High-strength gas-defended welding wire material

A welding wire and tough gas technology, which is applied in the field of all-position automatic welding material manufacturing, can solve the problem that the performance of the weld restricts the overall performance of the structure, and achieves the advantages of excellent all-position automatic welding manufacturability, reasonable composition design and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

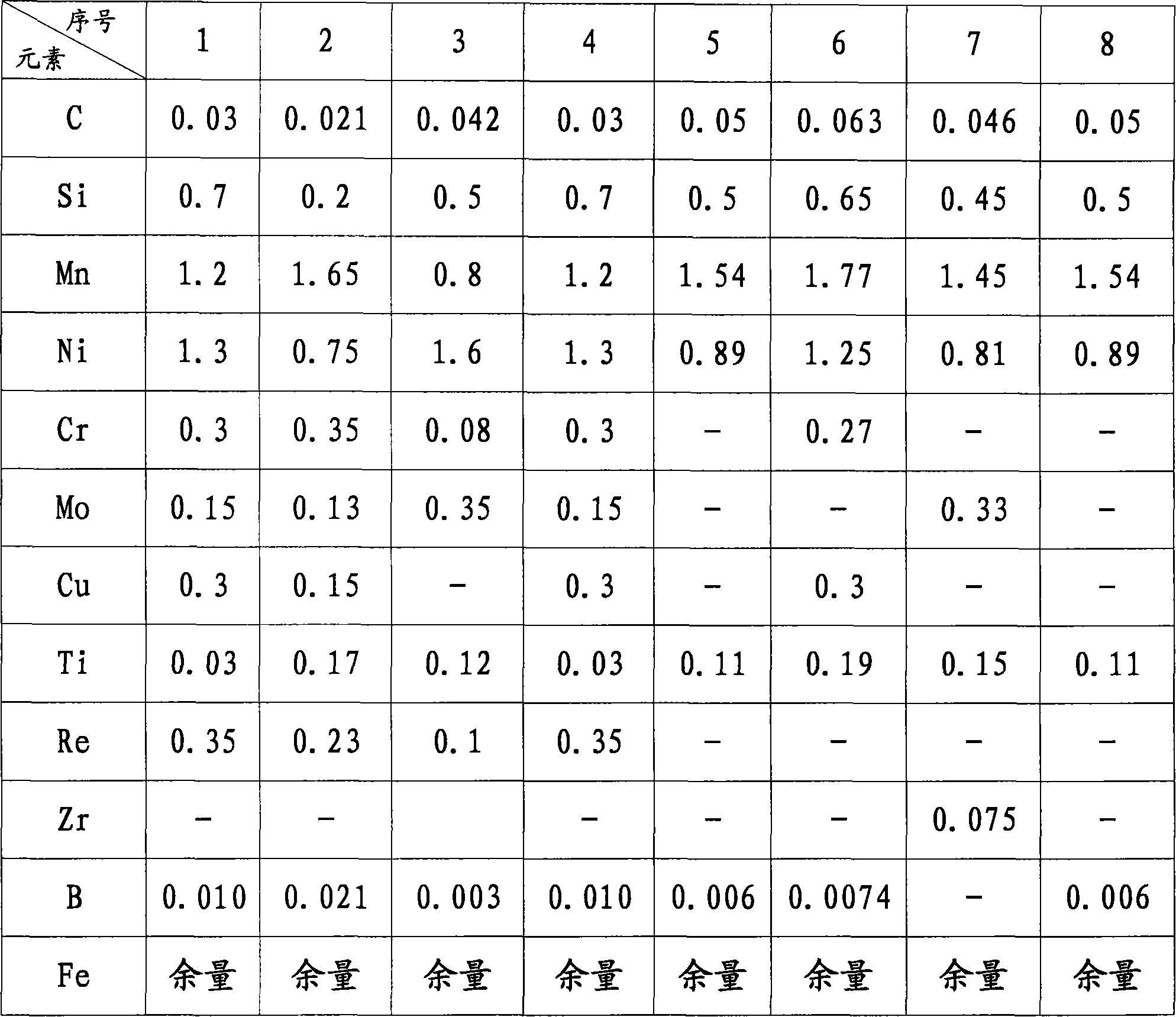

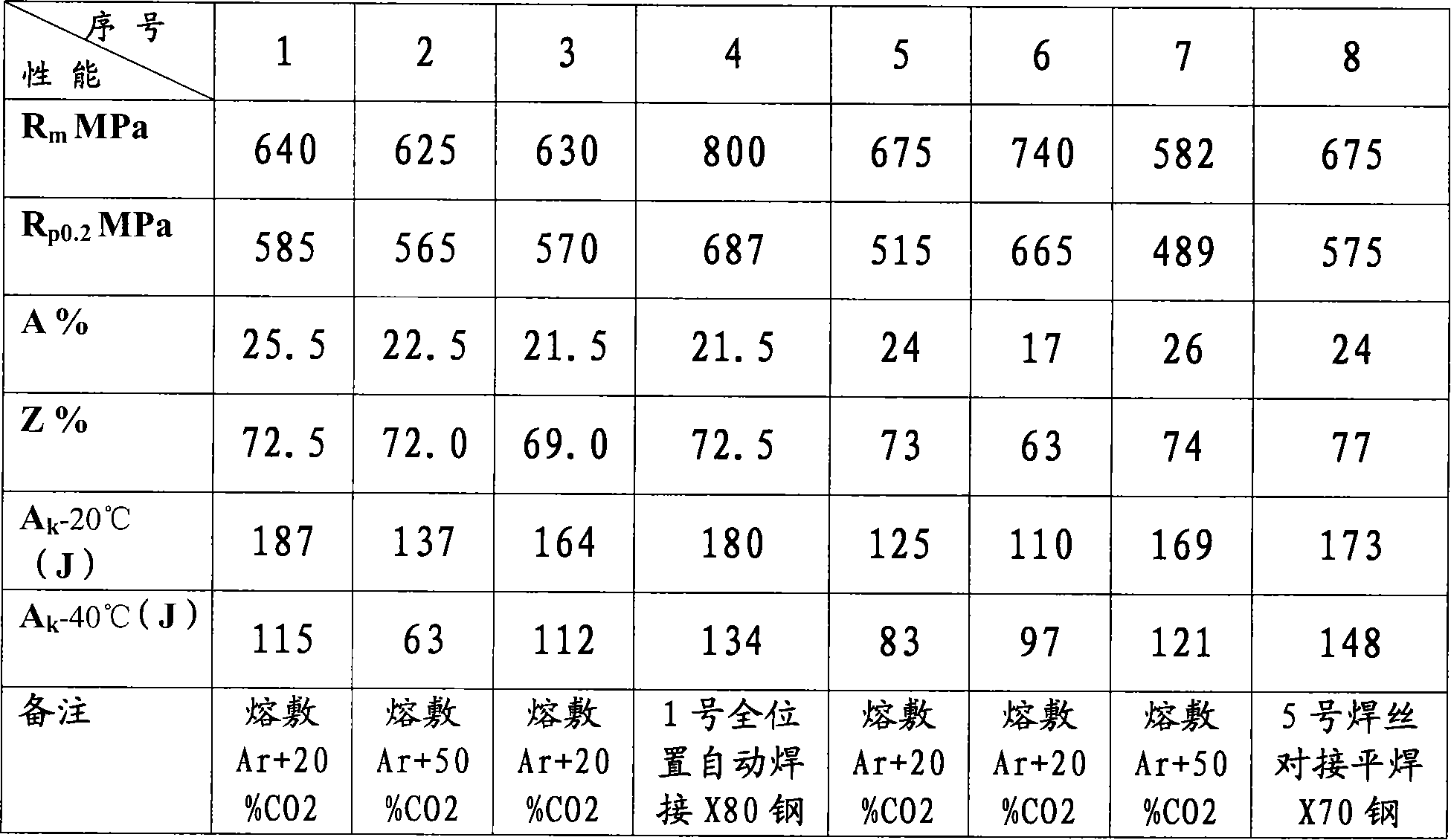

[0020] The embodiment of the present invention is the high-strength and toughness gas-shielded welding wire material composition range according to the above-mentioned design. We have implemented 7 groups of tests. Tough gas shielded welding wire material, and Group 4 are examples of prior art materials. The preparation of the embodiment of the present invention is to carry out the batching according to the test requirements, use the electric furnace for smelting, and then carry out rolling at 1050 ° C, the drawing of the welding wire or the copper plating are the processing methods of the prior art, and finally the gas used for the test comparison will be obtained. The size of the welding wire is copper-plated or non-copper-plated gas shielded wire material with a diameter of φ1.0mm. The embodiment in the present invention adopts deposited metal welding test (welding process parameter: welding wire diameter 1.2mm, welding current 220A, welding voltage 22V, line energy 14KJ / CM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com