High-tenacity low-alloy high-strength steel and quenched-tempered heat treatment method thereof

A low-alloy, high-strength, quenched and tempered heat treatment technology, applied in the field of low-alloy high-strength steel, can solve the problems that affect the safety of high-strength steel, high yield ratio, and no key consideration of yield ratio, etc., to achieve easy implementation, low yield Stronger than, less time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

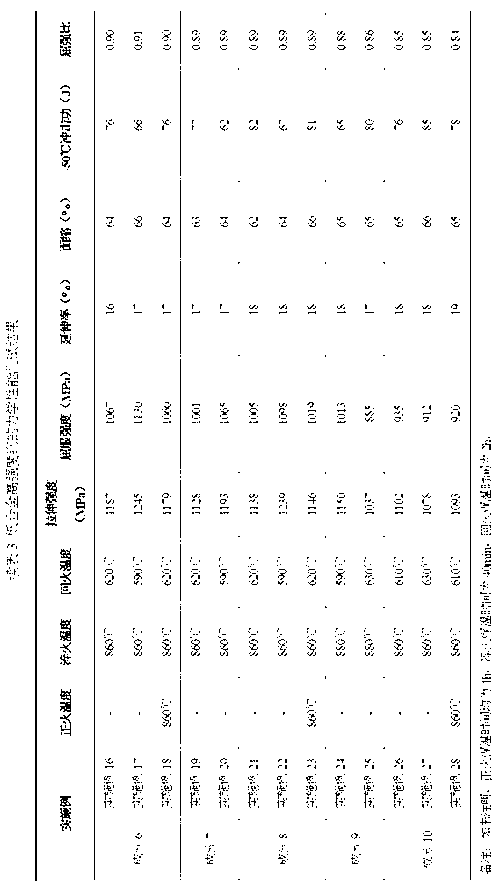

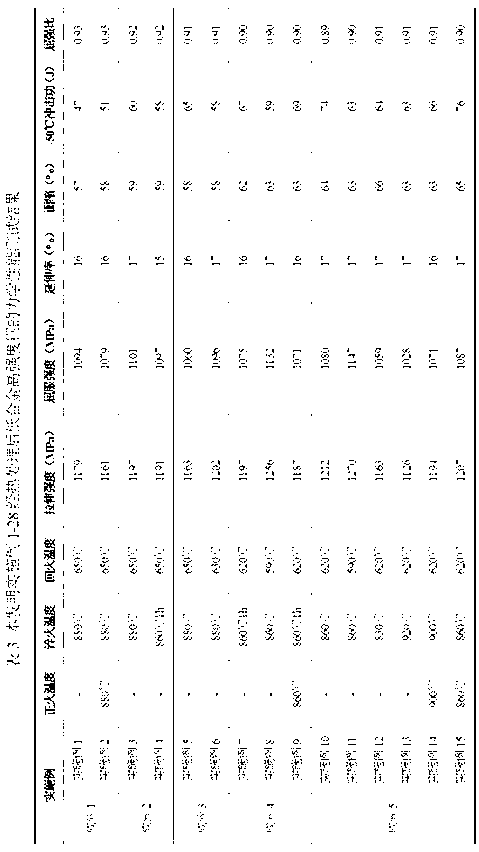

[0026] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

[0027] The low-alloy high-strength steel ingot smelted in the embodiment of the present invention is first forged at about 1100°C to ensure that the final forging temperature is not lower than 800°C, and then hot-rolled. The hot-rolling temperature is about 1100°C, and the thickness is rolled by 35mm. to about 12mm. Air cooling is used for normalizing, and oil quenching is used for quenching. At this time, care should be taken to prevent the oil temperature from rising too fast, which will affect the quenching effect. After the final tempering treatment, water cooling must be carried out to prevent temper brittleness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com