Hardenability-remaining high-strength low-temperature toughness spring steel

A low-temperature toughness, high-strength technology, applied in the field of alloy steel, to achieve the effect of improving strength and hardenability, and improving low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through embodiment.

[0016] Hardenability-guaranteed high-strength low-temperature ductile spring steel, the chemical composition is as follows according to weight percentage:

[0017] C: 0.56%-0.64%, Si: 1.40%-2.00%, Mn: 0.40%-0.80%, Cr: 0.70%-1.00%, Ni: 0.10%-0.40%, Cu≤0.25%, P≤0.025%, S≤0.025%, the rest is Fe and impurities; it has 880℃±20℃ quenching and 430±50℃ tempering tensile strength≥1750Mpa, normal temperature and -40℃ Aku2≥20J, end quenching test J20≥55HRC. The end quenching test is carried out according to GB / T225.

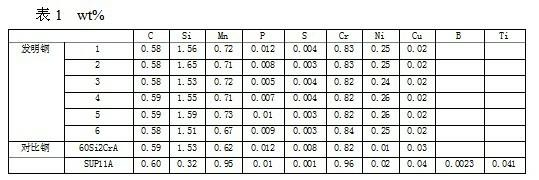

[0018] The chemical composition of each embodiment of the present invention and comparative steel is shown in Table 1. The steel of the present invention was rolled to φ50mm, and compared with the comparative steel.

[0019]

[0020] After the above-mentioned steel samples are prepared, heat treatment is carried out.

[0021] Tensile sample: GB / T1222 standard (φ11)

[0022] Impact sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com