Compound modification method for USY molecular sieve

A compound modification and molecular sieve technology, which is applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbon oil cracking, etc., can solve problems such as a large decrease in crystallinity, and achieve high crystallinity and high crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

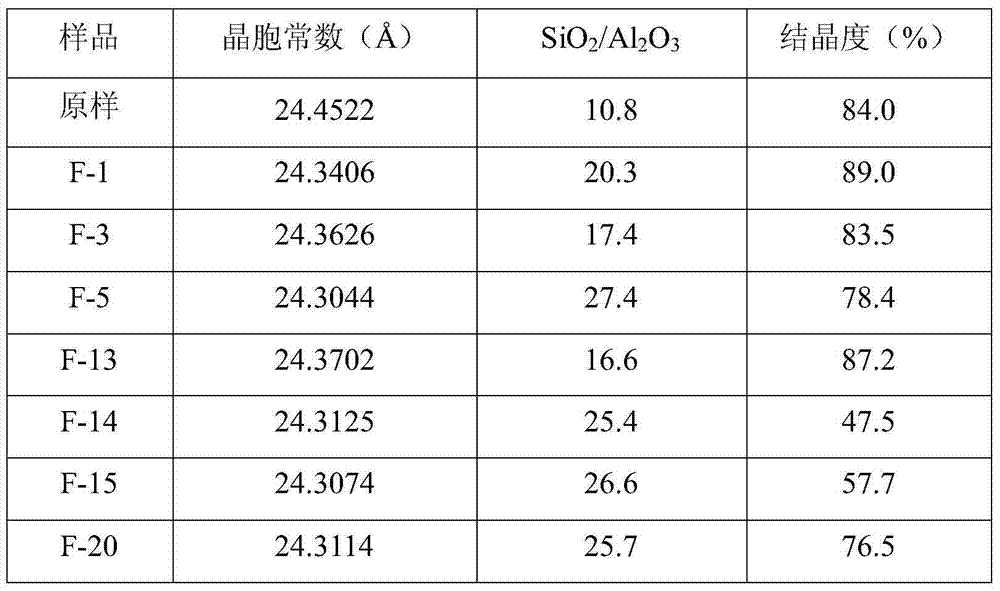

Embodiment 1

[0021] Prepare citric acid solutions with concentrations of 0.10mol / L, 0.15mol / L, 0.20mol / L and 0.25mol / L; prepare 0.10mol / L ammonium fluorosilicate solution;

[0022] Weigh 4 parts of industrial USY, 12g each, and add them to 250ml three-necked flasks respectively;

[0023] Add 60ml of citric acid solutions of different concentrations to each flask, stir, and heat up to 70°C;

[0024] When the temperature rises to 70°C, continuously add 60ml of ammonium fluorosilicate solution at a rate of 1ml / min;

[0025] The liquid-solid ratio is 10, and the volume ratio of the citric acid solution to the ammonium fluorosilicate solution is 1.0.

[0026] After addition, continue to react for 3h;

[0027] The obtained product was washed with deionized water until neutral, and dried at a constant temperature of 110° C. for 16 hours to obtain modified samples, which were marked as F-2, F-3, F-1, and F-4.

[0028] The results of the modified USY pore volume of each sample are shown in Table...

Embodiment 2

[0032] Prepare a citric acid solution with a concentration of 0.15mol / L; prepare a 0.10mol / L ammonium fluorosilicate solution;

[0033] Weigh 4 parts of industrial USY, 12g each, and add them to 250ml three-necked flasks respectively;

[0034] Add 60ml of citric acid solution to each flask, stir, and heat up to 70°C;

[0035] When the temperature rises to 70°C, add 60ml of ammonium fluorosilicate solution to each flask at a rate of 0.75ml / min, 1ml / min, 1.25ml / min and 1.5ml / min respectively;

[0036] The liquid-solid ratio is 10, and the volume ratio of the citric acid solution to the ammonium fluorosilicate solution is 1.0.

[0037] After addition, continue to react for 3h;

[0038] The obtained product was washed with deionized water until neutral, and dried at a constant temperature of 110° C. for 16 hours to obtain modified samples, labeled as F-8, F-3, F-9, and F-10.

[0039] The results of the modified USY pore volume of each sample are shown in Table 2.

[0040] Tabl...

Embodiment 3

[0044] Prepare a citric acid solution with a concentration of 0.15mol / L; prepare a 0.10mol / L ammonium fluorosilicate solution;

[0045] Weigh 4 parts of industrial USY, 12g each, and add them to 250ml three-necked flasks respectively;

[0046] Add 60ml of citric acid solution to each flask, stir, and heat up to 70°C;

[0047] When the temperature rises to 70°C, add 60ml of ammonium fluorosilicate solution to each flask at a rate of 1ml / min;

[0048] The liquid-solid ratio is 10, and the volume ratio of the citric acid solution to the ammonium fluorosilicate solution is 1.0.

[0049] After the feeding was completed, the reaction was continued, and the reaction times were 2h, 3h, 4h and 5h, respectively.

[0050] The obtained product was washed with deionized water until neutral, and dried at a constant temperature of 110° C. for 16 hours to obtain modified samples, labeled as F-11, F-3, F-12 and F-13.

[0051] The results of the modified USY pore volume of each sample are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com