Y-type molecular sieve with ultra-high mesoporous content and preparation method of Y-type molecular sieve

A technology of molecular sieve and mass ratio, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of skeleton collapse, limited application of Y-type molecular sieve, lack of effective connection, etc., and achieve rich secondary Pore structure, effect of improving thermal and hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

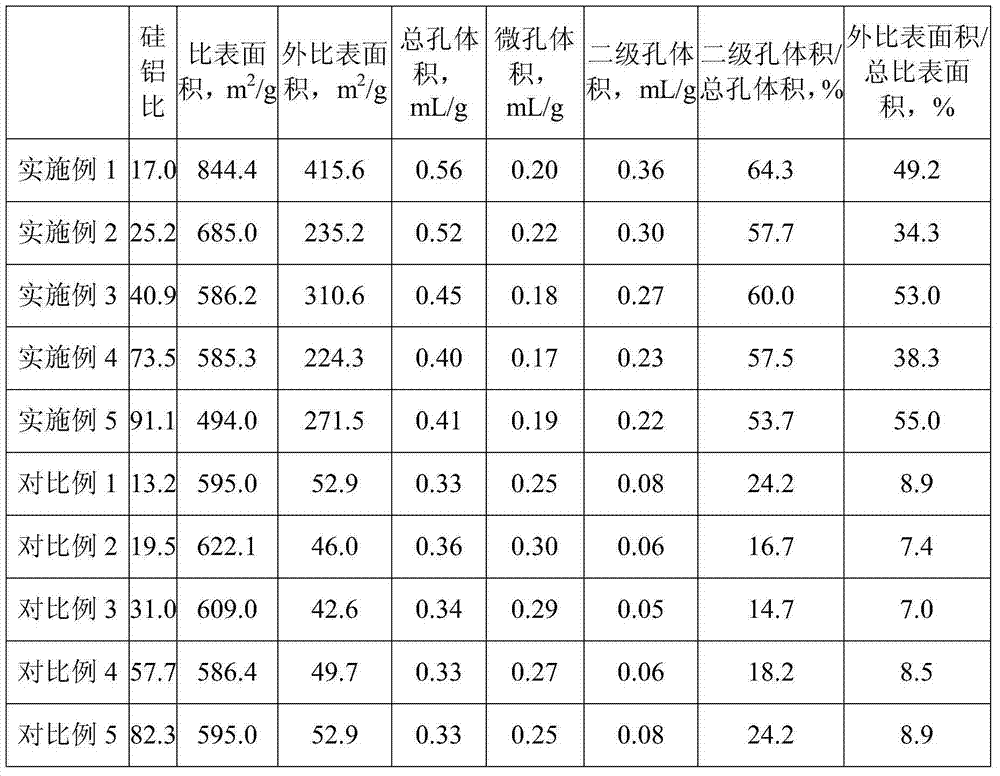

Examples

Embodiment 1

[0043] This embodiment provides a Y-type molecular sieve with ultra-high mesoporous content, which is prepared by the following steps:

[0044] Weigh 20.0g of the NaY zeolite sample that was dried overnight and place it in a quartz reaction tube, inject nitrogen gas, and do a good job of leak detection. After the preparation is completed, set the nitrogen purge rate to 50mL / min (glass rotameter); set The temperature rise program of the reaction furnace: from the initial temperature of 30°C to 500°C after 100 minutes, keep it for 120 minutes; stop heating at this time, and when the temperature naturally drops to 270°C, start to pass SiCl 4 saturated N 2 (N 2 After loading with SiCl 4 Liquid container, in bubble form will be SiCl 4 saturated N 2 Gas carried out), at the same time, after 40 minutes at a heating rate of 4 ℃ / min to 430 ℃, stop feeding SiCl 4 saturated N 2 , alone N 2 Continue to purge for 120 minutes, then stop heating and cool down naturally;

[0045] Ta...

Embodiment 2

[0052] This embodiment provides a Y-type molecular sieve with ultra-high mesoporous content, which is prepared by the following steps:

[0053] Weigh 20.0 g of NH dried overnight 4 The Y zeolite sample is placed in a quartz reaction tube, helium gas is introduced, and the helium gas purge rate is set at 50mL / min (glass rotameter); the heating program of the reaction furnace is set: from the initial temperature of 30°C to 500°C after 100min Keep it for 120 minutes after ℃; stop heating at this time, when the temperature naturally drops to 270 ℃, start to pass SiCl 4 Saturated He, while heating up to 510°C at a heating rate of 4°C / min for 1h, stop feeding SiCl 4 Saturated He, continue purging with He alone for 120min, then stop heating and cool down naturally;

[0054] Take out the sample and wash and dry to obtain DY molecular sieve with high silicon-aluminum ratio;

[0055] Take 10g of DY molecular sieve sample with high silicon-aluminum ratio, add it to 100g of hydrochlori...

Embodiment 3

[0063] This embodiment provides a Y-type molecular sieve with ultra-high mesoporous content, which is prepared by the following steps:

[0064] Weigh 20.0g of the NaY zeolite sample that was dried overnight and place it in a quartz reaction tube, inject nitrogen gas, and do a good job of leak detection. After the preparation is completed, set the nitrogen purge rate to 50mL / min (glass rotameter); Furnace heating program: From the initial temperature of 30°C to 500°C after 100 minutes, keep it for 120 minutes; stop heating at this time, and when the temperature naturally drops to 270°C, start to pass SiCl 4 saturated N 2 At the same time, the temperature was raised to 510°C at a heating rate of 3°C / min for 80 minutes, and the SiCl 4 saturated N 2 After, separate N 2 Continue purging for 120 minutes, then stop heating and cool down naturally. The samples were taken out and washed and dried to obtain a DY molecular sieve with a high silicon-aluminum ratio.

[0065] Take 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com