Low-alloy high-strength structure steel hot-rolled H-shaped steel and production method thereof

A low-alloy high-strength, production method technology, applied in the direction of temperature control, etc., to achieve the effect of reducing the difficulty of production technology, simple component design, and improving low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

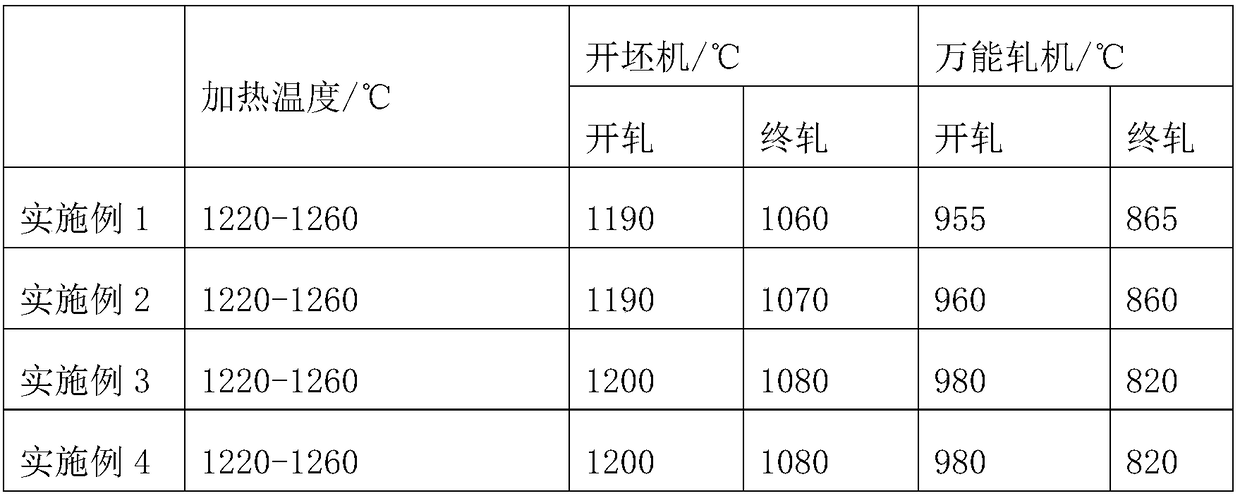

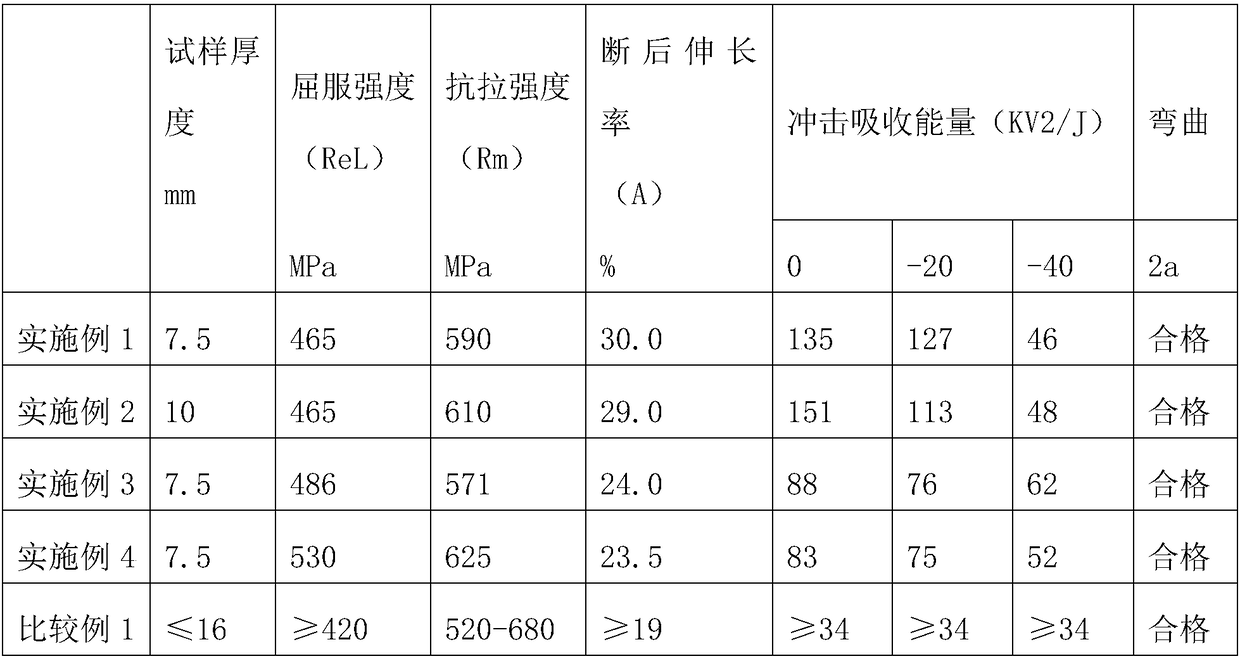

[0027] According to the steel composition requirements of the present invention, smelting in an 80t top-blown converter, refining in an LF ladle refining furnace, and using a continuous casting semi-protective casting process, the finished steel with the chemical composition described in Table 1 is obtained, and the section steel is rolled H300×150×6.5 ×9 specifications, the process parameters are shown in Table 6, and the mechanical properties are shown in Table 7.

[0028] The chemical composition (wt%) of table 1 embodiment 1 steel

[0029] C

Embodiment 2

[0031] According to the requirement of steel composition of the present invention, adopt 80t top-blowing converter to smelt, refine through LF ladle refining furnace, adopt continuous casting semi-protective casting process, obtain the finished steel with chemical composition as shown in the following table 2, section steel rolling H250×250×9 ×14 specifications, the process parameters are shown in Table 6, and the mechanical properties are shown in Table 7.

[0032] Chemical composition (wt%) of steel of table 2 embodiment 2

[0033] C

Embodiment 3

[0035] According to the composition requirements of the steel of the present invention, smelting in an 80t top-blown converter, refining in an LF ladle refining furnace, and using a continuous casting semi-protective casting process, the finished steel with the chemical composition as shown in Table 3 is obtained, and the section steel is rolled H450 × 150 × 6 ×9 specifications, rolling H-beam specifications, the process parameters are shown in Table 6, and the mechanical properties are shown in Table 7.

[0036] Chemical composition (wt%) of table 3 embodiment 3 steel

[0037] C

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com