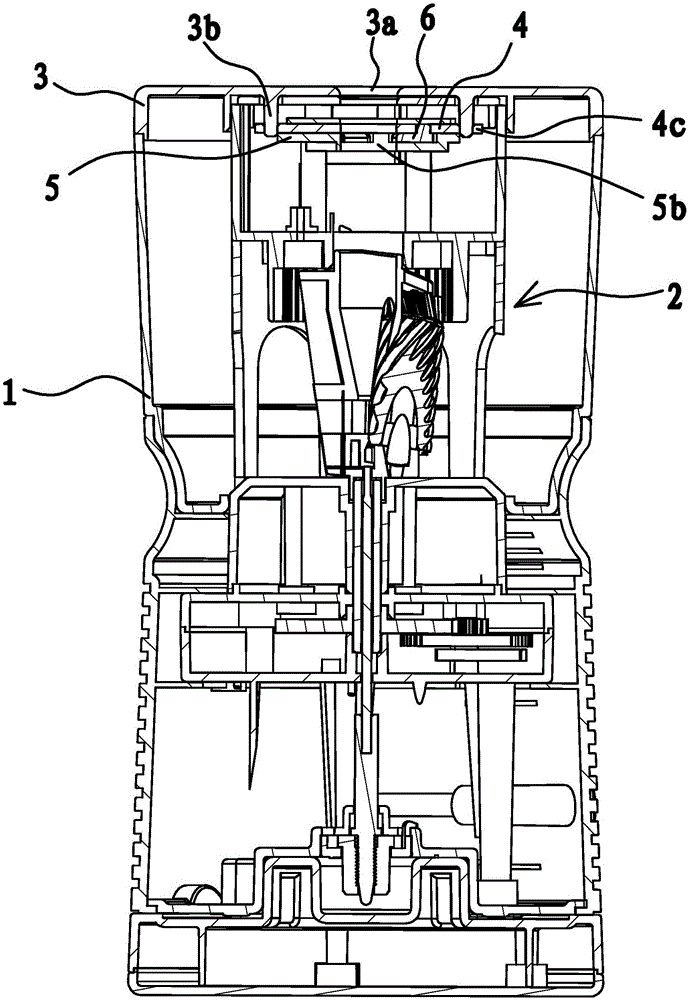

[0036] figure 1 , figure 2 with image 3 Shown, a kind of pen clamp mechanism of pencil sharpener, pencil sharpener comprises casing 1 and is arranged on the pencil sharpener core 2 in casing 1, and this pencil clamp mechanism comprises screw cap 3, rotating disc 4, chuck 5 and A plurality of pen holders 6, the upper end of the casing 1 is open, the rotary cover 3 is connected to the top of the casing 1 and can rotate relative to the casing 1, the center of the rotary cover 3 is provided with a first pen entry hole 3a, the rotating disk 4 and The chucks 5 are all arranged in the pencil sharpener movement 2 , and each pen clamping block 6 is located between the rotating disk 4 and the chuck 5 .

[0037] Such as figure 2 with image 3 As shown, the center of the upper end face of the pencil sharpening core 2 is provided with a second pen inlet 2a, and the second pen inlet 2a is opposite to the first pen inlet 3a. The bottom of the screw cap 3 has a number of protruding co...

Embodiment 2

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that in this embodiment, positioning holes are provided on the outer peripheral side of the turntable 4, and the elastic positioning members are springs and steel balls arranged in the positioning holes. The positioning grooves 5a2 are spherical in shape, and when the positioning holes are opposite to the positioning grooves 5a2, some steel balls are inserted into the positioning grooves 5a2 under the elastic force of the spring.

[0047] During the rotation of the turntable 4, the steel ball is pushed against the inner wall of the annular protrusion 5a under the elastic force of the spring, but because the steel ball is spherical, the steel ball is in line contact with the inner wall of the annular protrusion 5a, so although the steel ball is pushed against the inner wall of the annular protrusion 5a The inner wall of the annular protrusion 5a does not affect the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com