Medium oil type hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, which is applied in the field of medium oil type hydrocracking catalyst and its preparation, can solve the problems of large decrease in crystallinity, and achieve the effects of small unit cell parameters, improved utilization rate, and high silicon-to-aluminum ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

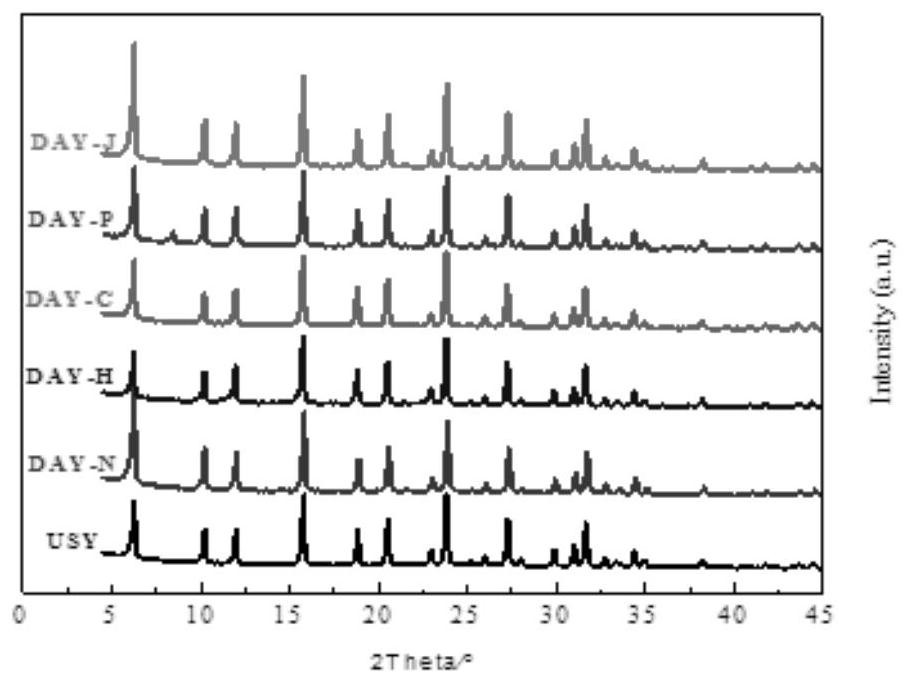

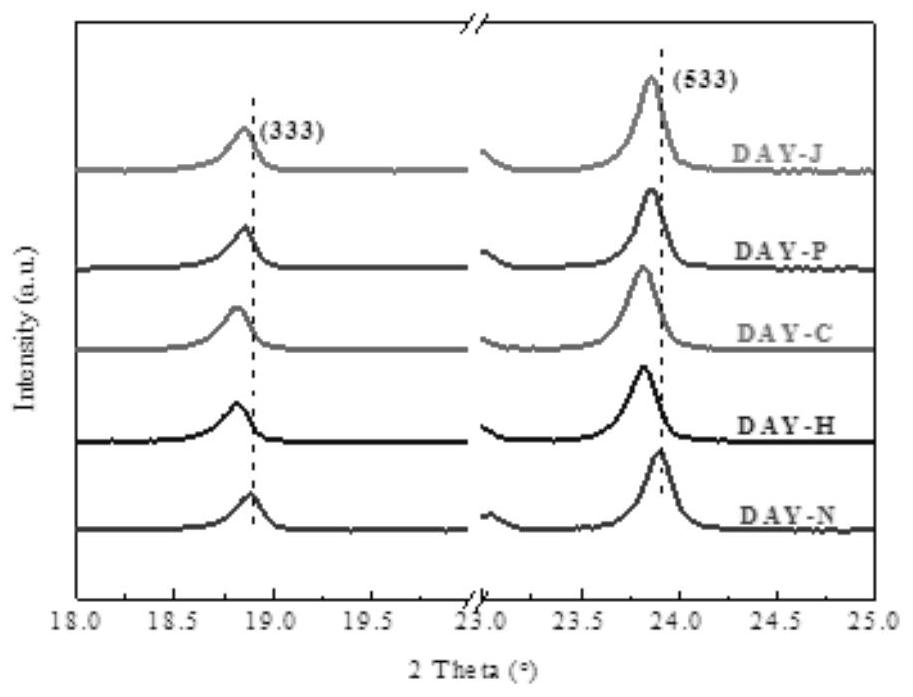

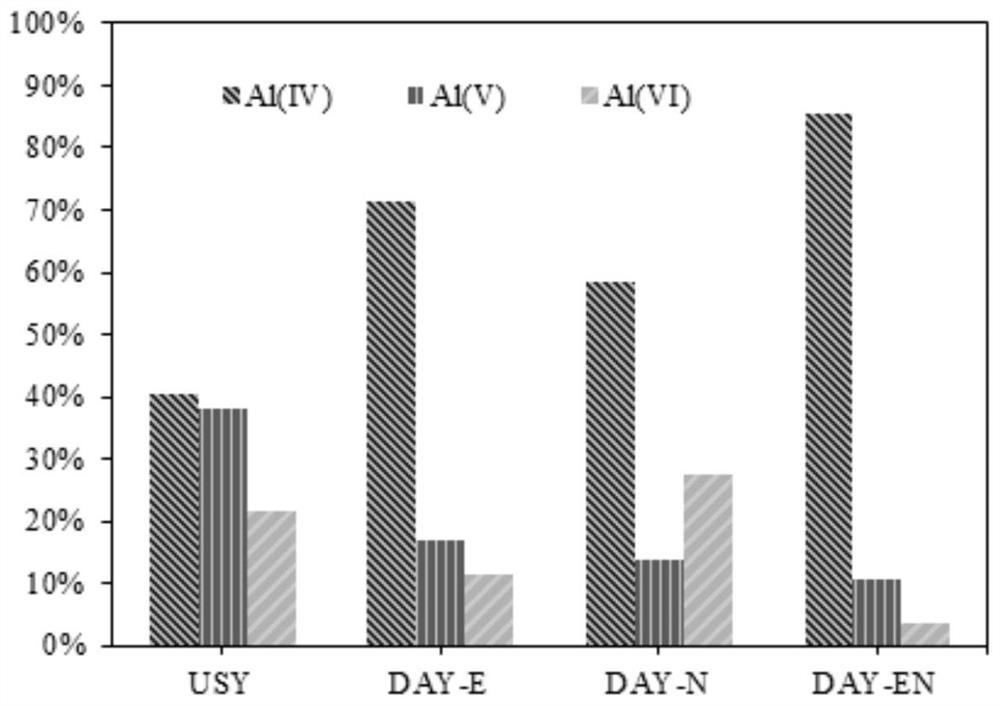

[0050] In this example, the selection of organic acid components in the composite modifier was investigated. Five common organic acids, tartaric acid, citric acid, oxalic acid, succinic acid and malic acid, were used. type molecular sieve for processing. "USY" stands for commercial ultra-stable Y-type molecular sieve, "DAY-N", "DAY-H", "DAY-C", "DAY-P", "DAY-J" stand for citric acid, succinic acid, respectively , oxalic acid, malic acid, tartaric acid to treat the samples prepared by Y-type molecular sieve.

Embodiment 1-1

[0052] At room temperature, add 5g of industrial USY molecular sieve into a 250mL three-necked flask, and then add 25mL of 0.3mol·L -1 The citric acid solution was vigorously stirred at 80°C for 4h. After the reaction was completed, the obtained milky white suspension was filtered, washed to neutrality, and dried at 110° C. for 12 h to obtain acid-modified Y-type molecular sieve. See Table 1 for its specific surface area and pore structure. Sample number "DAY-N".

Embodiment 1-2 to Embodiment 1-5

[0054] The only difference from Example 1-1 is that the citric acid solution was replaced with a succinic acid solution, an oxalic acid solution, a malic acid solution, and a tartaric acid solution in sequence. The sample numbers are "DAY-H", "DAY-C", "DAY-P", "DAY-J".

[0055] Table 1 Specific surface area and pore structure data of molecular sieves

[0056]

[0057]

[0058] From the results in Table 1, it can be seen that the use of organic acid to treat Y-type molecular sieve can effectively remove molecular sieve framework aluminum, and all can play the role of pore expansion. The acid strength of several organic acids is from high to low: oxalic acid, citric acid, Tartaric acid, malic acid, succinic acid. Appropriate concentration ratios need to be used for different organic acids to avoid excessive dealumination causing the collapse of the molecular sieve framework. For example, in this example, the content of micropores in most of the samples is higher than tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com