A Y-type molecular sieve with ultra-high mesoporous content and preparation method thereof

A molecular sieve and mass ratio technology, which is applied in the directions of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc. Effects of hydrothermal stability and enrichment of secondary pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

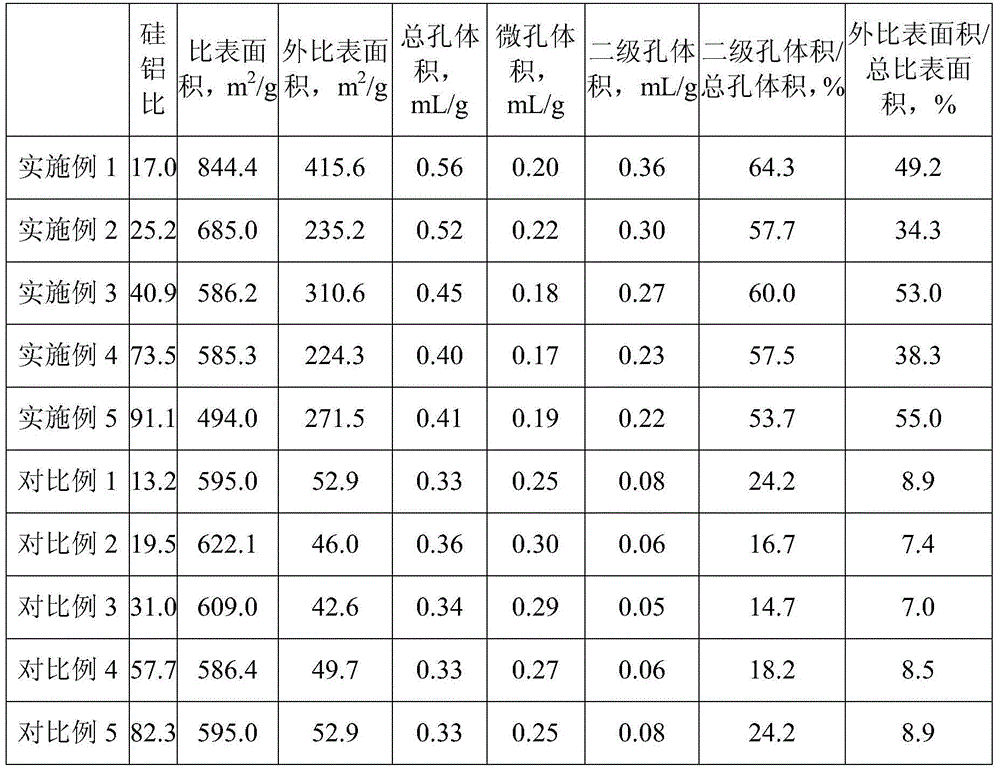

Examples

Embodiment 1

[0043] This embodiment provides a Y-type molecular sieve with ultra-high mesopore content, which is prepared by the following steps:

[0044] Weigh 20.0g of NaY zeolite sample dried overnight and place it in a quartz reaction tube, pour nitrogen into it, and do leak detection work. After preparation, set the nitrogen purge speed to 50mL / min (glass rotor flowmeter); set The heating program of the reaction furnace: from the starting temperature of 30°C to 500°C for 100 minutes and then holding for 120 minutes; stop heating at this time, and when the temperature naturally drops to 270°C, the SiCl 4 Saturated N 2 (N 2 After equipped with SiCl 4 The liquid container will be SiCl in the form of bubbling 4 Saturated N 2 The gas is brought out), and at the same time the temperature is increased to 430°C at a heating rate of 4°C / min for 40 minutes, and then the flow of SiCl is stopped. 4 Saturated N 2 , Alone N 2 Continue to purge for 120 minutes, then stop heating and cool down naturally; ...

Embodiment 2

[0052] This embodiment provides a Y-type molecular sieve with ultra-high mesopore content, which is prepared by the following steps:

[0053] Weigh 20.0g dried overnight NH 4 The Y zeolite sample is placed in a quartz reaction tube, helium is introduced, and the helium purge speed is set to 50mL / min (glass rotameter); the heating program of the reaction furnace is set: the starting temperature is 30℃ and the temperature is raised to 500 after 100min Keep for 120min after ℃; stop heating at this time, when the temperature naturally cools to 270℃, start to pass in SiCl 4 The saturated He is heated to 510°C at a heating rate of 4°C / min for 1h, and then the flow of SiCl is stopped. 4 Saturated He, He alone continues to purge for 120 minutes, then stop heating and cool down naturally;

[0054] Take out the sample and wash and dry to obtain DY molecular sieve with high silicon to aluminum ratio;

[0055] Take 10g sample of DY molecular sieve with high silicon-to-aluminum ratio, add it to 1...

Embodiment 3

[0063] This embodiment provides a Y-type molecular sieve with ultra-high mesopore content, which is prepared through the following steps:

[0064] Weigh 20.0g of NaY zeolite sample dried overnight and place it in a quartz reaction tube, pour nitrogen into it, and do the leak detection work. After preparation, set the nitrogen purge rate to 50mL / min (glass rotor flowmeter); set the reaction Furnace temperature rising program: after 100 minutes from the starting temperature of 30 ℃ to 500 ℃, keep for 120 minutes; stop heating at this time, when the temperature naturally cools down to 270 ℃, start to pass the SiCl 4 Saturated N 2 At the same time, the temperature is increased to 510°C at a rate of 3°C / min for 80min, and the flow of SiCl is stopped. 4 Saturated N 2 After, alone N 2 Continue to purge for 120 minutes, then stop heating and cool down naturally. The sample was taken out and washed and dried to obtain DY molecular sieve with high silicon to aluminum ratio.

[0065] Take 10g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com