Omega phase change induced reinforced and toughened metastable beta type titanium alloy, pipe and manufacturing method

A technology of strengthening and toughening and phase change induction, which is applied in the direction of manufacturing tools, pipes, rigid pipes, etc., can solve the problems of easy generation of toxic hexavalent Cr ions, etc., to achieve improved plastic deformation ability, easy deformation processing, and improved yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

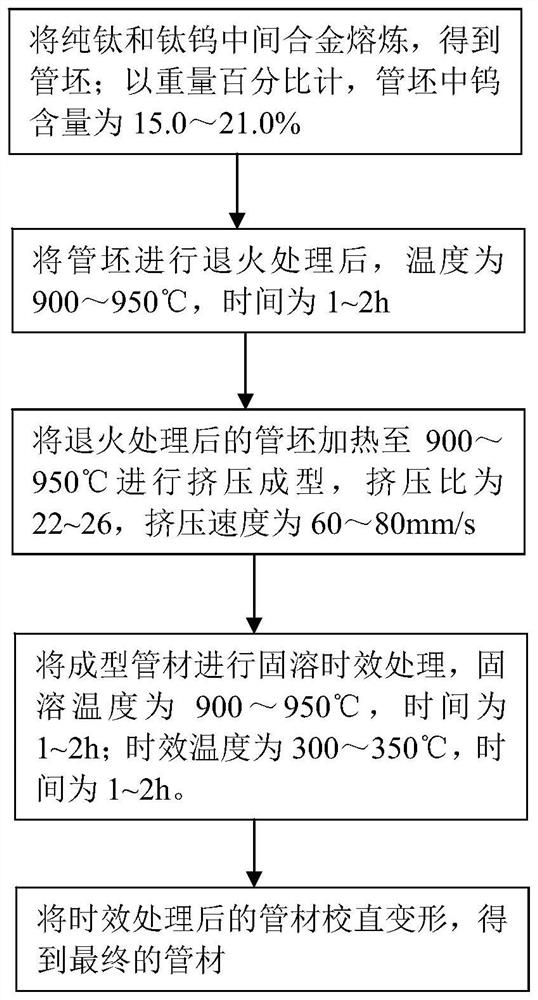

Method used

Image

Examples

Embodiment 1

[0036] 1. Ingredients: according to the composition of Ti-15.0wt%W alloy, prepare zero-grade sponge Ti and Ti-31.0wt%W master alloy respectively; the purity of the metal is ≥99.99%;

[0037] 2. Melting: Vacuum suspension casting method is adopted. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the furnace temperature is 1600 ° C, and the alloy ingot is obtained; after sufficient cooling, the ingot is peeled to remove the oxide layer on the surface;

[0038] 3. Annealing treatment: Annealing treatment in a box-type resistance furnace, the annealing temperature is 900°C, the holding time is 1h, and air cooling;

[0039] 4. Extrusion treatment: extrusion temperature: 900°C, extrusion ratio 22, extrusion speed 80mm / s;

[0040] 5. Solution aging treatment: the solution temperature is 900°C and the time is 1h; the aging temperature is 300°C and the time is 1h.

[0041] 6. The straightening deformation of the pipe is 3%, and the final product is finished. ...

Embodiment 2

[0043] 1. Ingredients: according to the composition of Ti-18.0wt%W alloy, prepare zero-grade sponge Ti and Ti-31.0wt%W master alloy respectively; the purity of the metal is ≥99.99%;

[0044] 2. Melting: Vacuum suspension casting method is adopted. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the furnace temperature is 1600 ° C, and the alloy ingot is obtained; after sufficient cooling, the ingot is peeled to remove the oxide layer on the surface;

[0045] 3. Annealing treatment: Annealing treatment in a box-type resistance furnace, the annealing temperature is 920°C, the holding time is 1.5h, and air cooling;

[0046] 4. Extrusion treatment: extrusion temperature: 940°C, extrusion ratio 24, extrusion speed 70mm / s;

[0047]5. Solution aging treatment: solution temperature is 930°C, time is 1h; aging temperature is 325°C, time is 1.5h;

[0048] 6. The straightening deformation of the pipe is 3%, and the final product is finished.

Embodiment 3

[0050] 1. Ingredients: according to the composition of Ti-21.0wt%W alloy, prepare zero-grade sponge Ti; Ti-31.0wt%W master alloy; the purity of the metal is ≥99.99%;

[0051] 2. Melting: Vacuum suspension casting method is adopted. During smelting, the vacuum degree in the furnace is controlled to be ≤10-2Pa, and the furnace temperature is 1600°C to obtain alloy ingots. After fully cooling, peel the ingot to remove the oxide layer on the surface;

[0052] 3. Annealing treatment: Annealing treatment is carried out in a box-type resistance furnace, the annealing temperature is 950 ° C, the holding time is 2 hours, and air cooling;

[0053] 4. Extrusion treatment: extrusion temperature: 950°C, extrusion ratio 26, extrusion speed 60mm / s;

[0054] 5. Solution aging treatment: solution temperature is 950°C, time is 1h; aging temperature is 350°C, time is 2h;

[0055] 6. The straightening deformation of the pipe is 3%, and the final product is finished.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com