A kind of 135ksi grade titanium alloy, titanium alloy drill pipe and preparation method thereof

A titanium alloy and drill pipe technology, which is applied to drill pipe, drilling equipment, drill pipe, etc., can solve the problems of high cost and low yield strength, and achieve the effects of low cost, simple proportioning and improved plastic deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

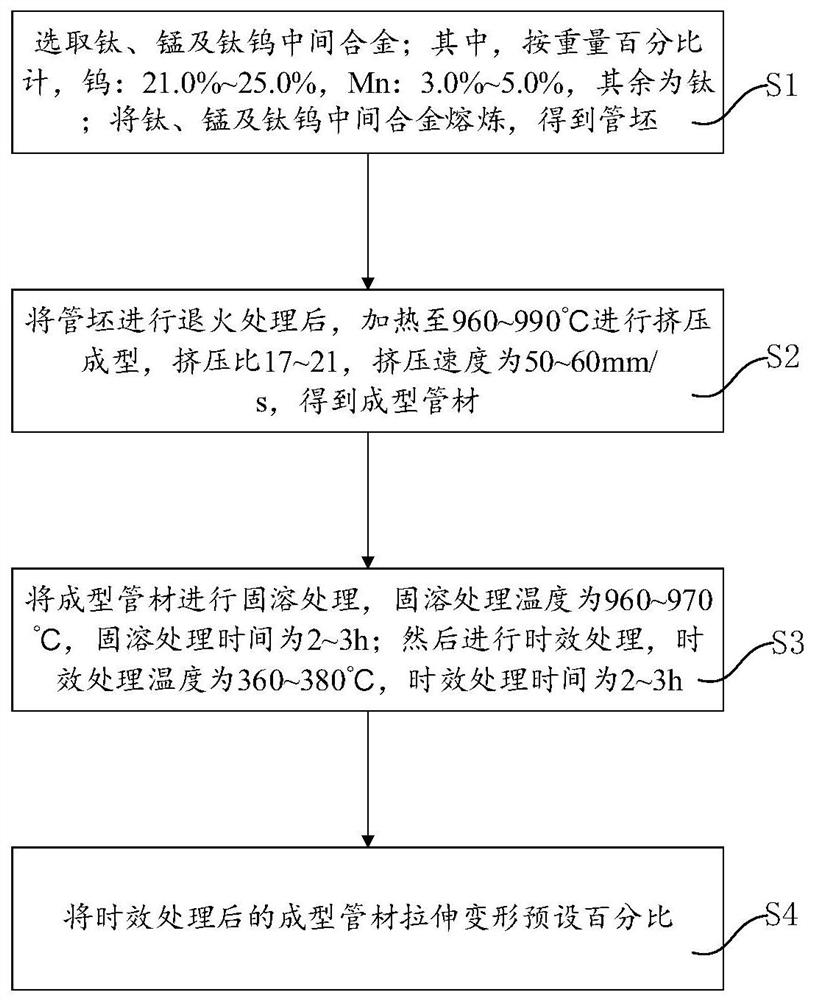

[0038] see figure 1, the preparation method of the 135ksi grade titanium alloy drill pipe of the present invention, specifically 135ksi grade ω+β dual-phase 135ksi grade titanium alloy drill pipe and its preparation method, this preparation method can effectively solve the low strength of the existing 135ksi grade titanium alloy drill pipe , There are no ultra-high steel grade pipes above 135Ksi, the production process is complex, the processing performance requirements are high, the cost is high, and it is difficult to balance strength and plastic toughness at the same time. Concrete, the preparation method of this 135ksi grade titanium alloy drill rod comprises the following steps:

[0039] S1: Select titanium, manganese and titanium-tungsten master alloy; wherein, by weight percentage, tungsten: 21.0% to 25.0%, Mn: 3.0% to 5.0%, and the rest is titanium and unavoidable impurities; titanium, manganese and titanium The tungsten master alloy is smelted to obtain the tube blan...

Embodiment 1

[0051] 1. Ingredients: According to the composition of Ti-21.0wt%W-3.0wt%Mn alloy, zero-grade sponge Ti, pure Mn and Ti-31.0wt%W master alloy are prepared respectively; the purity of the above metals is ≥99.99%.

[0052] 2. Melting: Vacuum suspension casting method is used to melt titanium, manganese and titanium-tungsten master alloy. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the furnace temperature is 1600°C, and the tube blank is obtained. After the tube blank is fully cooled, the tube blank is peeled to remove the oxide layer on the surface.

[0053] 3. Annealing treatment: the tube billet is annealed in a box-type resistance furnace, the annealing temperature is 870°C, the holding time is 2h, and the cooling method is air cooling.

[0054] 4. Extrusion treatment: Extrude the annealed tube billet at an extrusion temperature of 960° C., an extrusion ratio of 17, and an extrusion speed of 50 mm / s to obtain a formed pipe.

[0055] 5. Solution ...

Embodiment 2

[0058] 1. Ingredients: According to the composition of Ti-23.0wt%W-4.0wt%Mn alloy, zero-grade sponge Ti, pure Mn and Ti-31.0wt%W master alloy are prepared respectively; the purity of the above metals is ≥99.99%.

[0059] 2. Melting: Vacuum suspension casting method is used to melt titanium, manganese and titanium-tungsten master alloy. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the furnace temperature is 1600°C, and the tube blank is obtained. After the tube blank is fully cooled, the tube blank is peeled to remove the oxide layer on the surface.

[0060] 3. Annealing treatment: the tube billet is annealed in a box-type resistance furnace, the annealing temperature is 880°C, the holding time is 2.6h, and the cooling method is air cooling.

[0061] 4. Extrusion treatment: Extrude the annealed tube billet at an extrusion temperature of 970° C., an extrusion ratio of 19, and an extrusion speed of 56 mm / s to obtain a formed pipe.

[0062] 5. Solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com